Definitions

🔜Value Engineering:-is a technique applied to identifying optimum value solutions during new product development.

🔜Value analysis:- is a technique applied to improving existing products, processesor services.

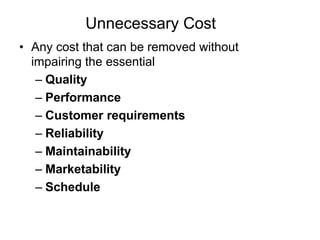

🔜The objective is usually to reduce cost, but may equally or simultaneously be to improve performance or quality.

-LDMiles

The Key Points of VA /VE

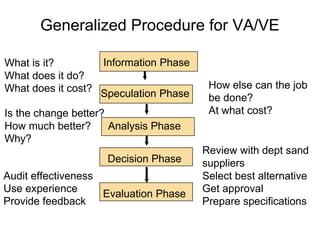

• Applying formal workplans.

• A team approach.

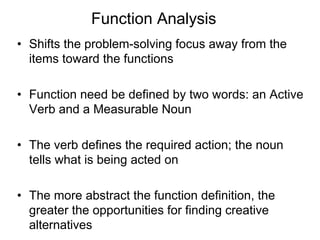

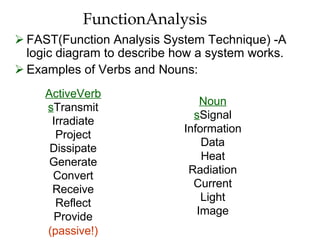

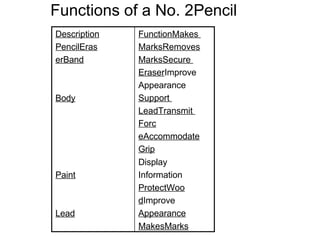

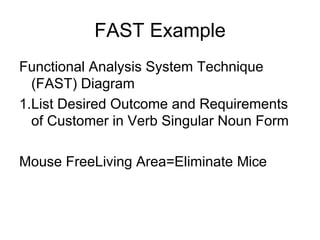

• Specific definition of functions.

• The simultaneous look at functions and costs.

• Control of the analysis process.

• Quantifiable results

What is VE?

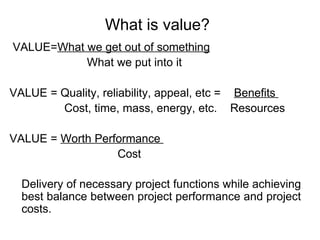

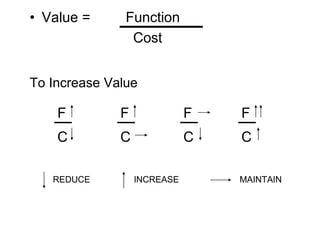

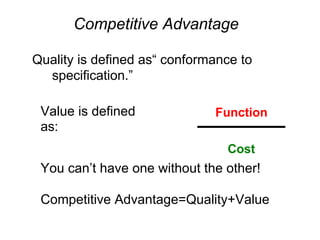

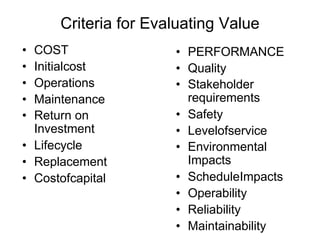

Value is the relationship between the defined function the customer requires and the costs incurred to provide that function.

– Cost Value

– Use Value

– Esteem Value

– Exchange Value

Value Engineering

🔜Value Engineering is:

• Reliability

• Maintainability

• Producibility

• Human Factors

• Parts Availability

• CycleTime

• Quality

• Weight Reduction

Definitions

🔜Value Engineering:-is a technique applied to identifying optimum value solutions during new product development.

🔜Value analysis:- is a technique applied to improving existing products, processesor services.

🔜The objective is usually to reduce cost, but may equally or simultaneously be to improve performance or quality.

-LDMiles

The Key Points of VA /VE

• Applying formal workplans.

• A team approach.

• Specific definition of functions.

• The simultaneous look at functions and costs.

• Control of the analysis process.

• Quantifiable results

What is VE?

Value is the relationship between the defined function the customer requires and the costs incurred to provide that function.

– Cost Value

– Use Value

– Esteem Value

– Exchange Value

Value Engineering

🔜Value Engineering is:

• Reliability

• Maintainability

• Producibility

• Human Factors

• Parts Availability

• CycleTime

• Quality

• Weight Reduction

Definitions

🔜Value Engineering:-is a technique applied to identifying optimum value solutions during new product development.

🔜Value analysis:- is a technique applied to improving existing products, processesor services.

🔜The objective is usually to reduce cost, but may equally or simultaneously be to improve performance or quality.

-LDMiles

The Key Points of VA /VE

• Applying formal workplans.

• A team approach.

• Specific definition of functions.

• The simultaneous look at functions and costs.

• Control of the analysis process.

• Quantifiable results

What is VE?

Value is the relationship between the defined function the customer requires and the costs incurred to provide that function.

– Cost Value

– Use Value

– Esteem Value

– Exchange Value

Value Engineering

🔜Value Engineering is:

• Reliability

• Maintainability

• Producibility

• Human Factors

• Parts Availability

• CycleTime

• Quality

• Weight Reduction

Definitions

🔜Value Engineering:-is a technique applied to identifying optimum value solutions during new product development.

🔜Value analysis:- is a technique applied to improving existing products, pr