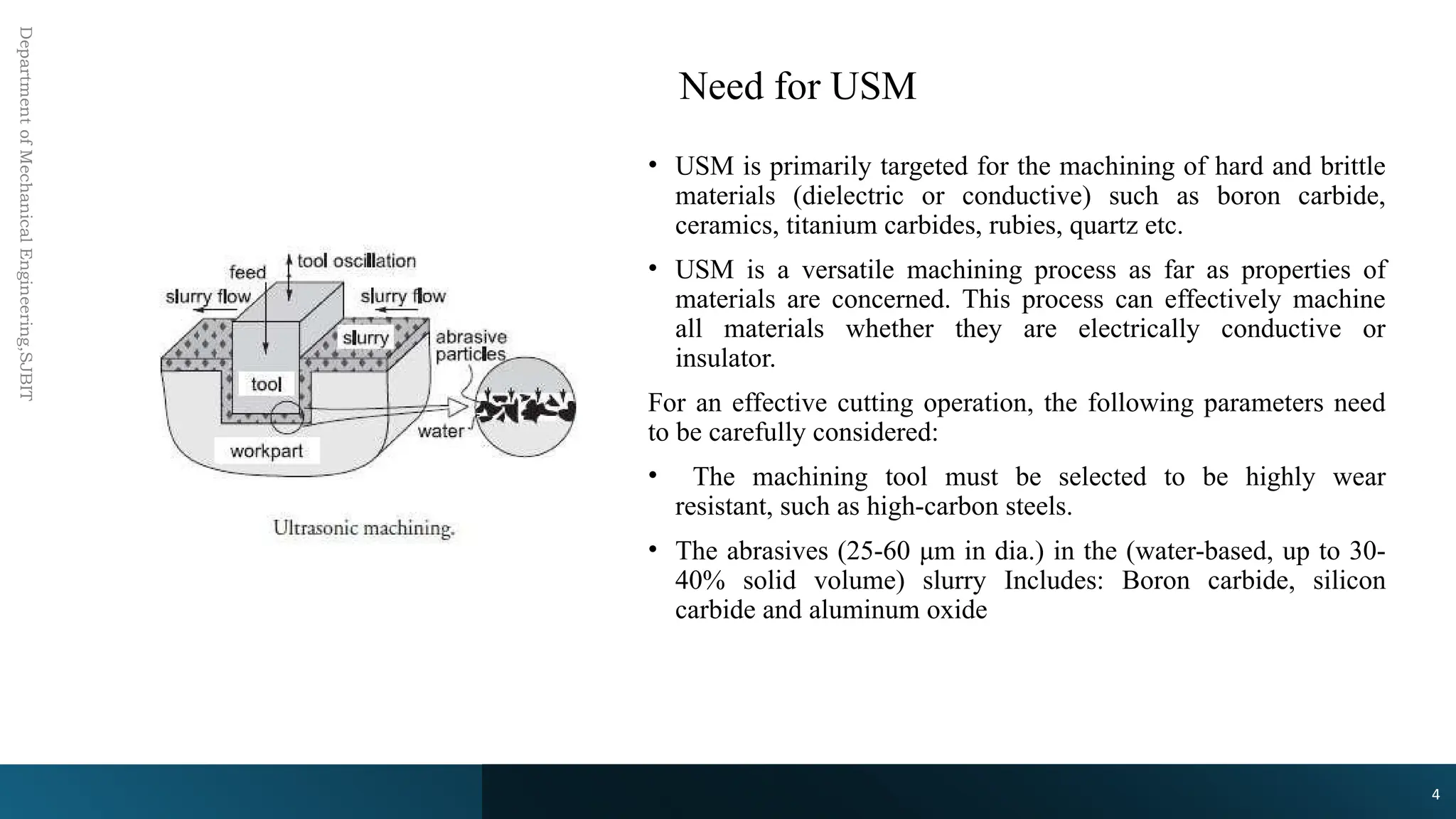

