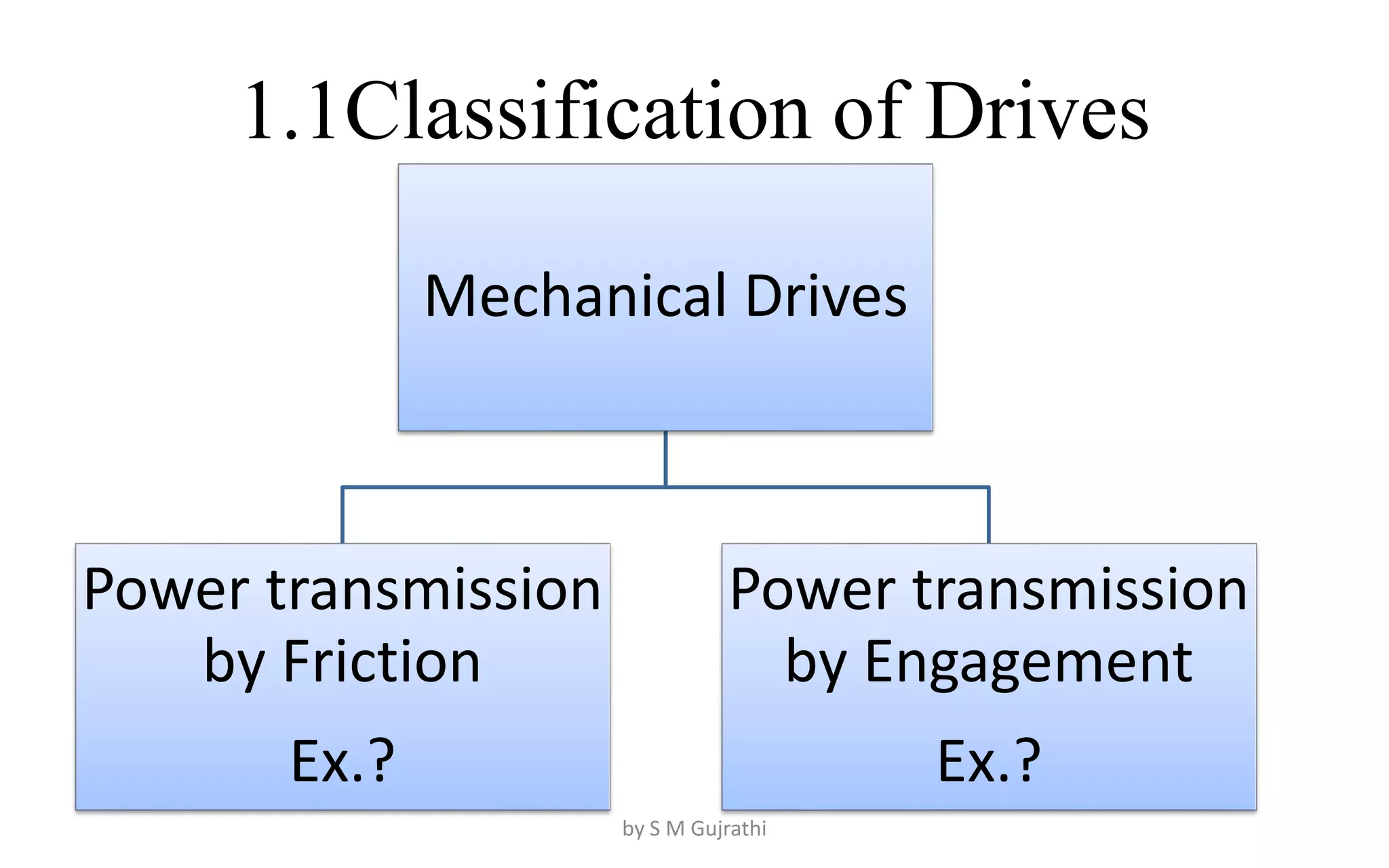

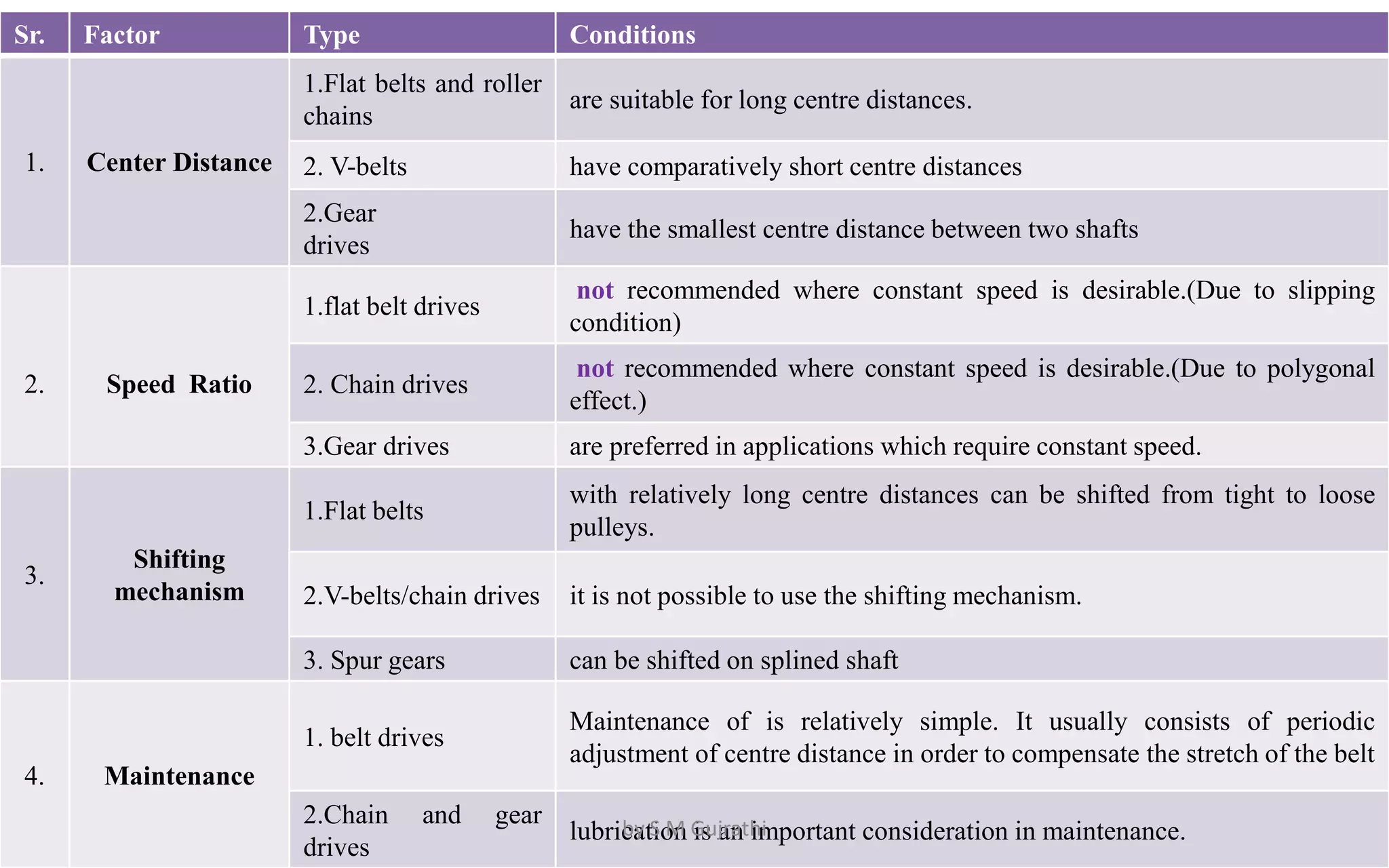

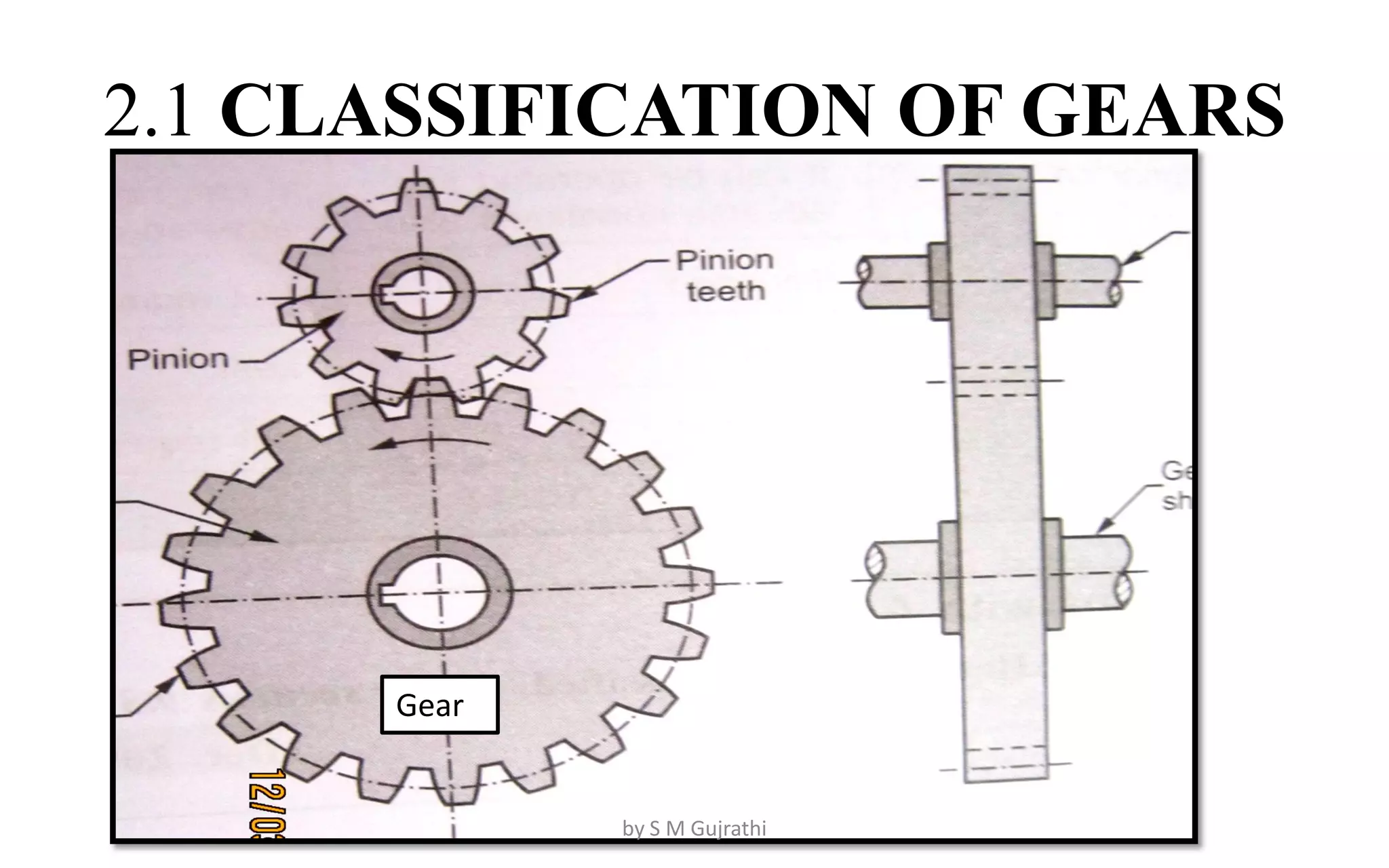

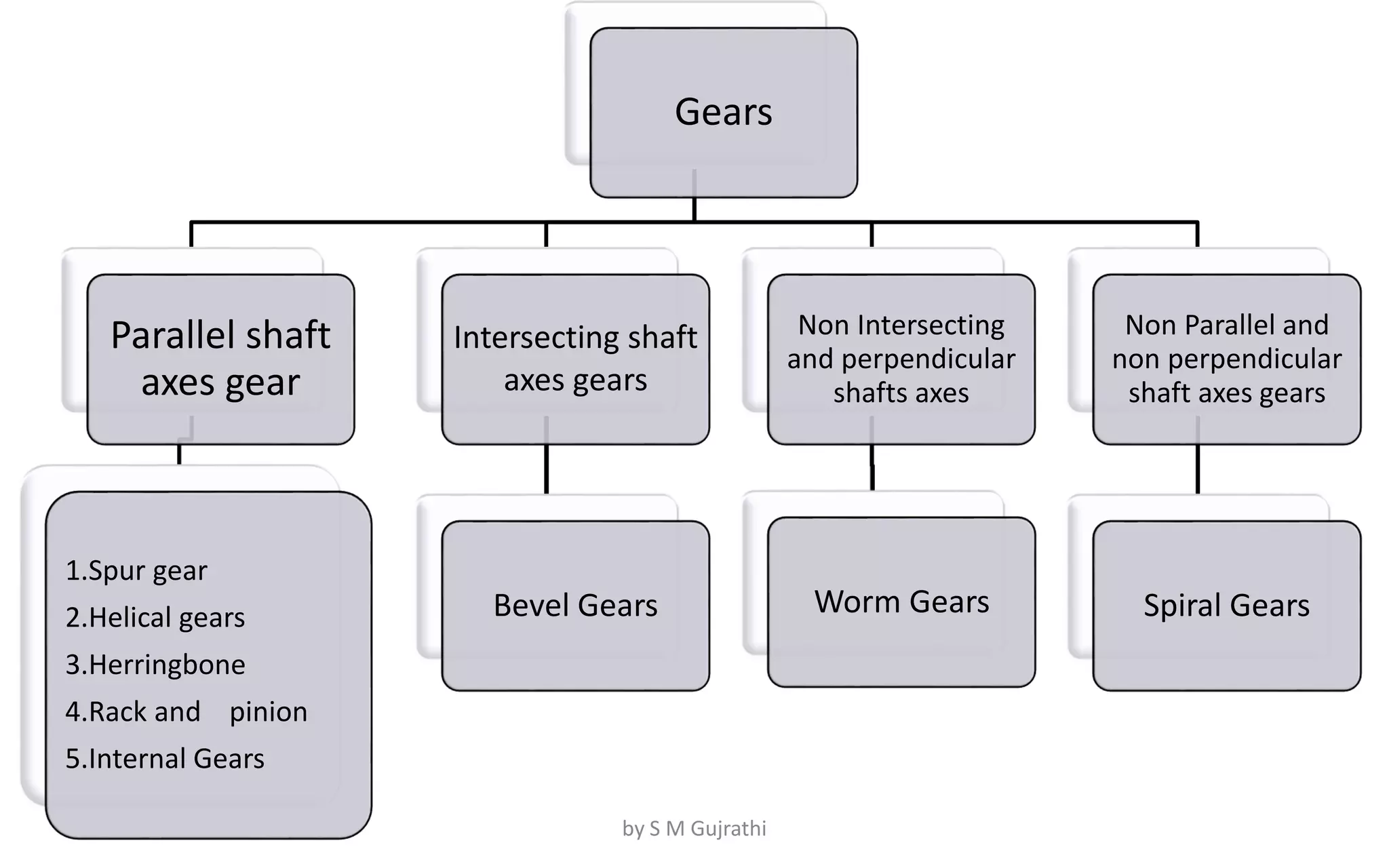

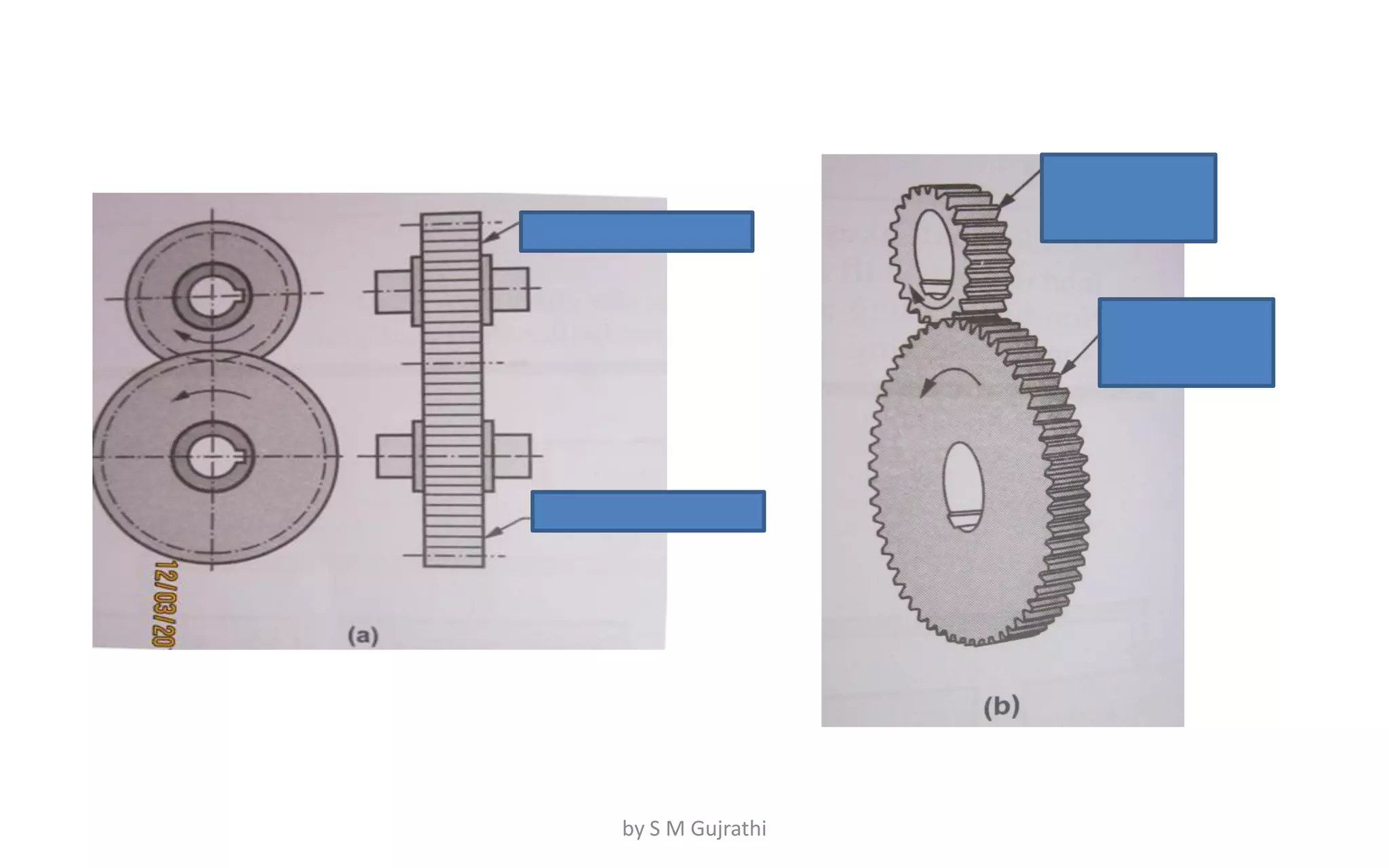

