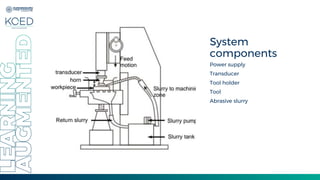

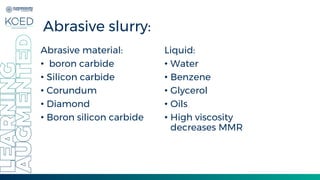

Ultrasonic machining uses high frequency vibrations and an abrasive slurry to erode small holes and cavities in hard materials. It works by applying pressure between an oscillating tool and the workpiece in the presence of abrasive particles. Key components include a power supply, transducer, tool holder and abrasive slurry. The slurry typically contains boron carbide or silicon carbide abrasives in a liquid like water or oil. Ultrasonic machining can precisely machine brittle materials without causing thermal or chemical damage thanks to its non-thermal nature.