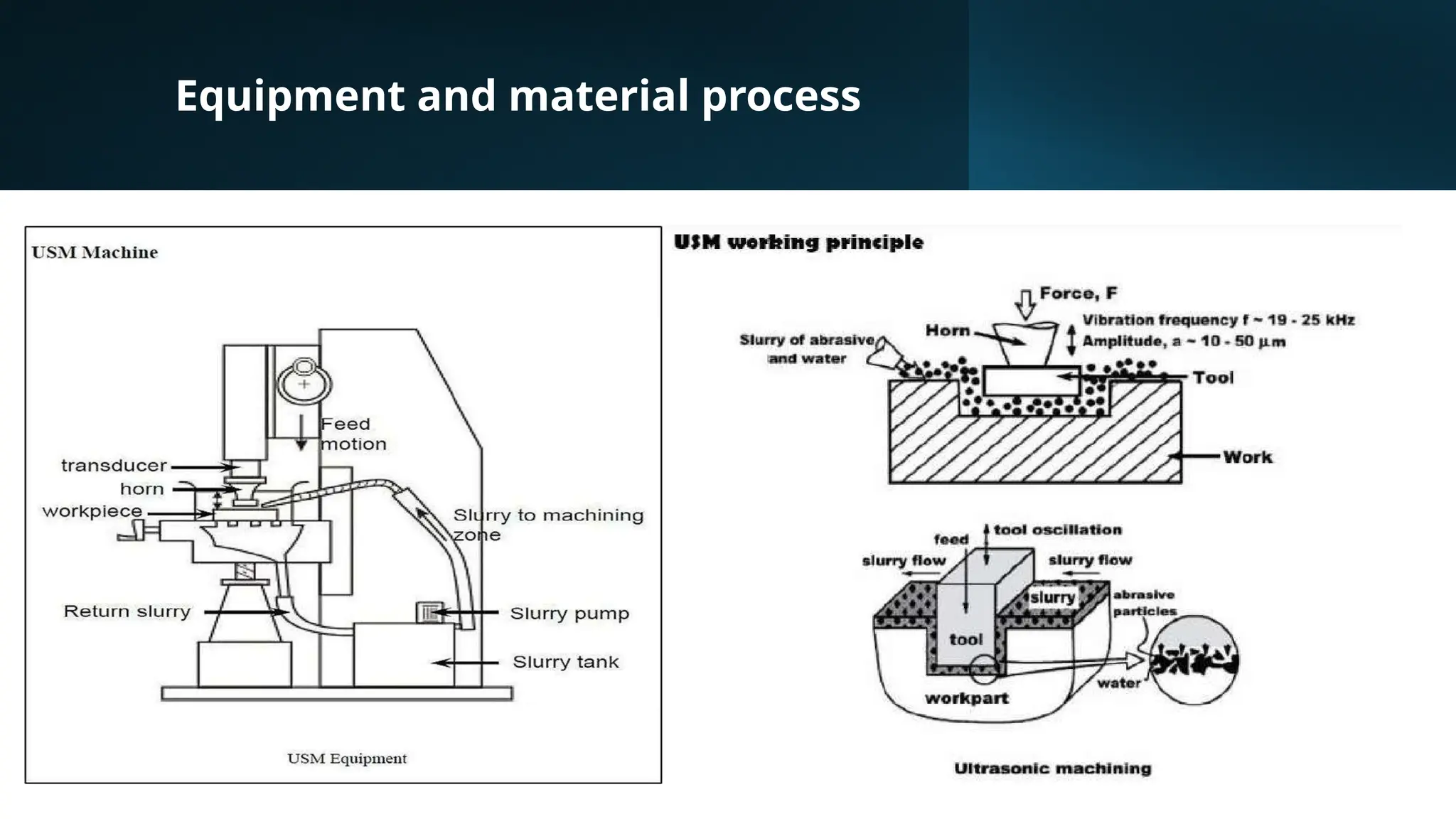

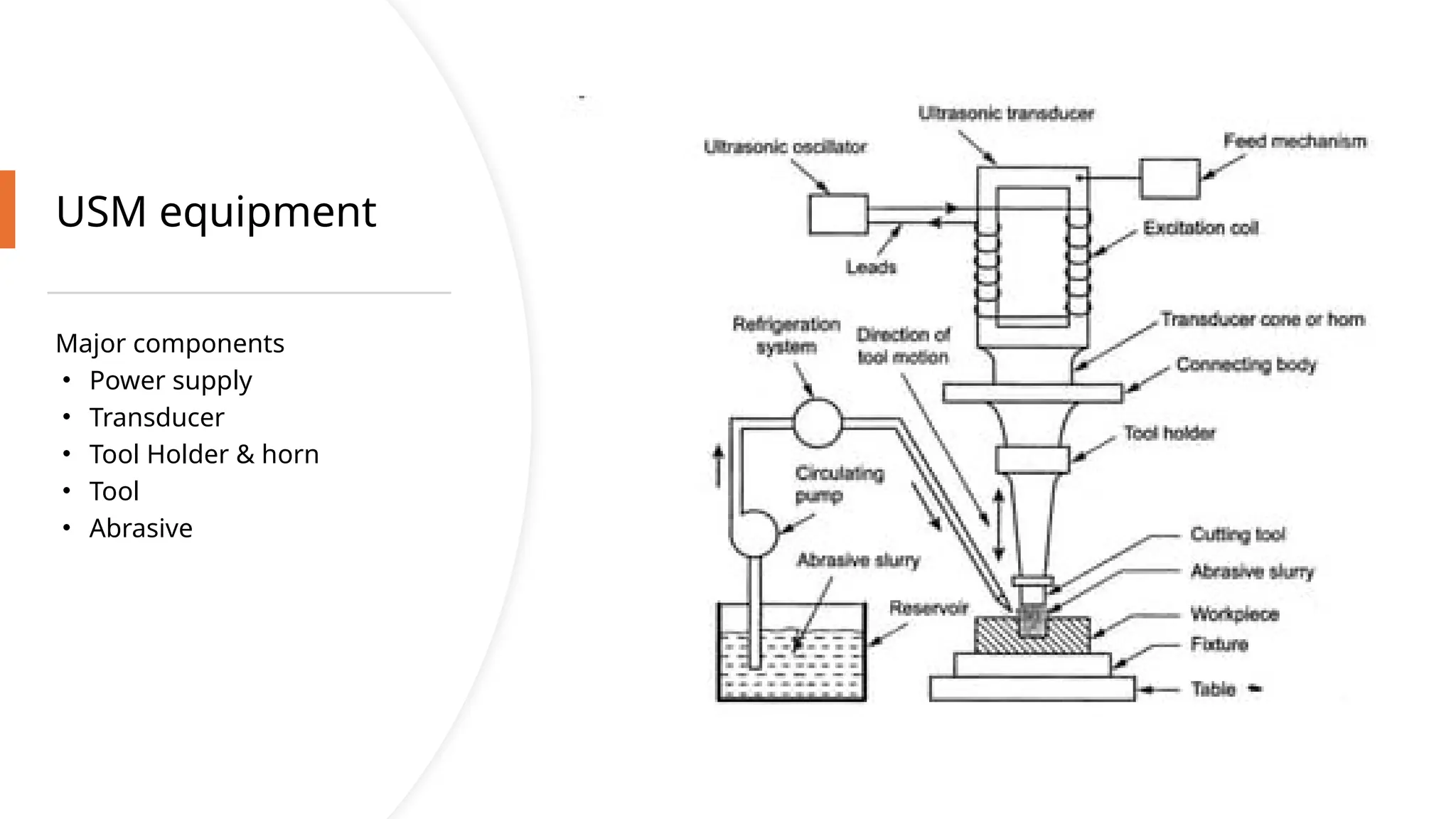