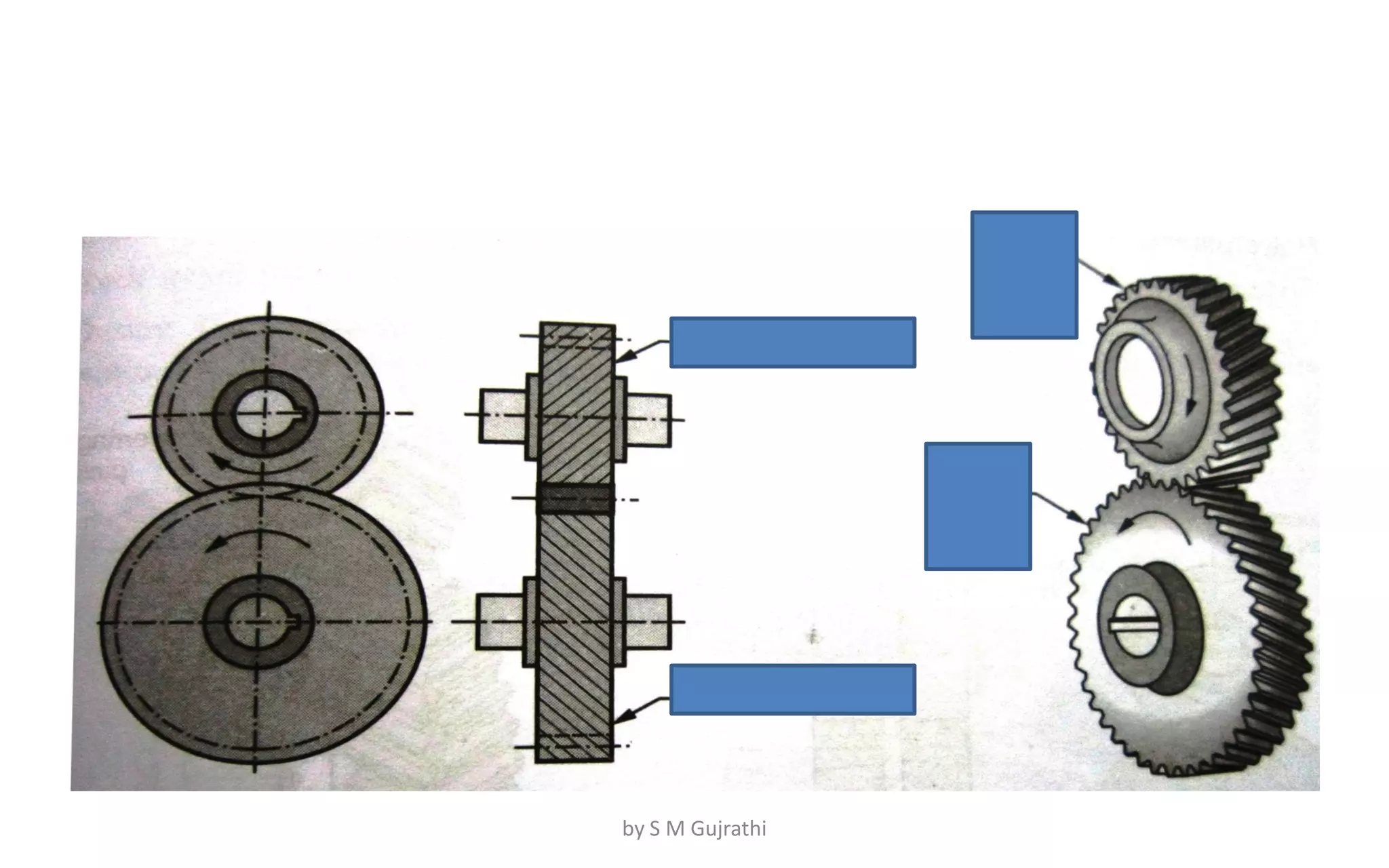

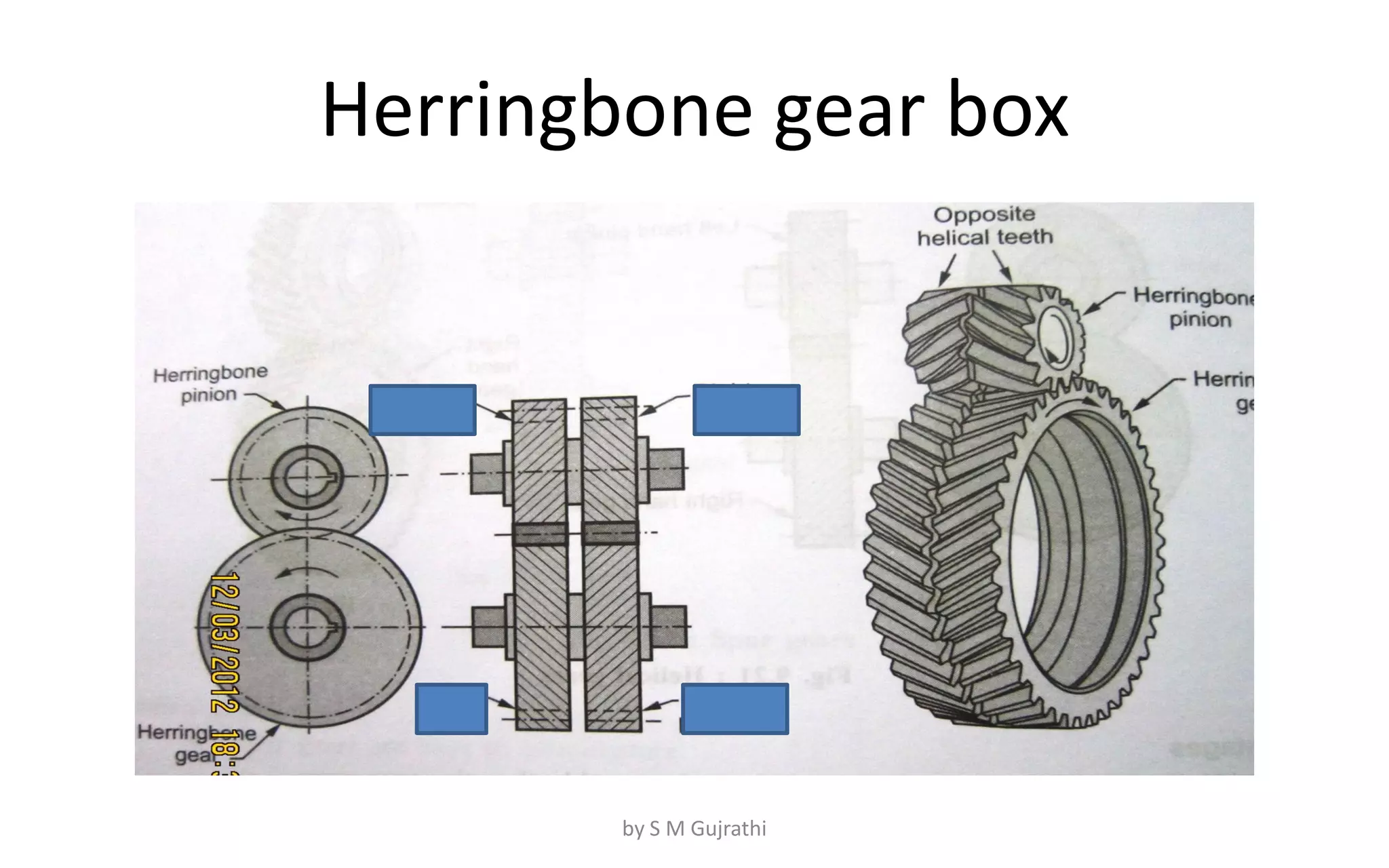

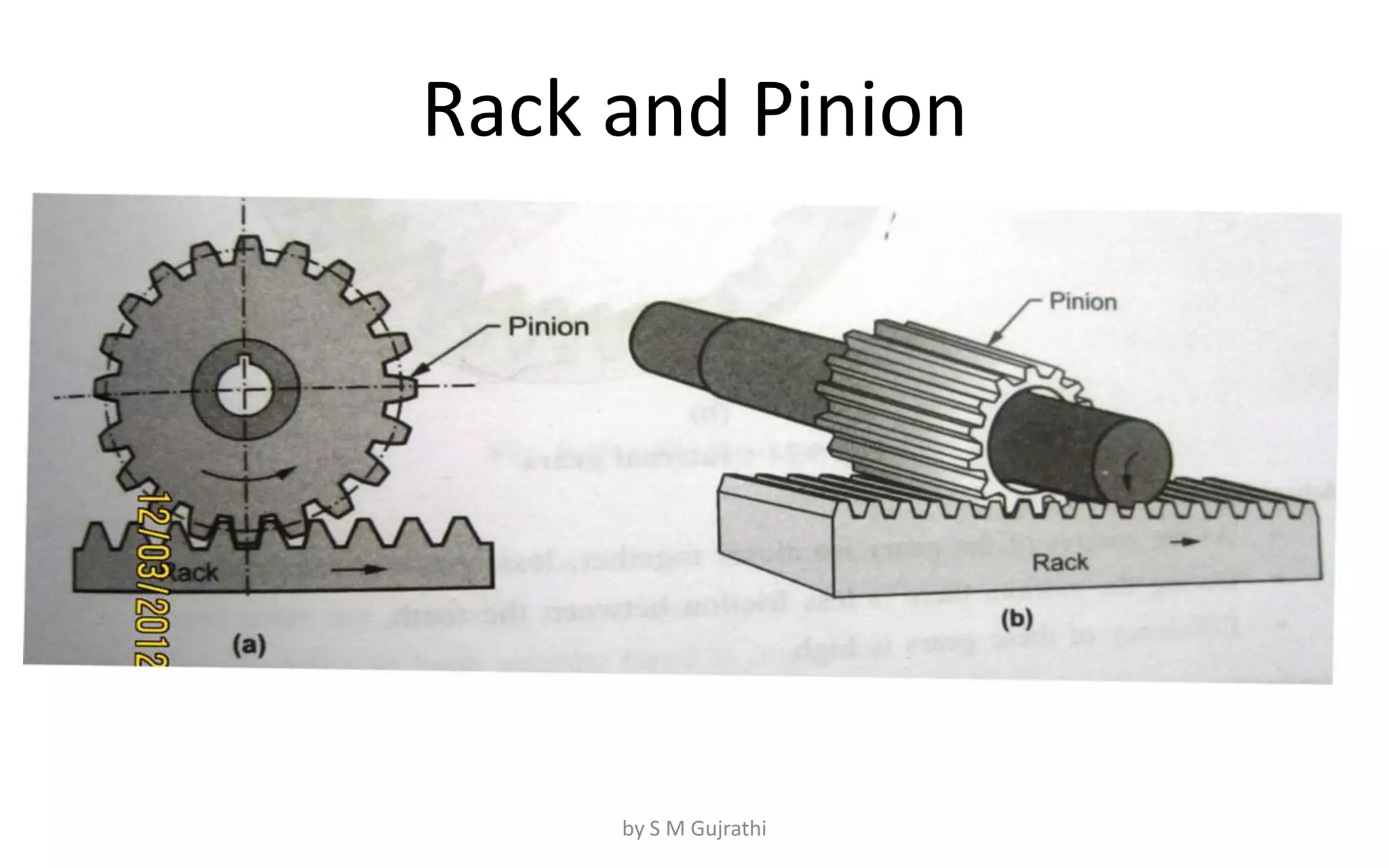

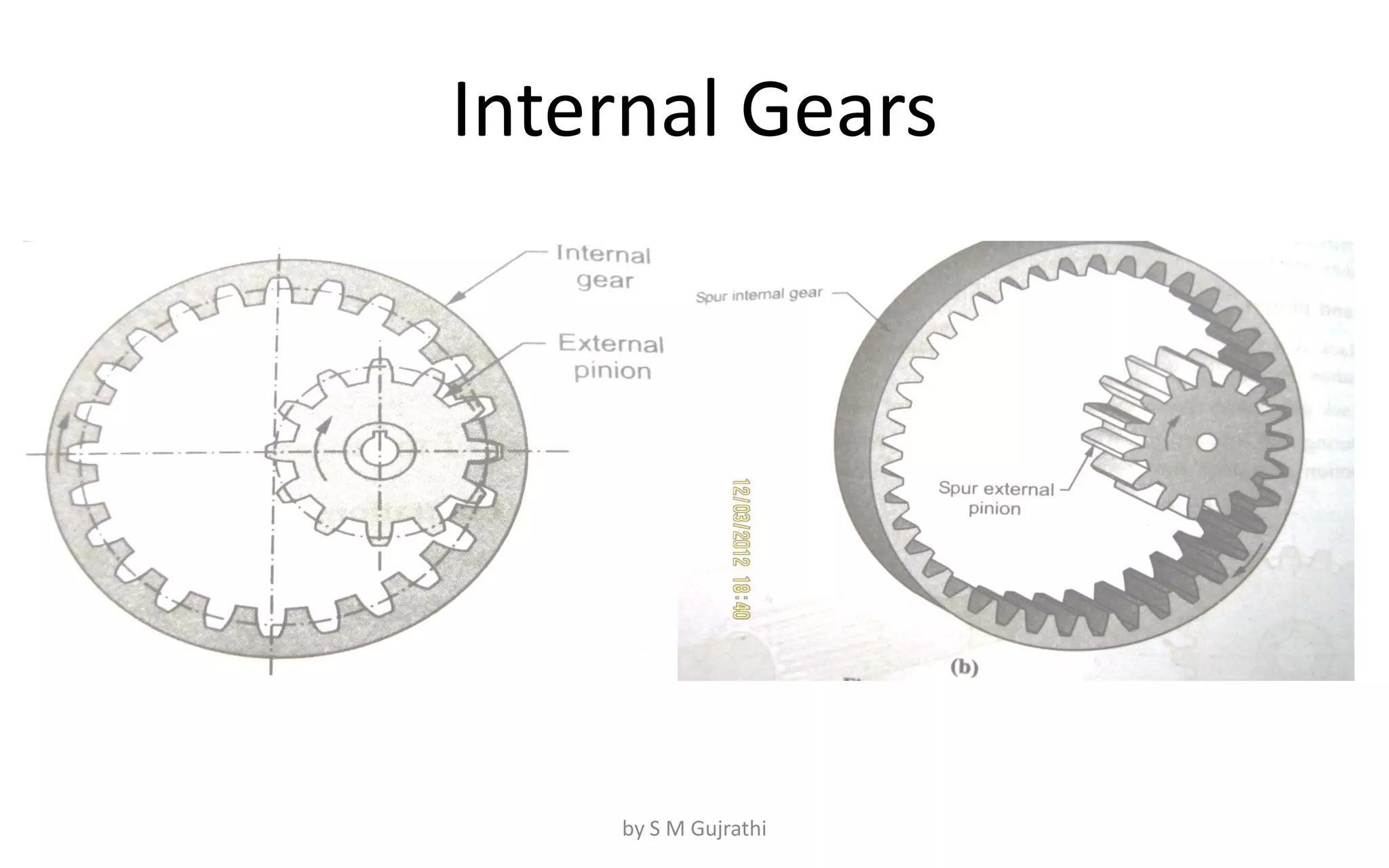

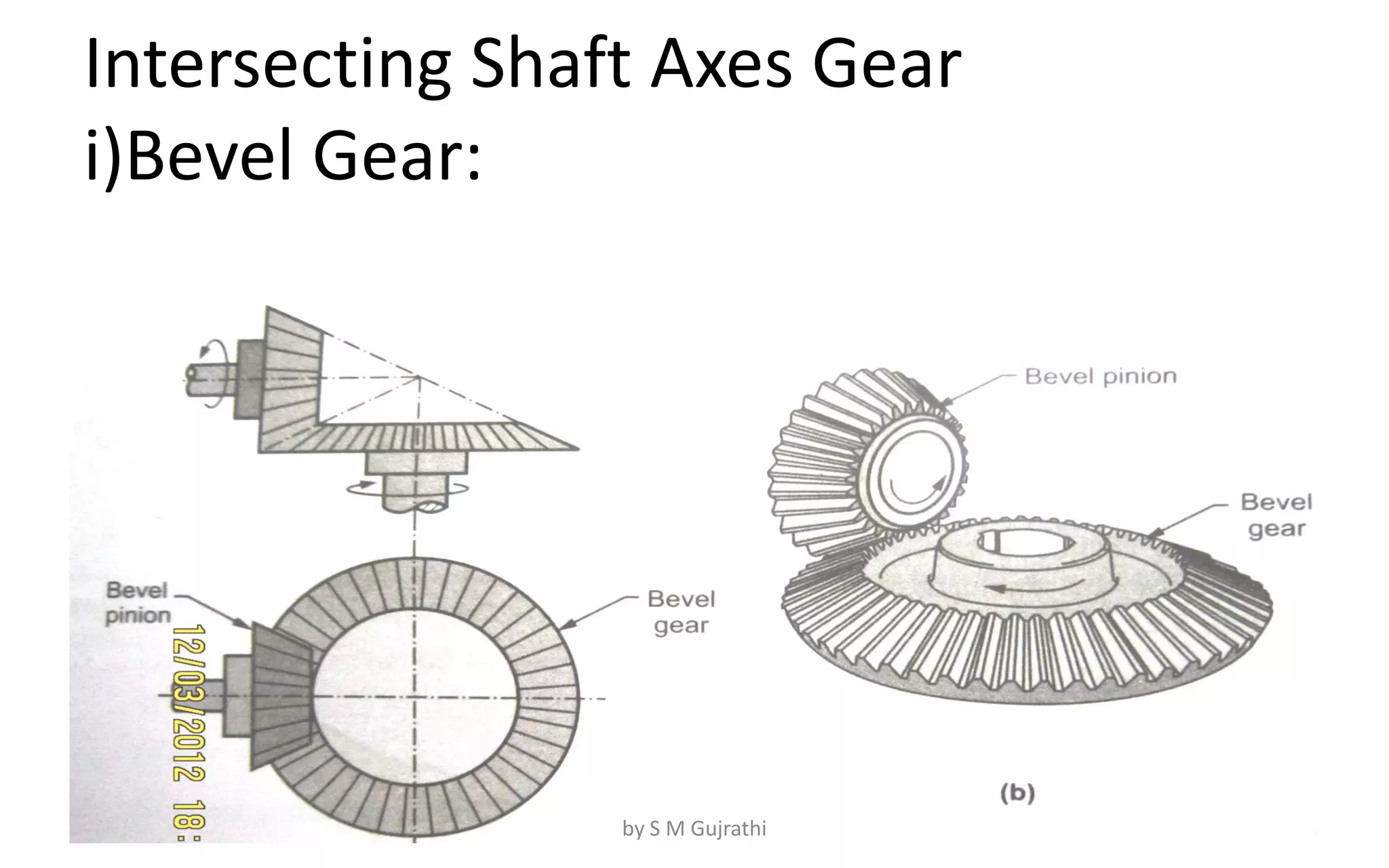

