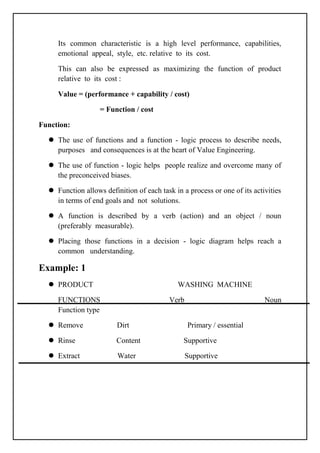

Value analysis and value engineering are techniques used to increase the value of products, processes, and projects. Value analysis focuses on existing products and value engineering focuses on new products during development. Both techniques involve identifying necessary functions, establishing the value of each function, and finding ways to deliver necessary functions at the lowest total cost over the product's life cycle. The value analysis process involves an eight-step job plan to systematically analyze products and identify opportunities to improve value. The objectives are to reduce costs while maintaining or improving necessary functions.