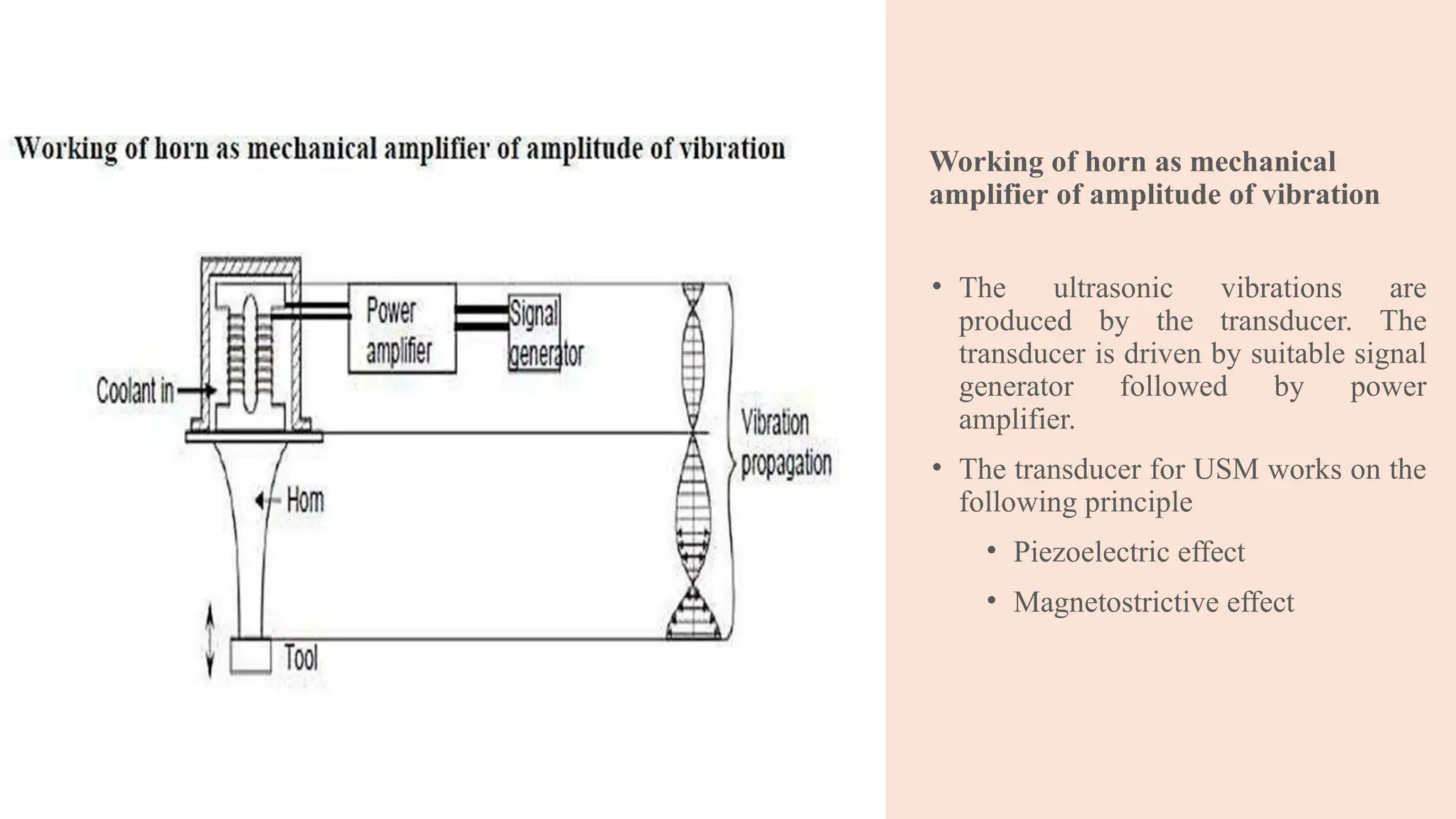