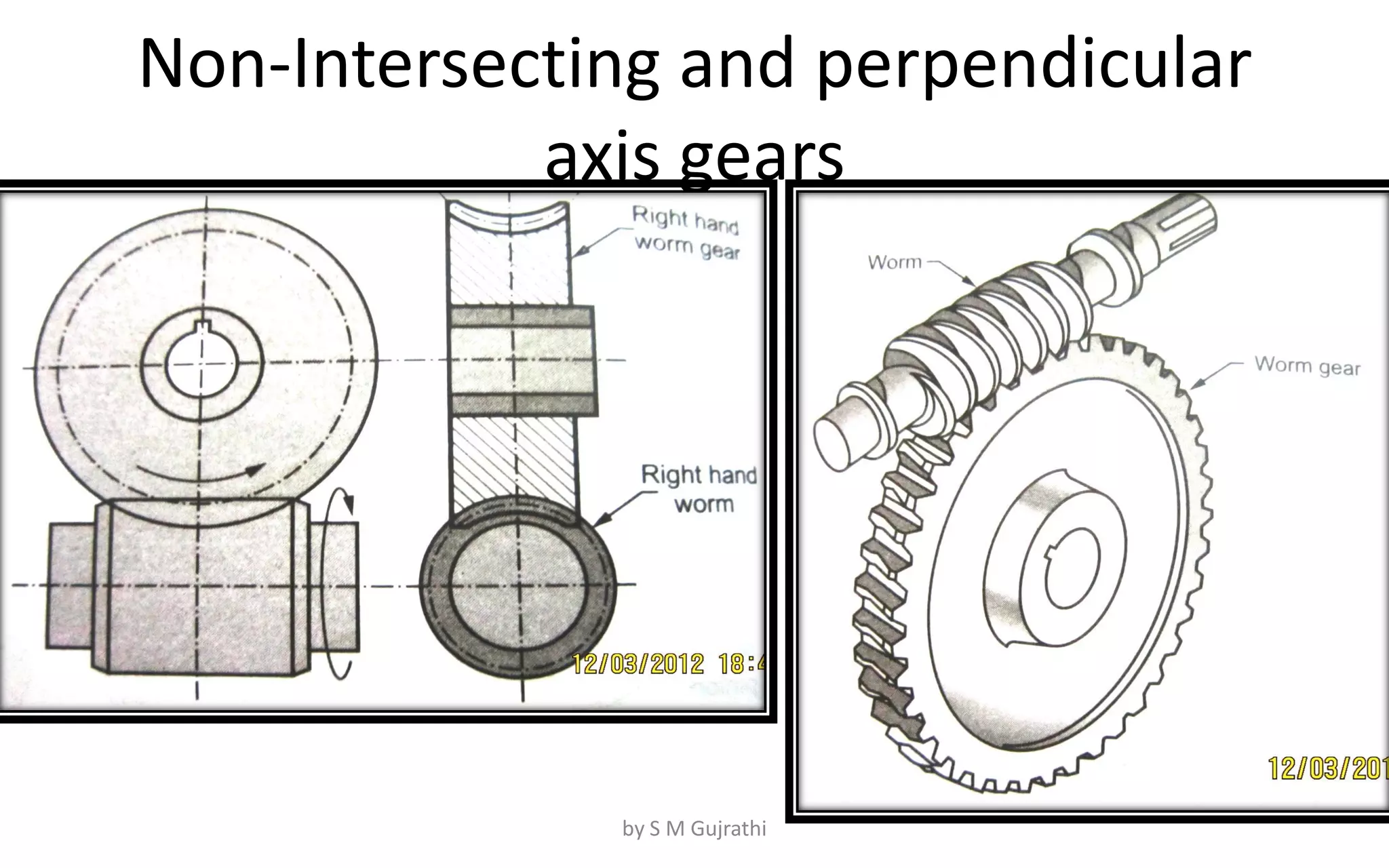

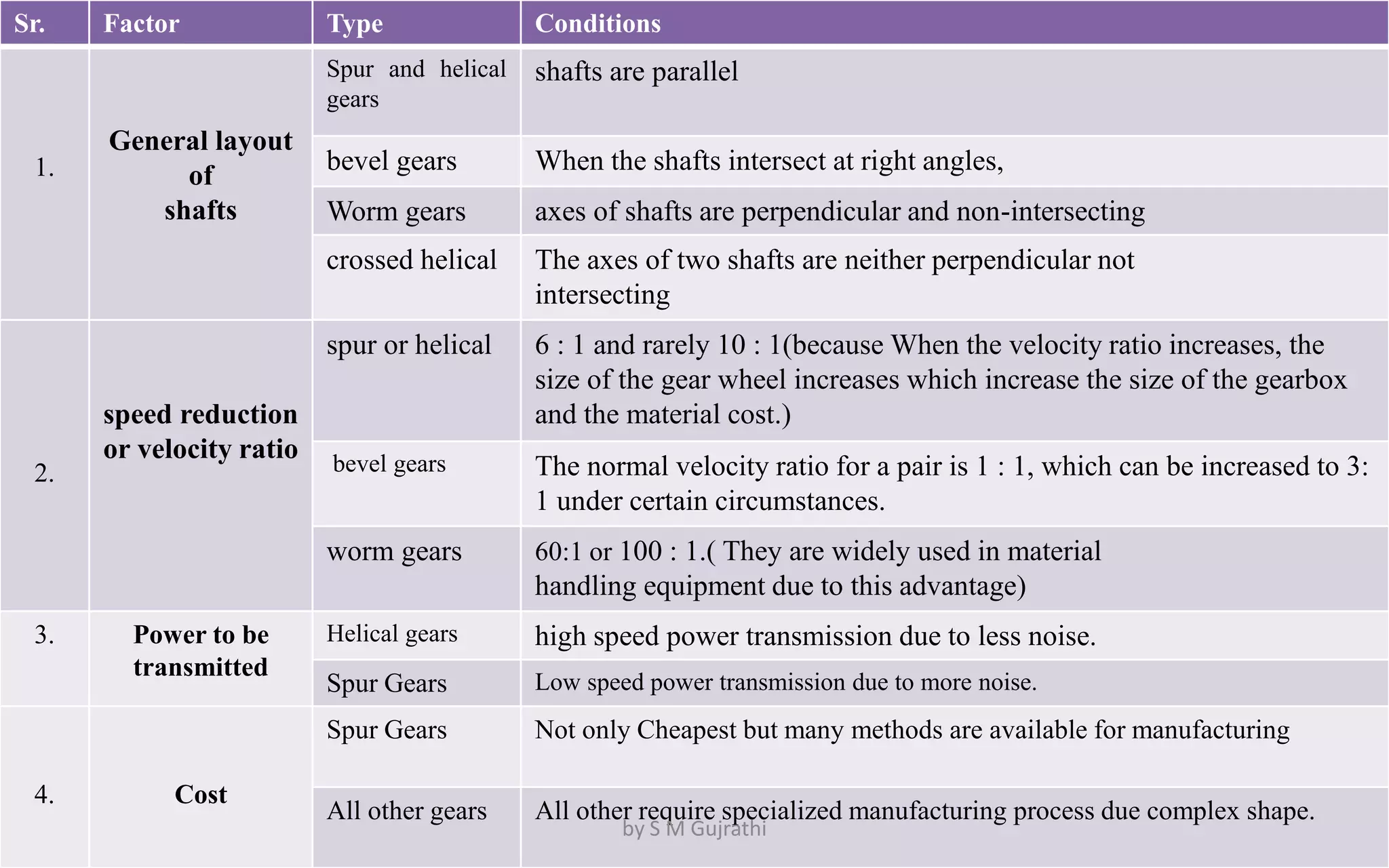

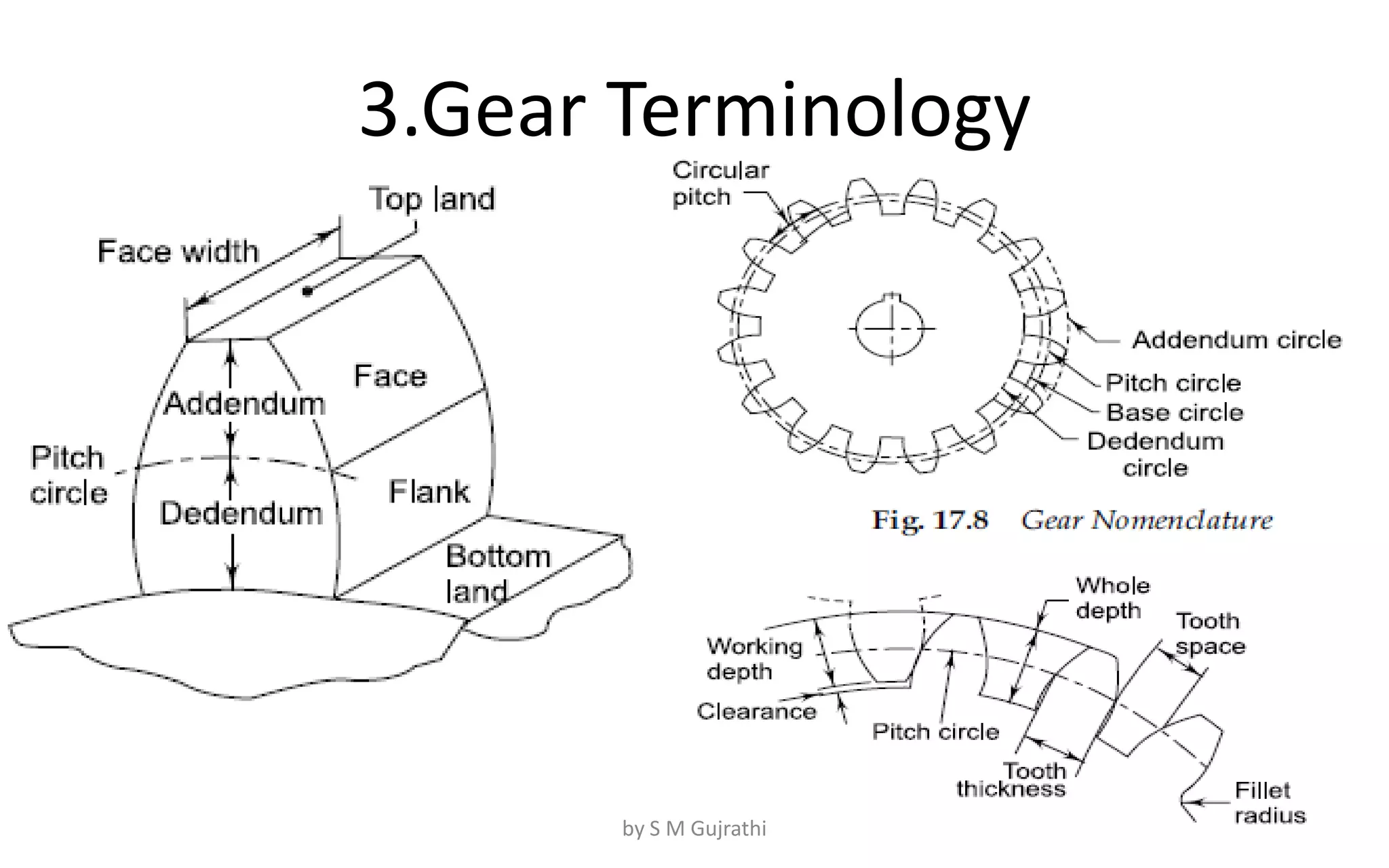

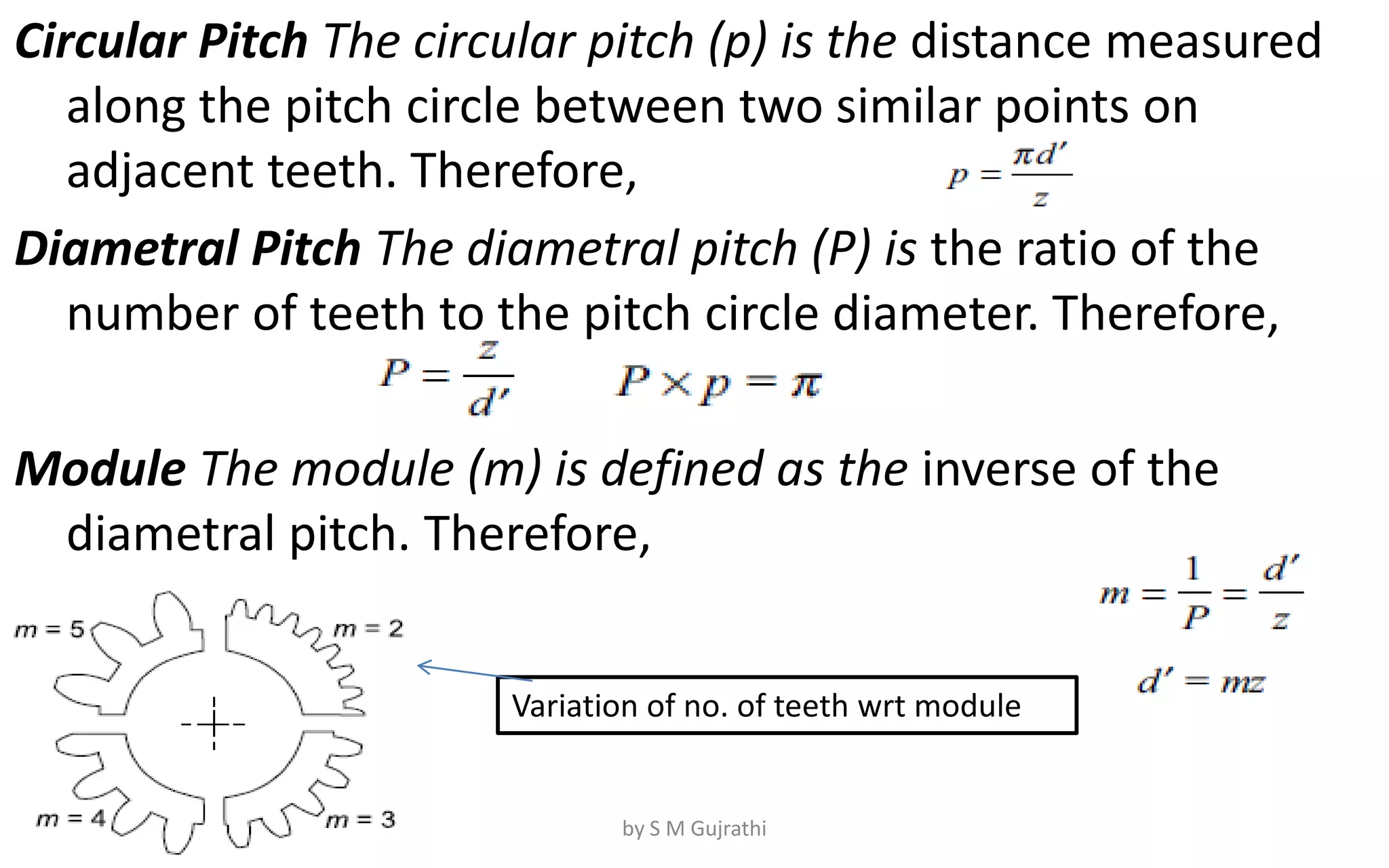

