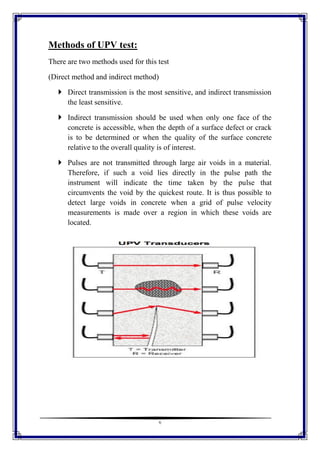

Ultrasonic pulse velocity (UPV) testing provides non-destructive evaluation of concrete by transmitting ultrasonic pulses through the material. The pulse velocity is dependent on concrete density and elastic properties, which relate to quality and compressive strength. UPV can detect voids, cracks, and defects by measuring the time it takes pulses to travel between transducers placed on the surface. Well-trained operators using modern UPV equipment can reliably examine concrete interior and determine properties like uniformity, cracking, strength, layer thickness, and elastic modulus. However, UPV has limitations and cannot replace destructive testing.