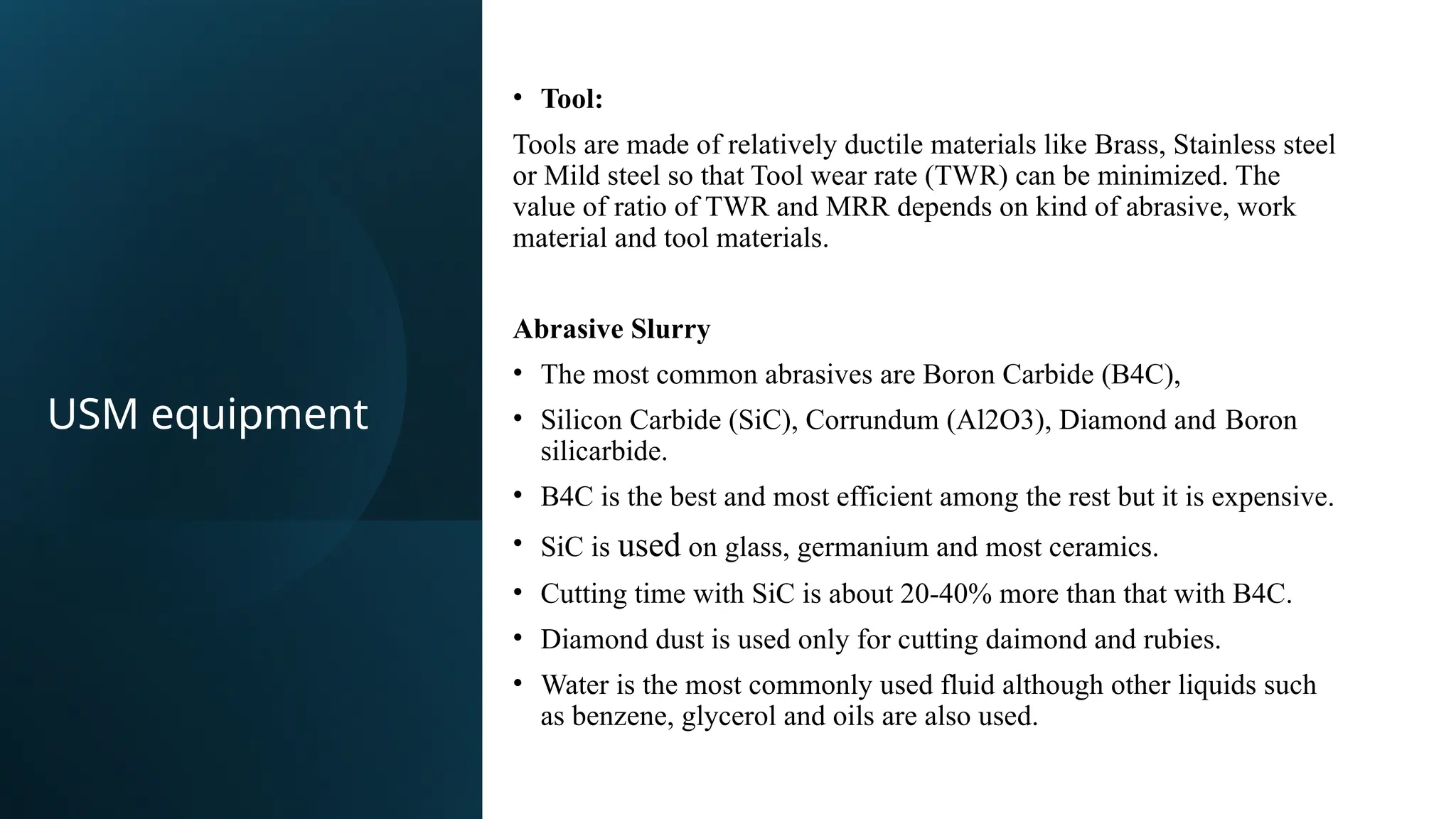

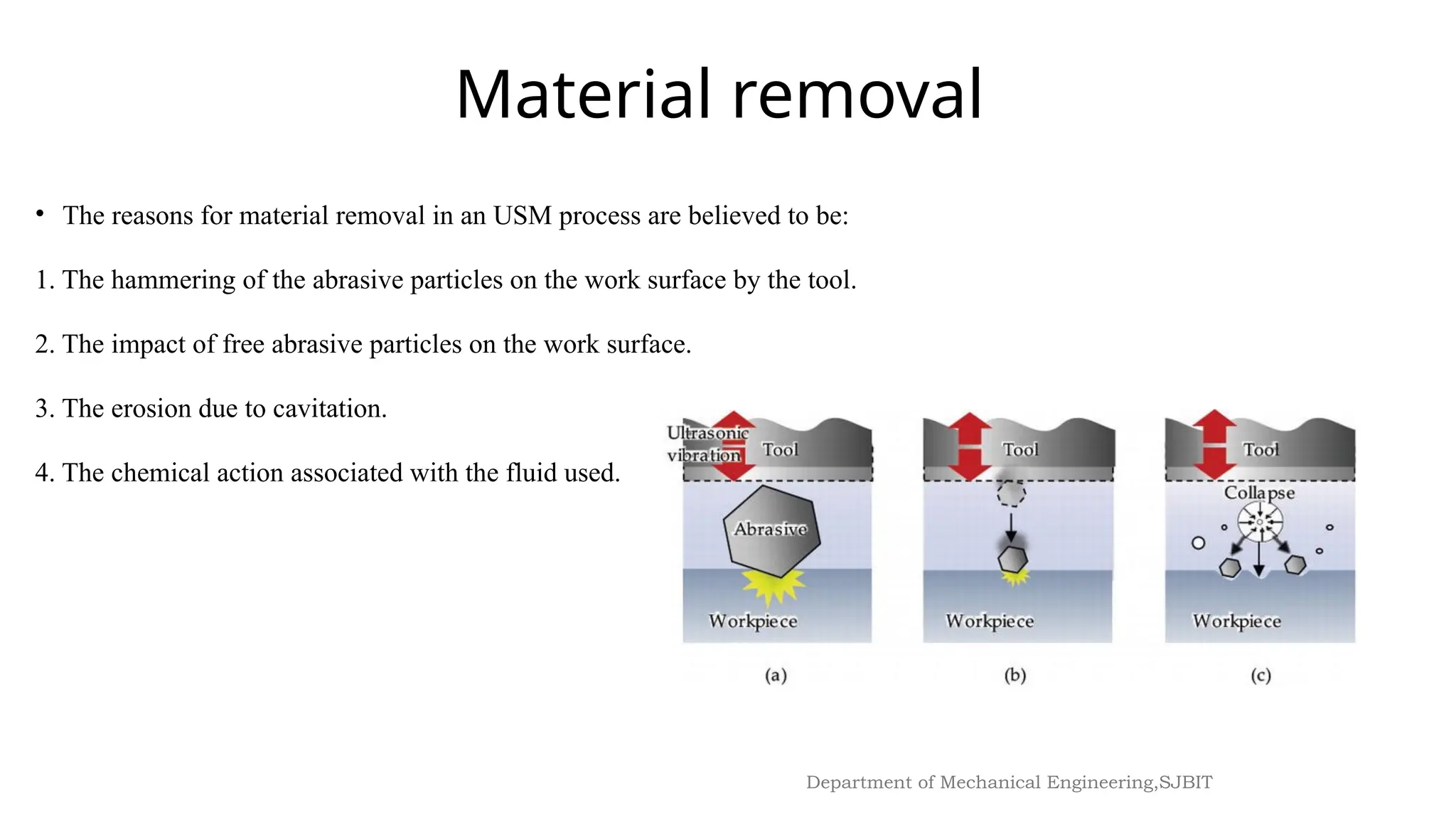