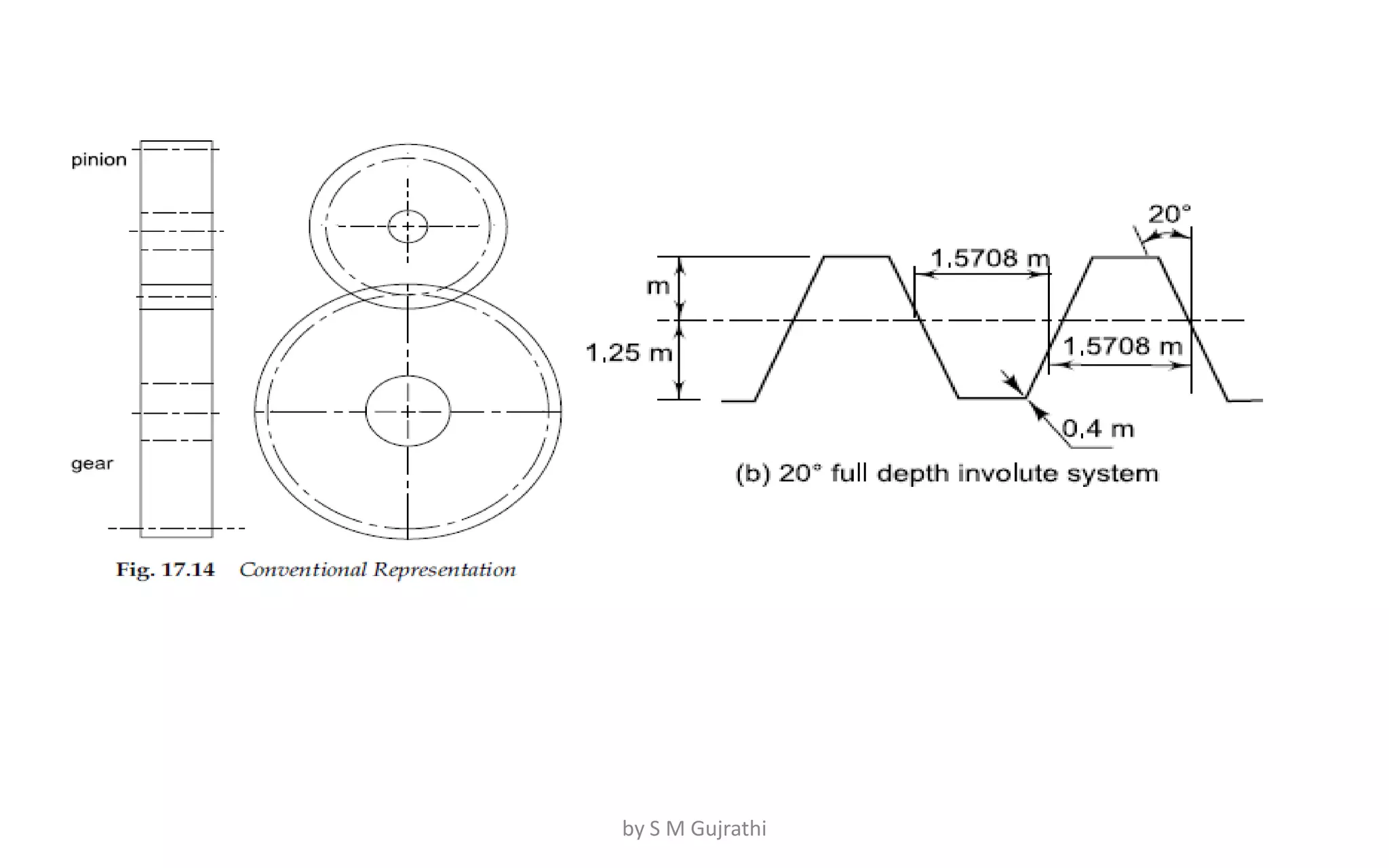

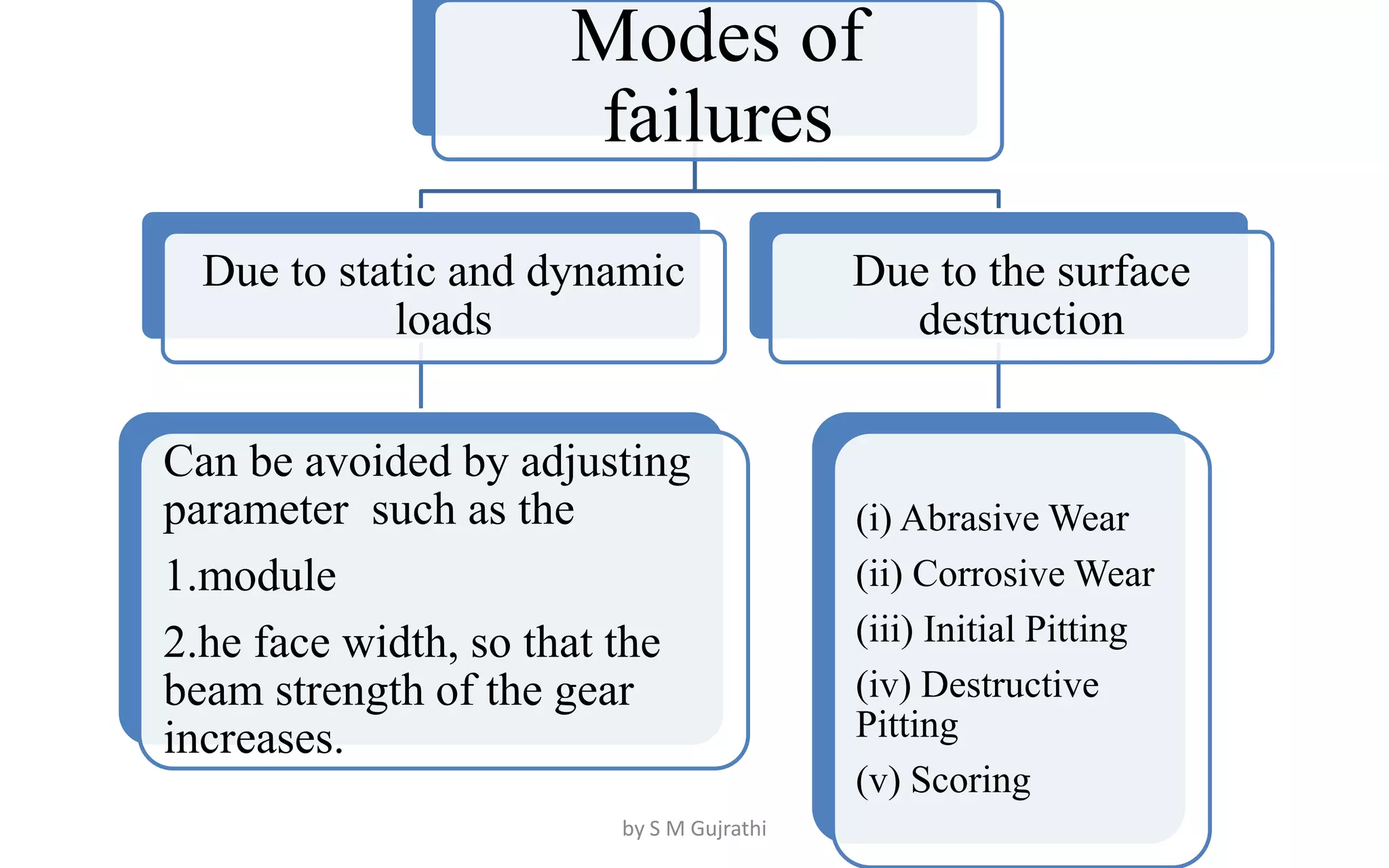

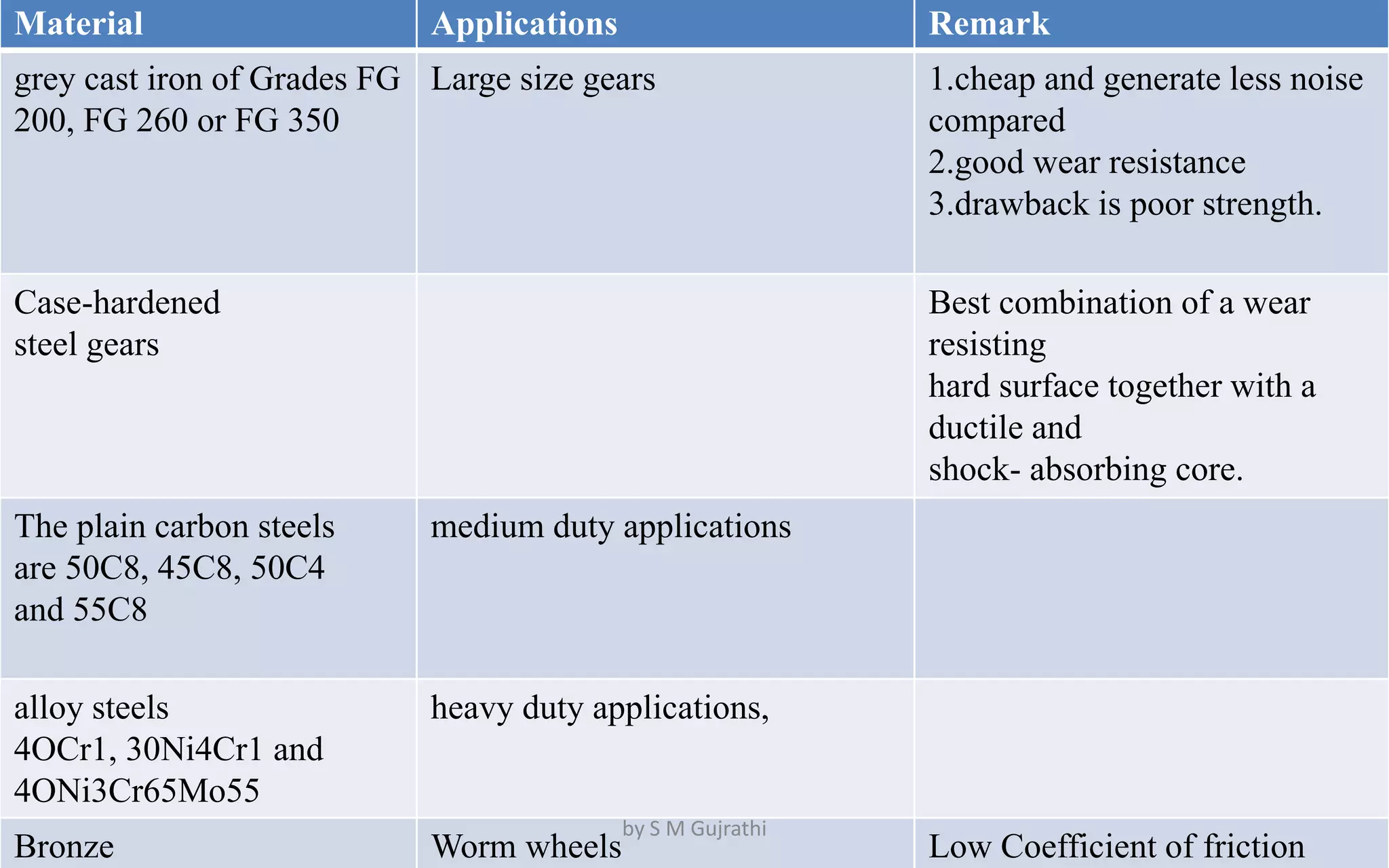

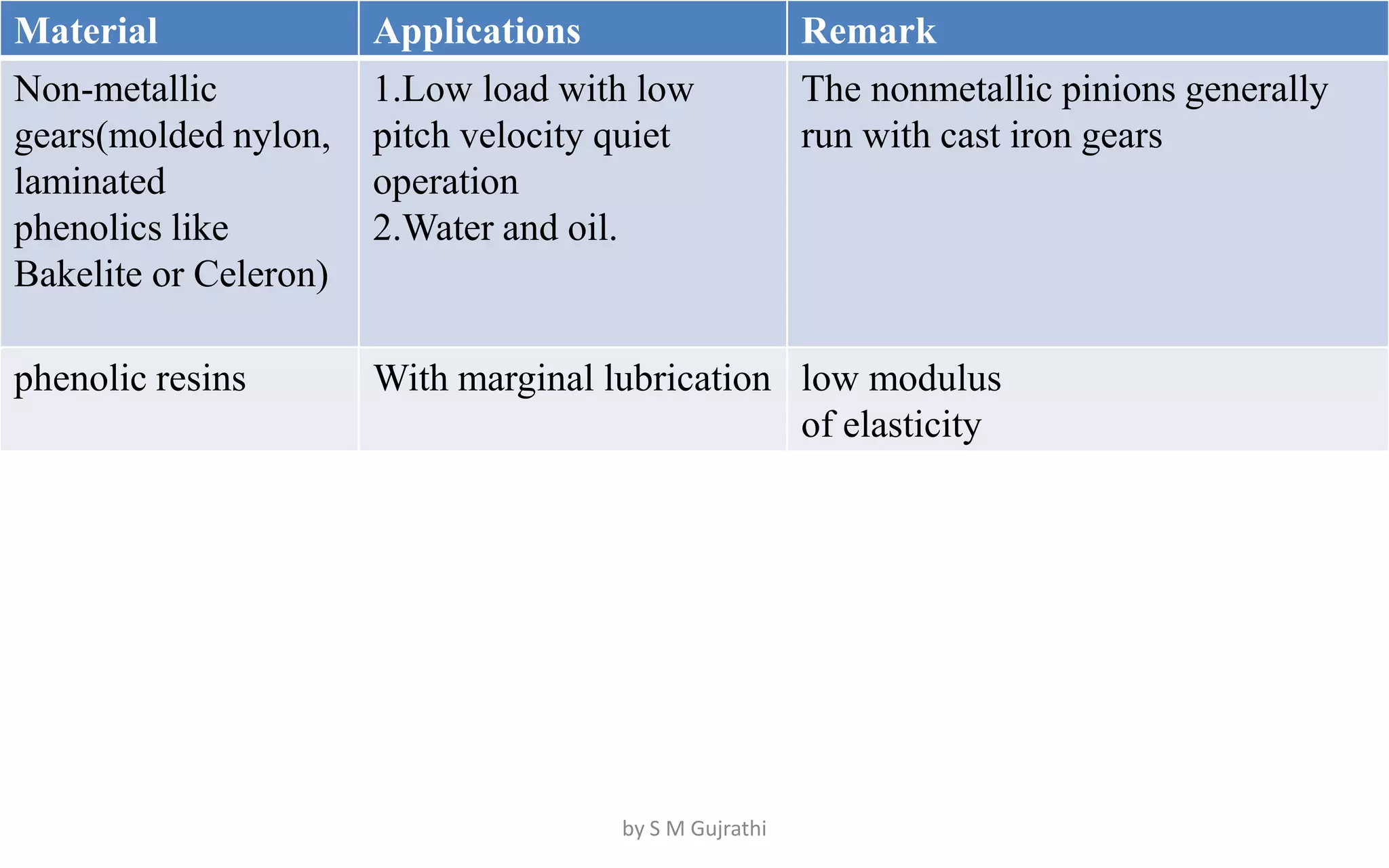

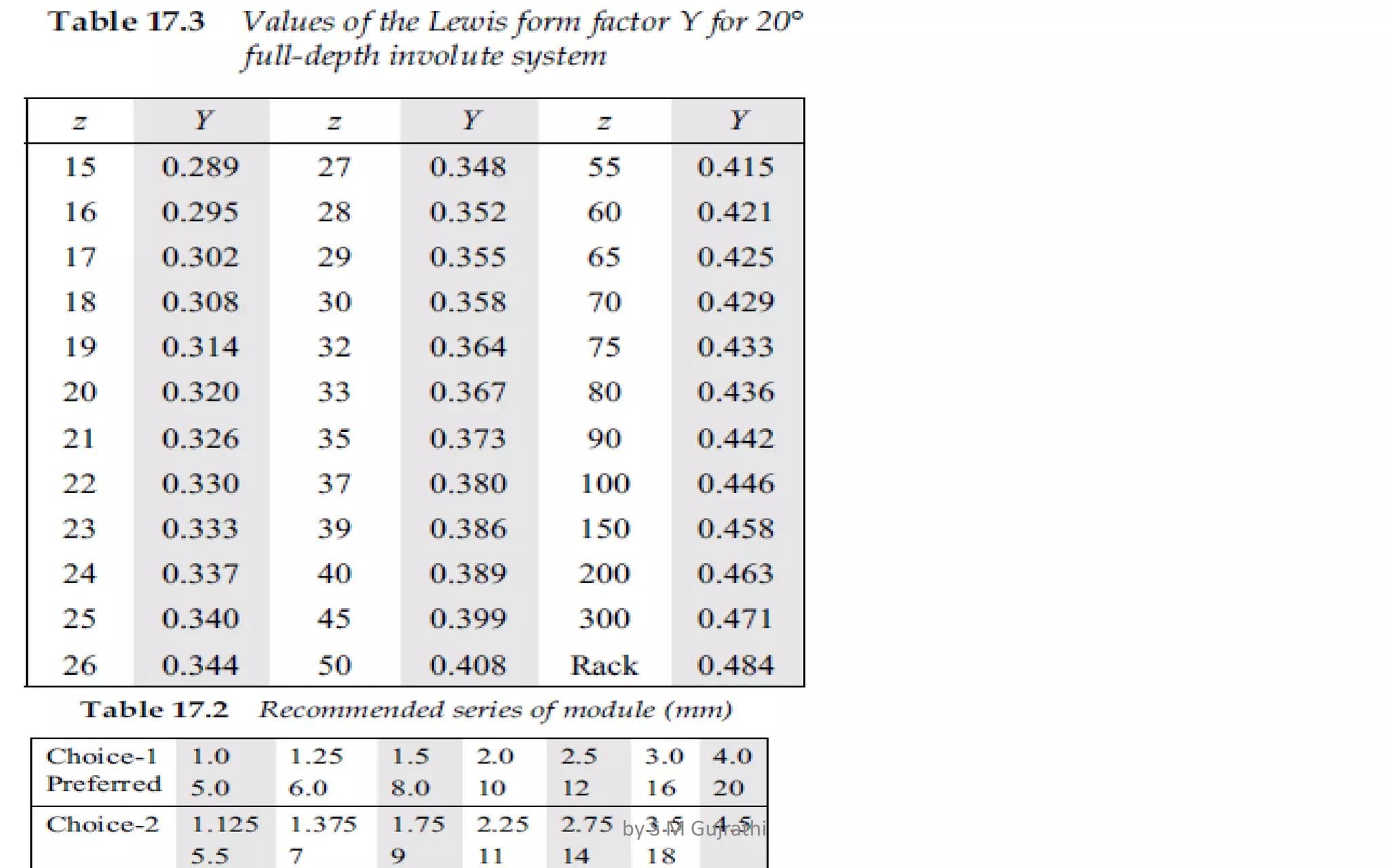

