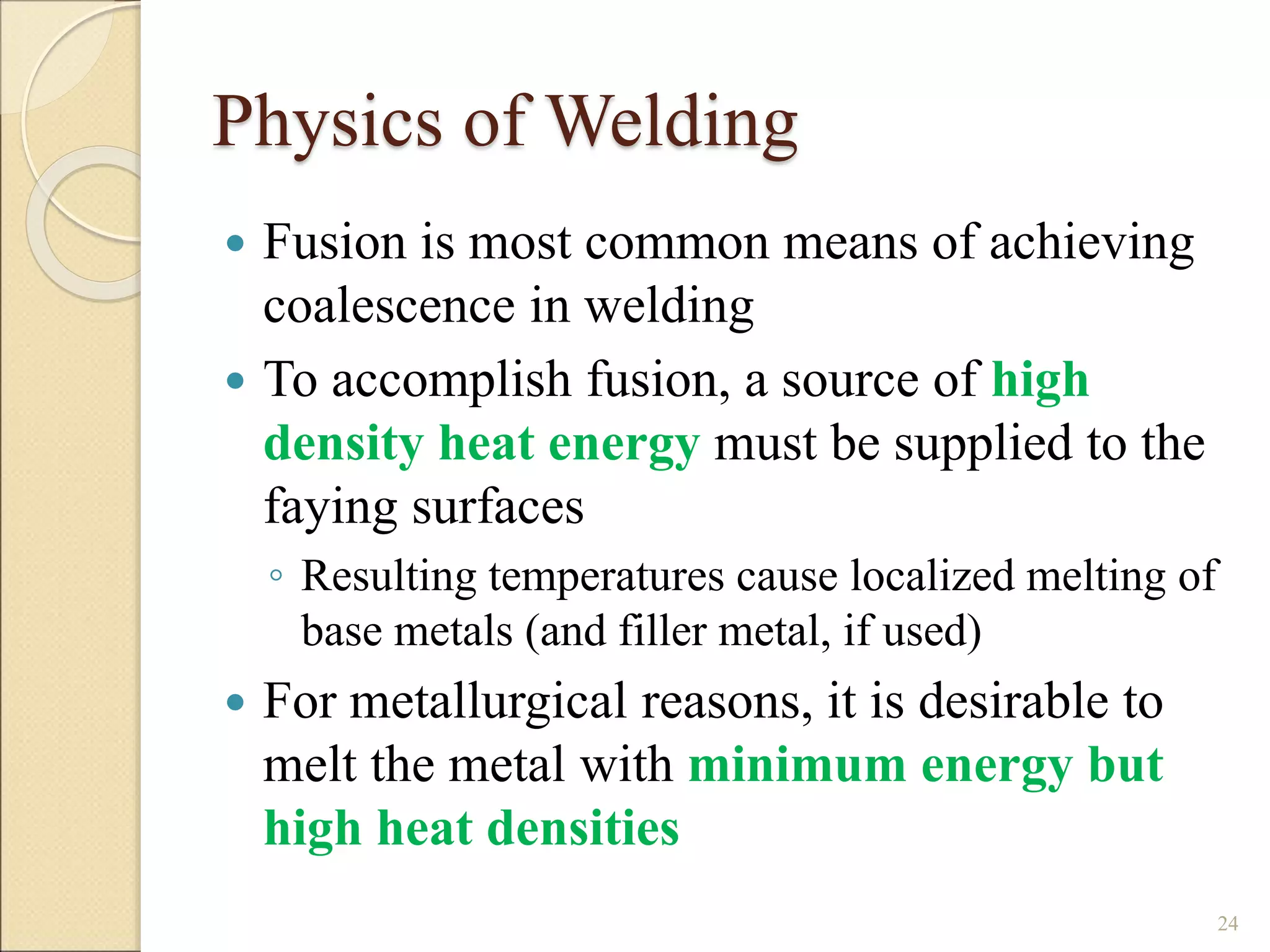

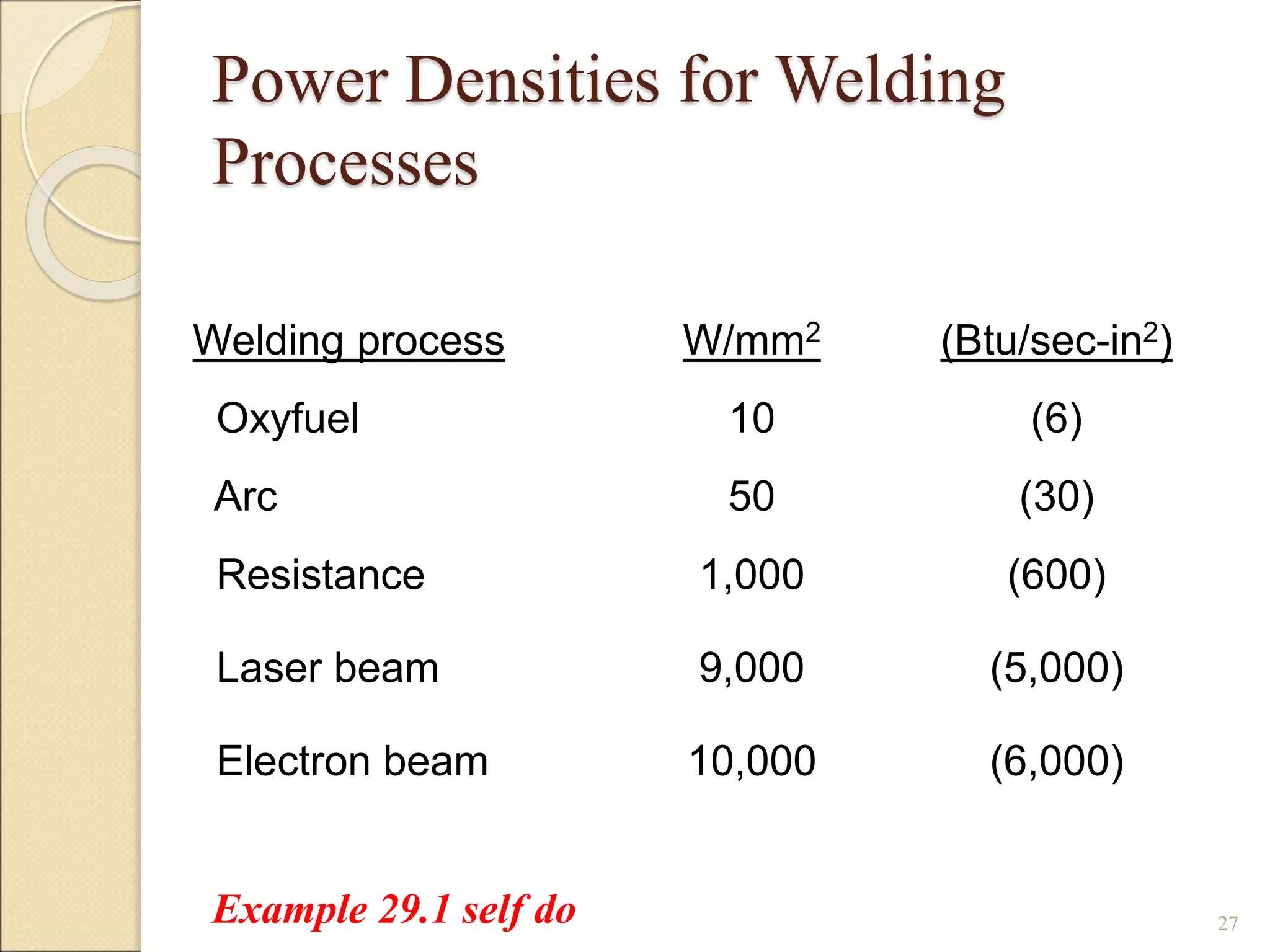

Welding is a process that joins materials by causing coalescence at their contacting surfaces through heating or pressure. There are many types of welding processes that are categorized as either fusion welding, which melts the materials, or solid state welding, which joins without melting. Key factors in welding include the joint design, type of weld, necessary heat transfer properties, and energy requirements for melting. Proper welding requires consideration of these fundamentals to produce high quality joints.