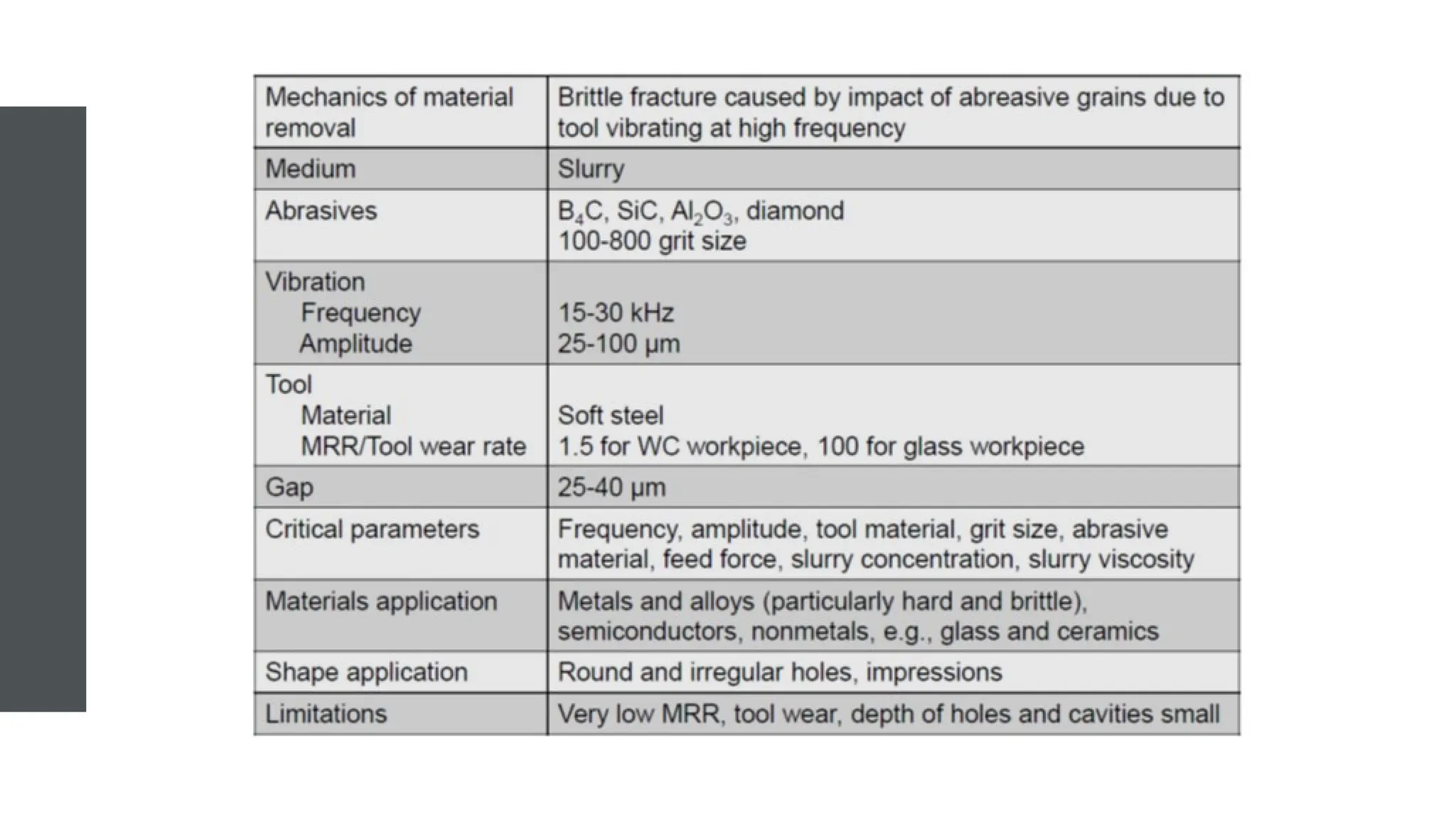