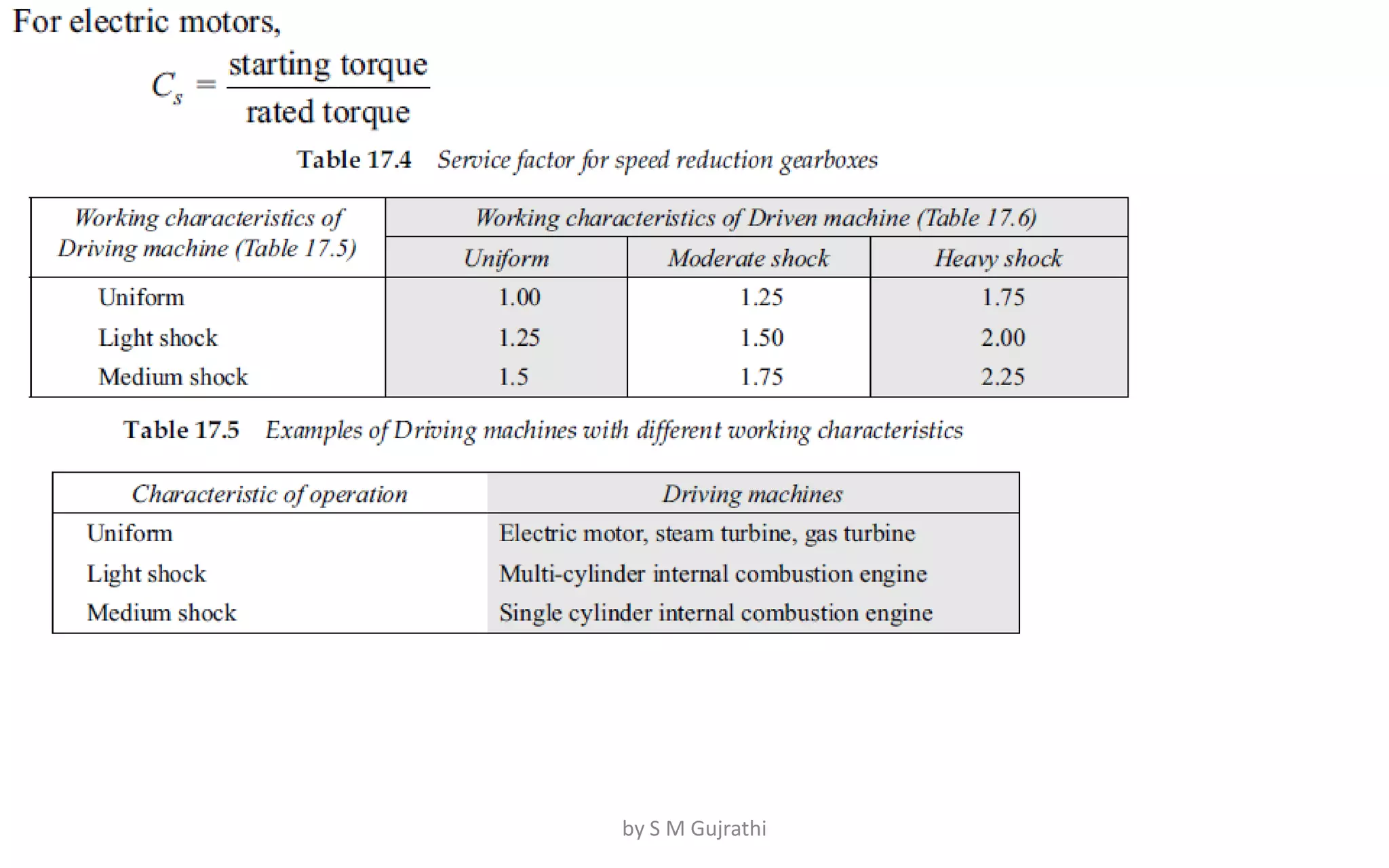

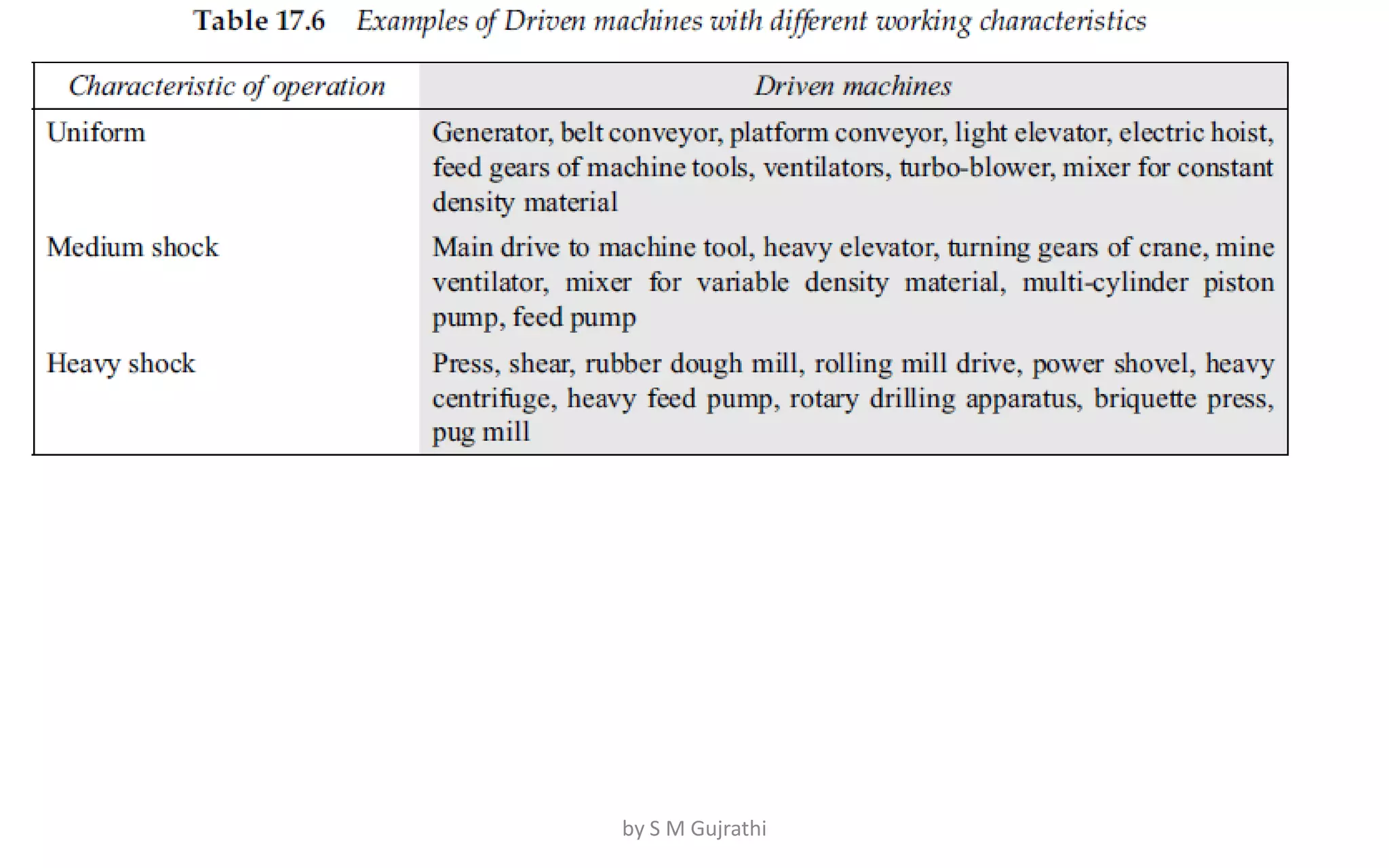

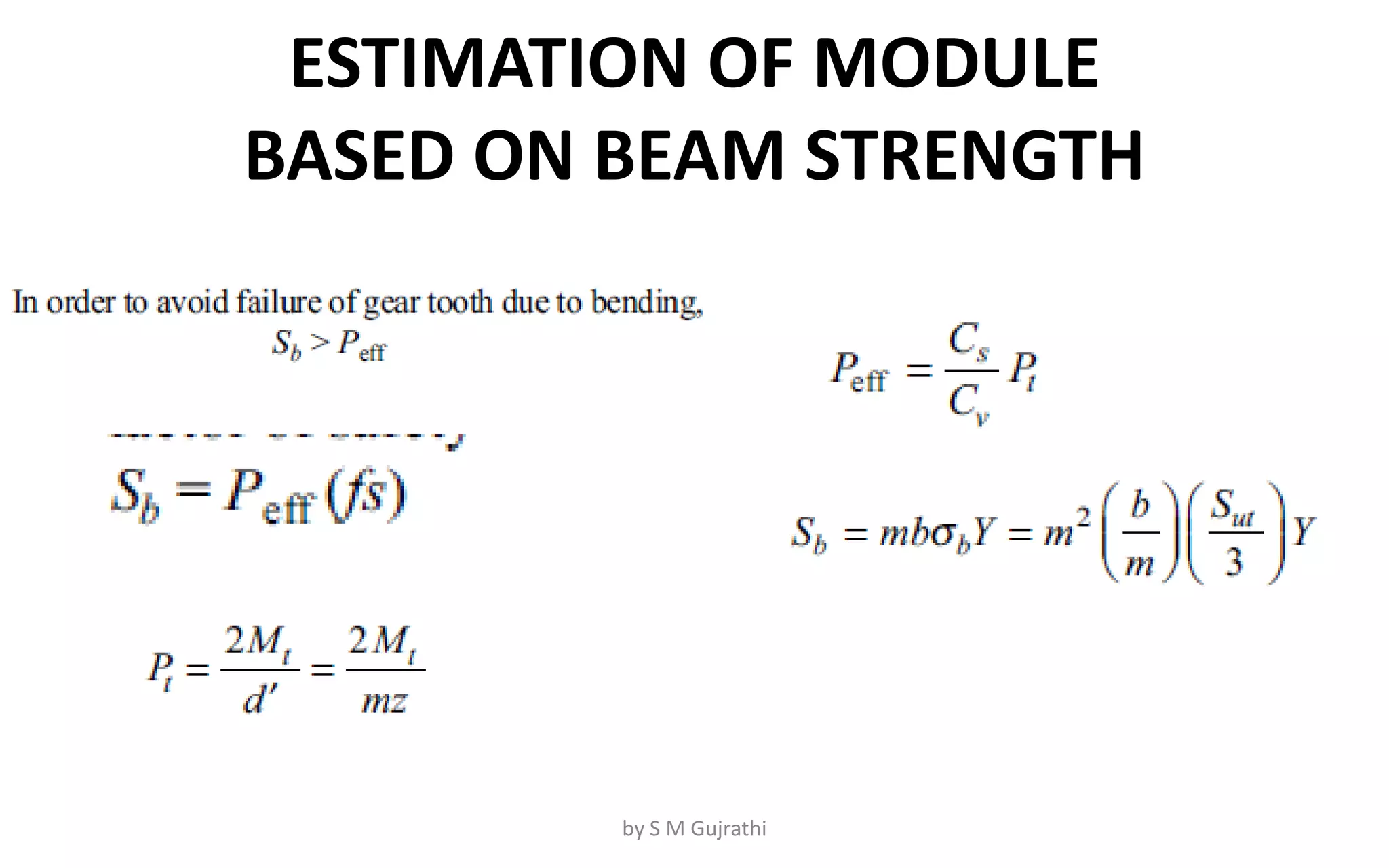

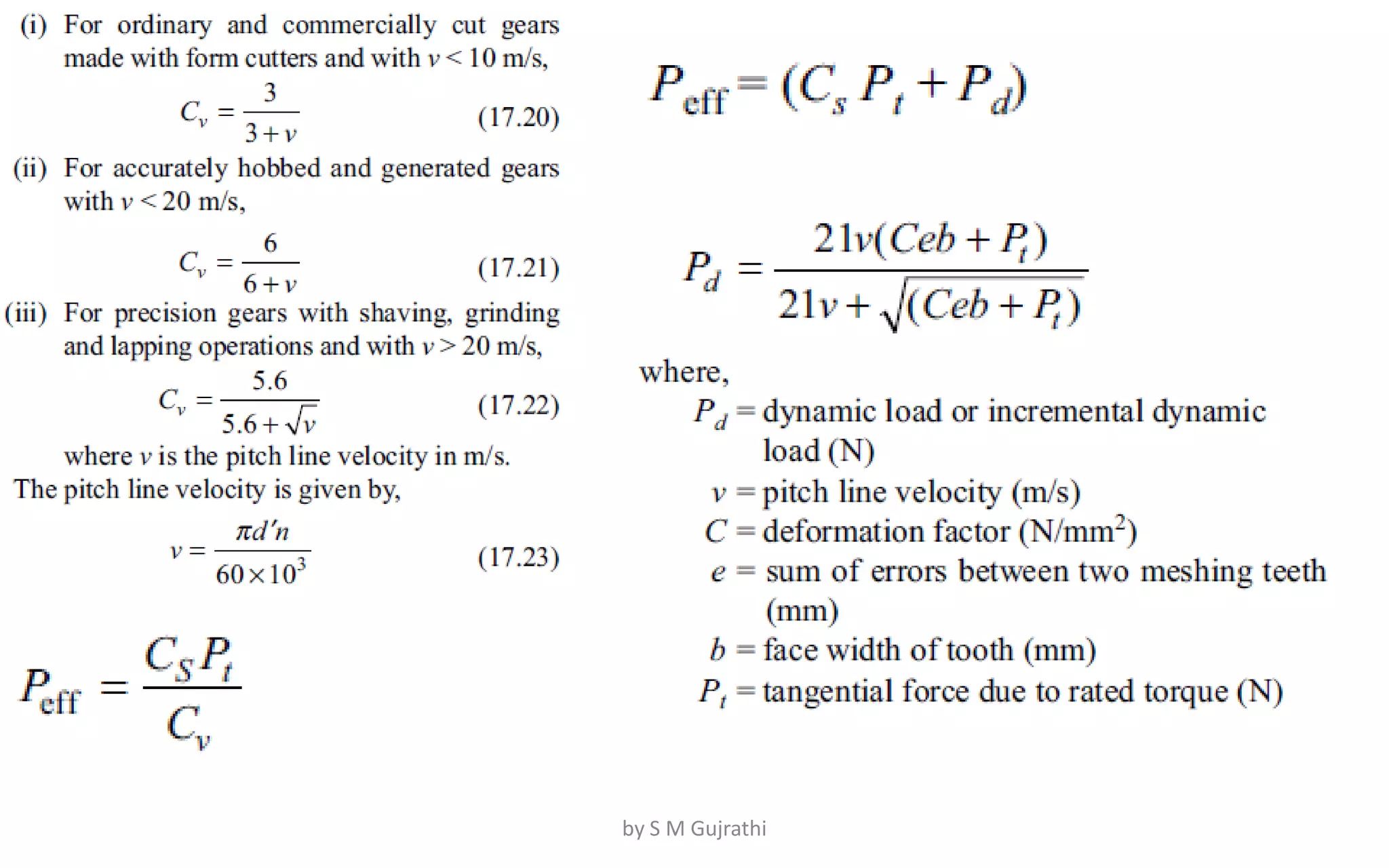

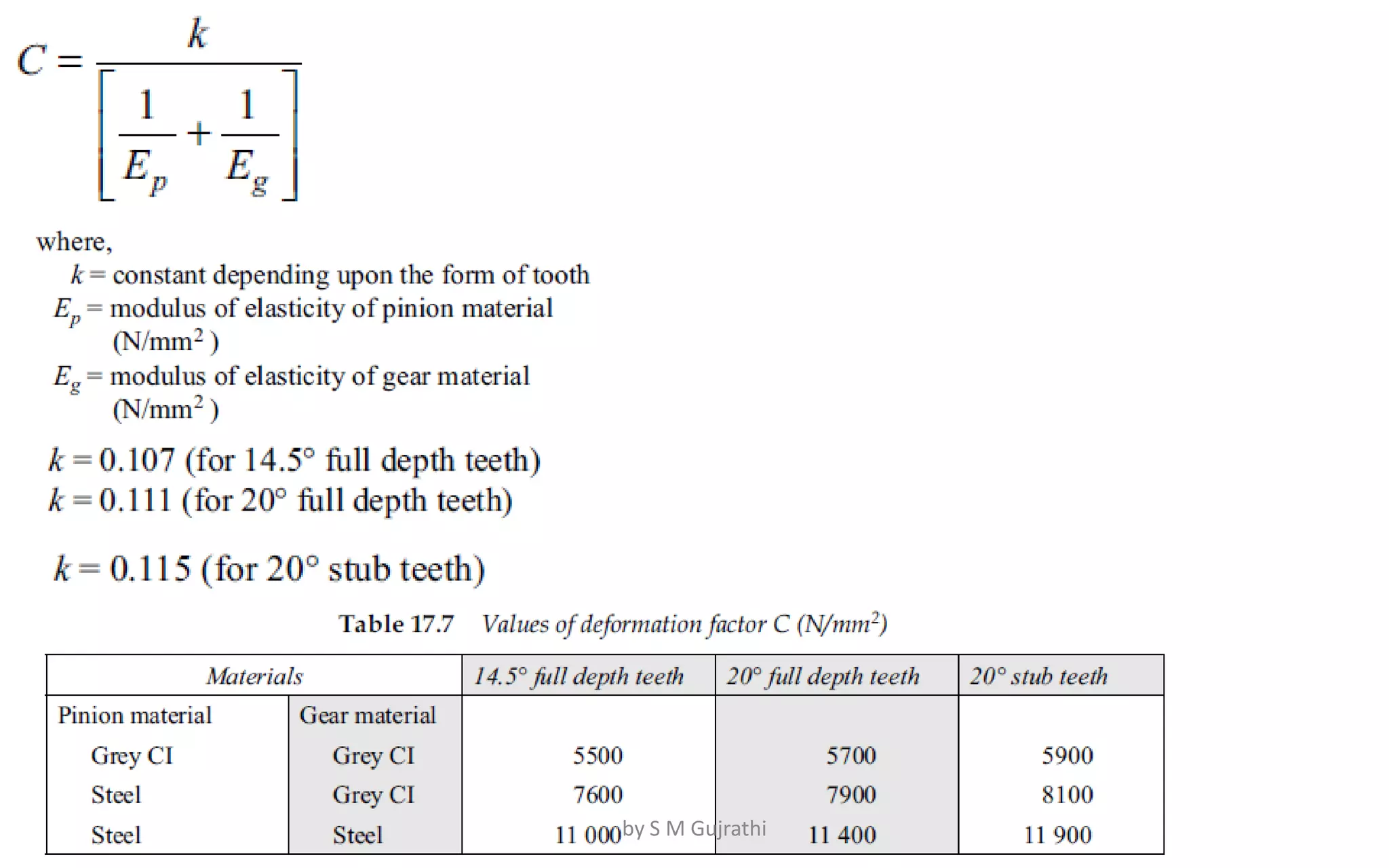