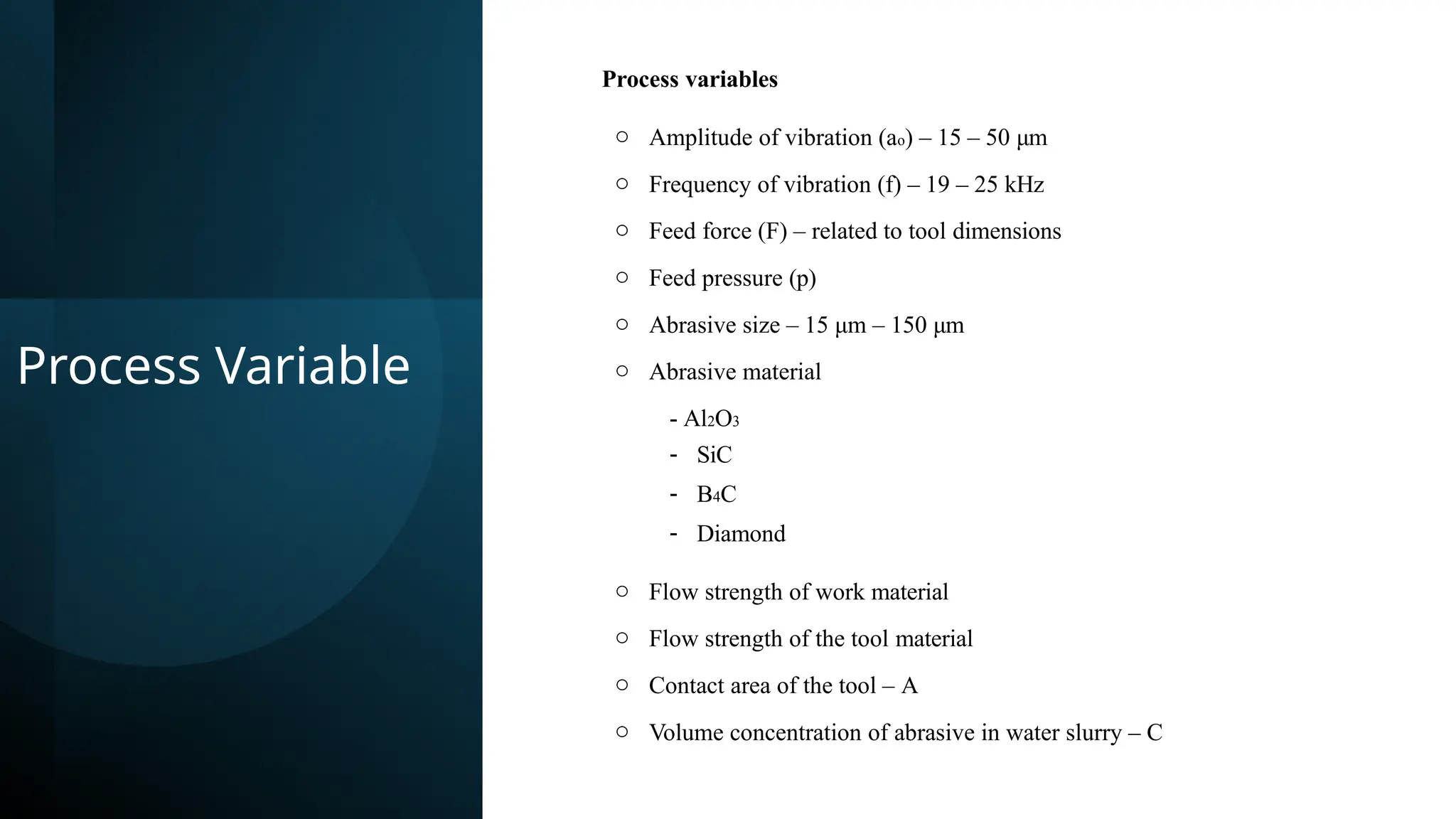

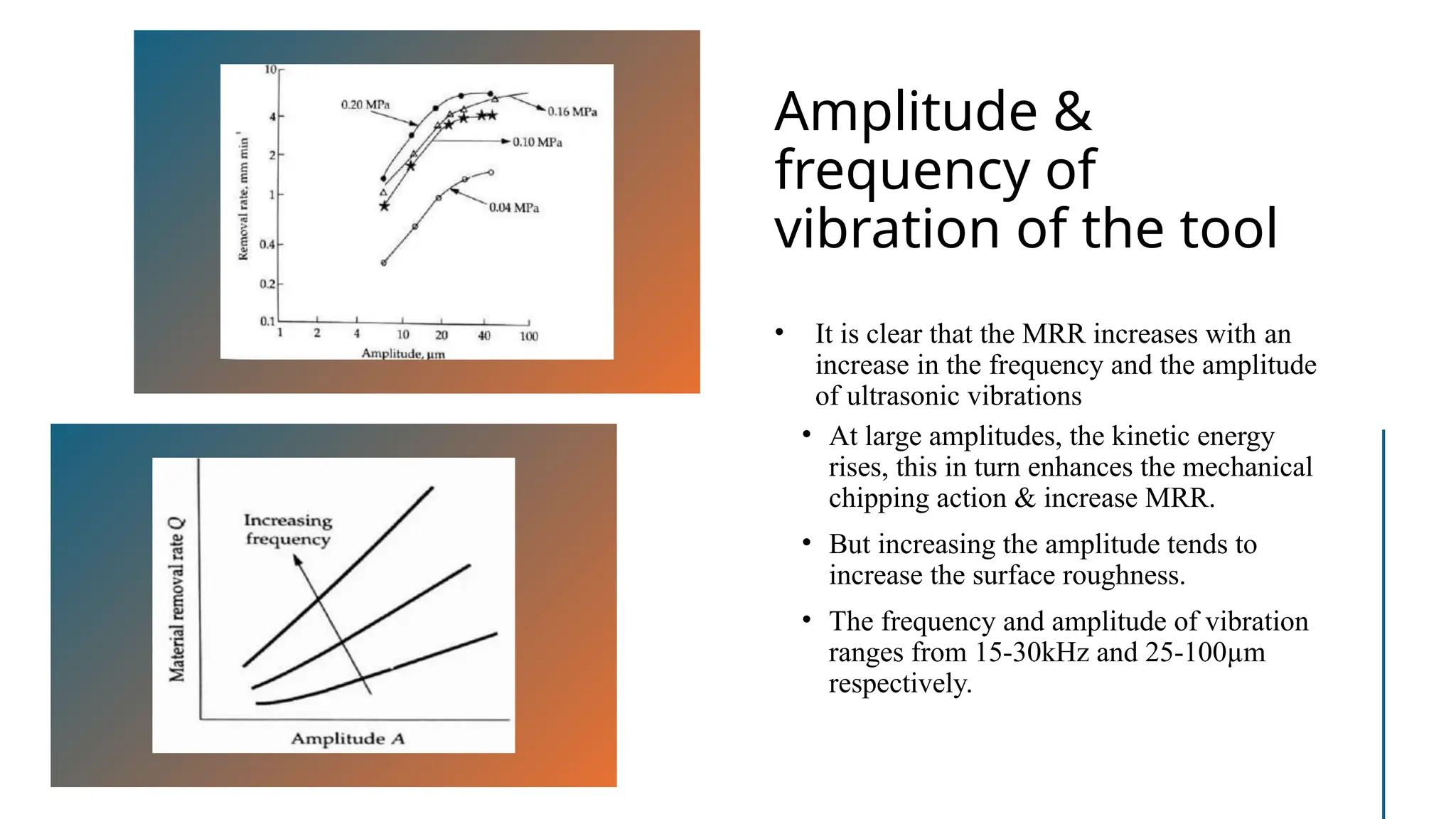

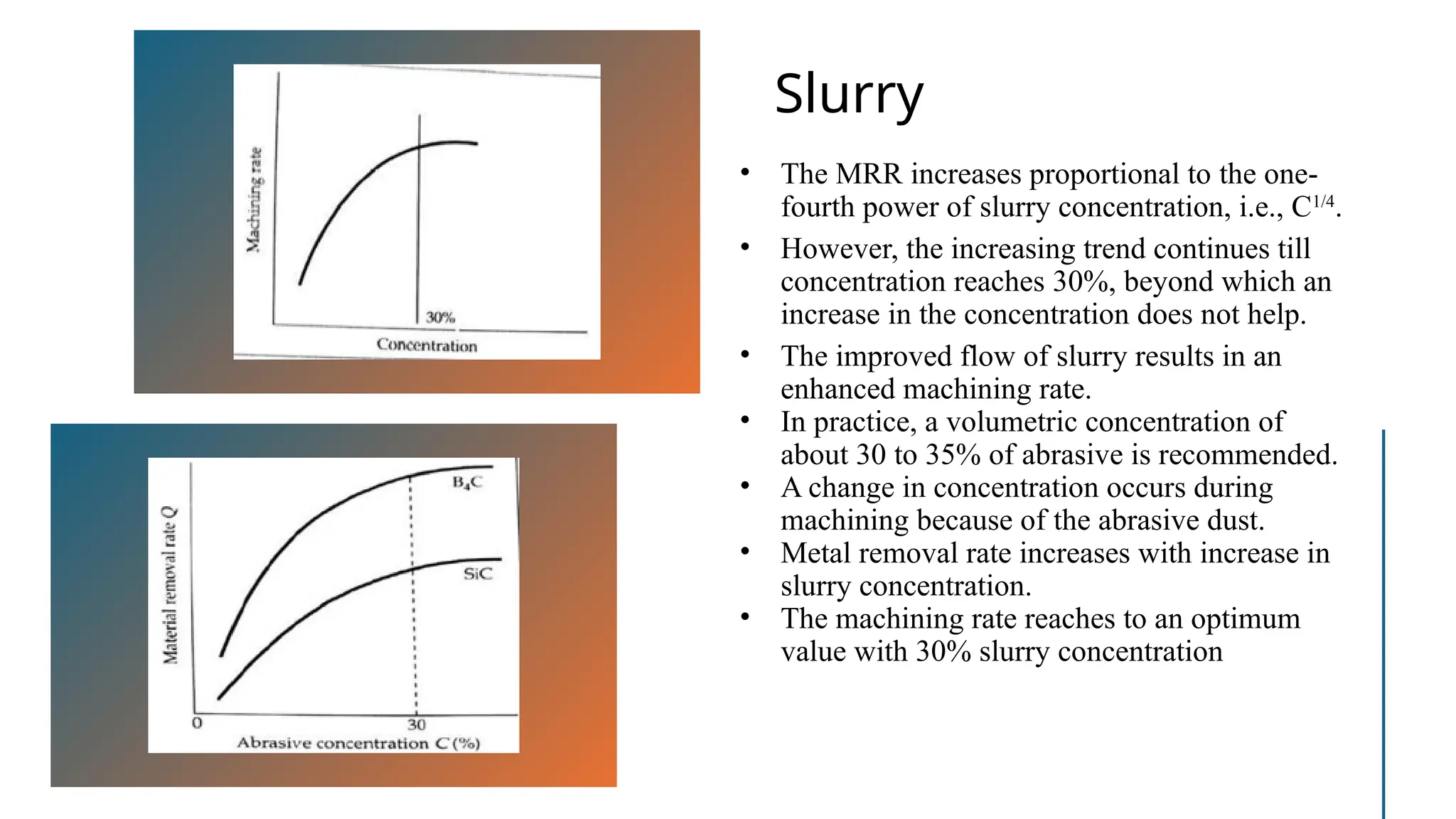