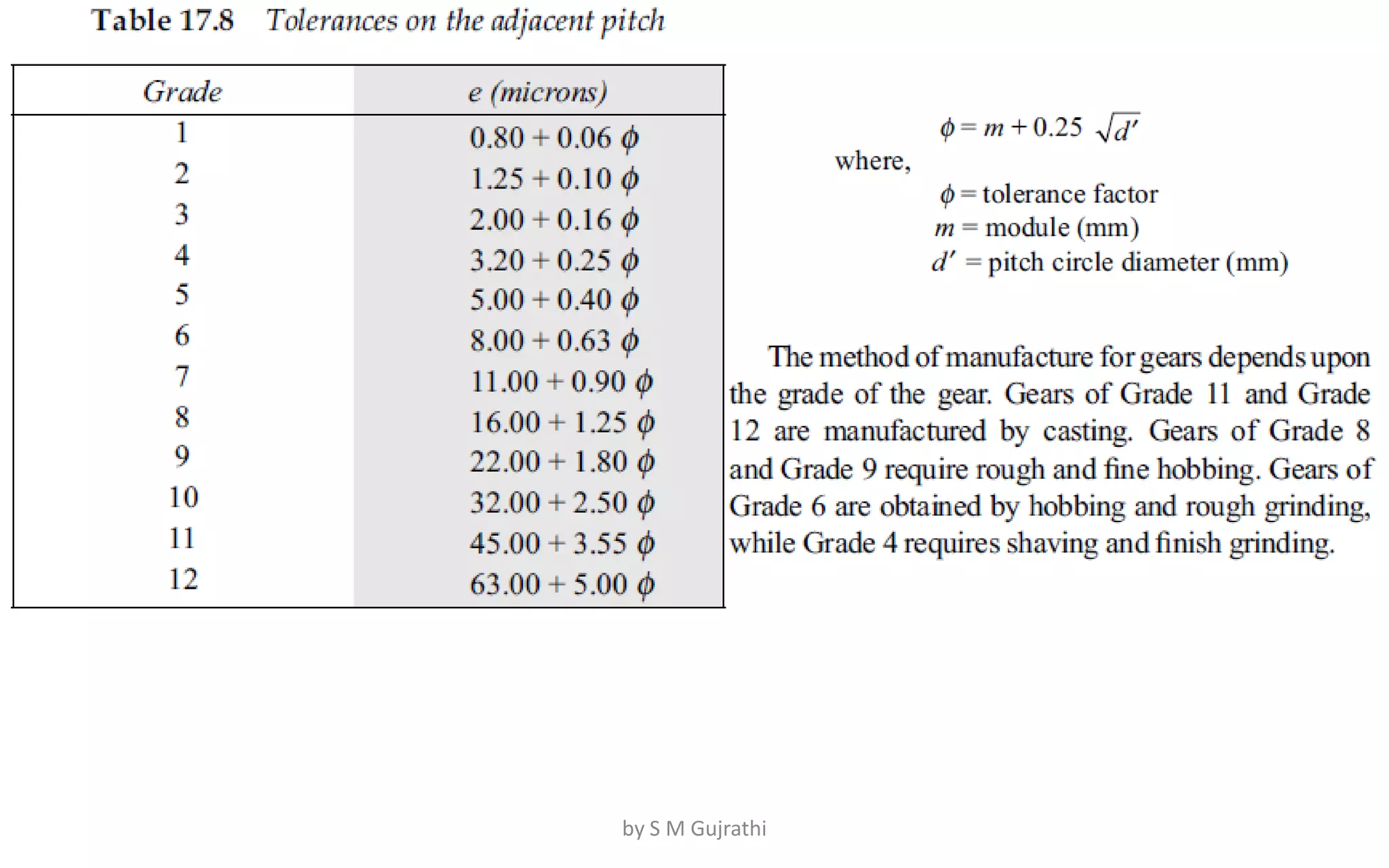

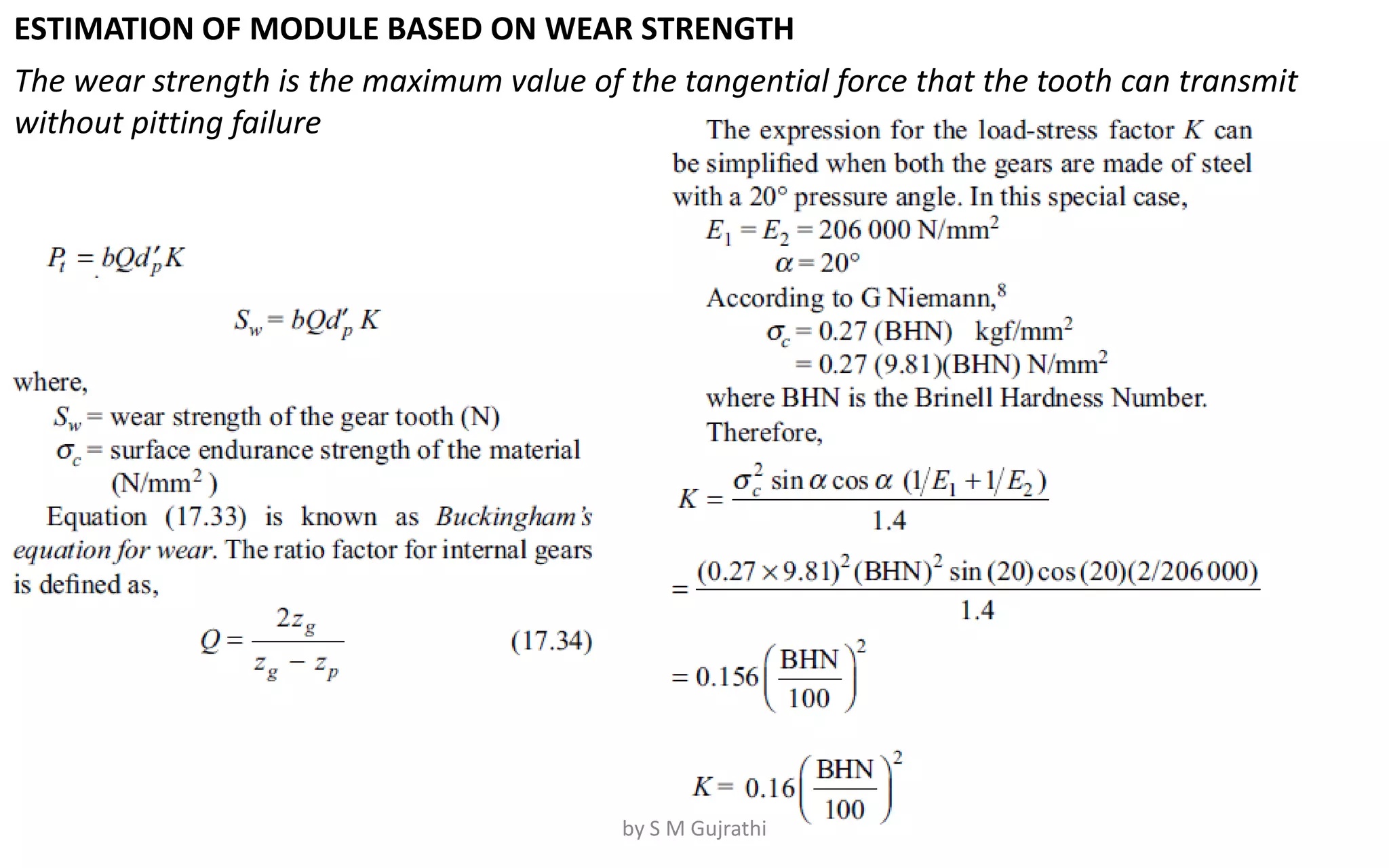

This document provides an introduction to Machine Design-II taught to third year mechanical engineering students. It covers the design of spur gears, including their selection, materials, failure modes, and lubrication methods. Specific topics on spur gears include number of teeth, force analysis, beam strength, velocity factors, loads, and equations for estimating module and dynamic tooth loads. Helical and bevel gears are also introduced, along with terminology, force analysis, design based on strength, loads, and mountings.