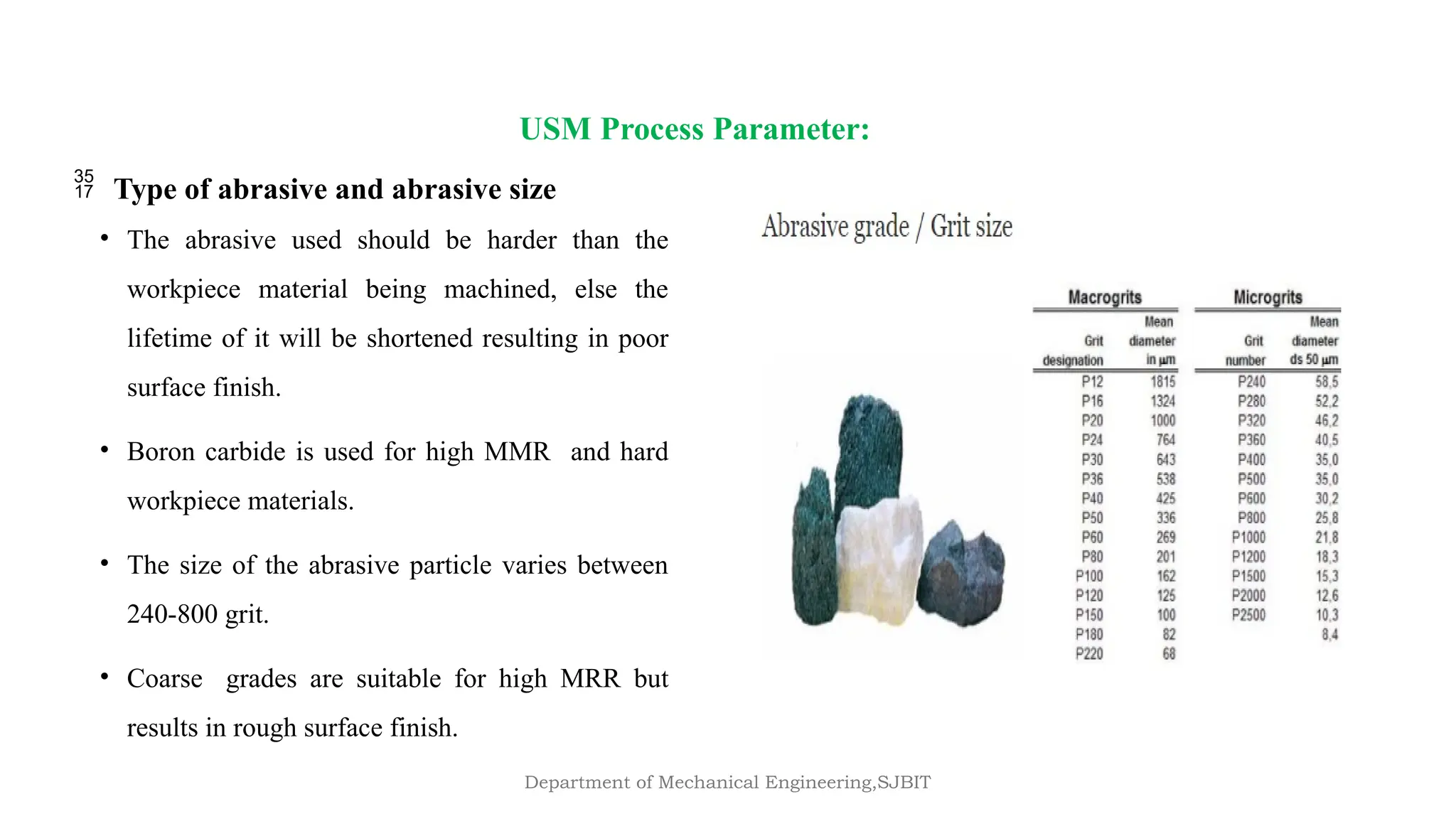

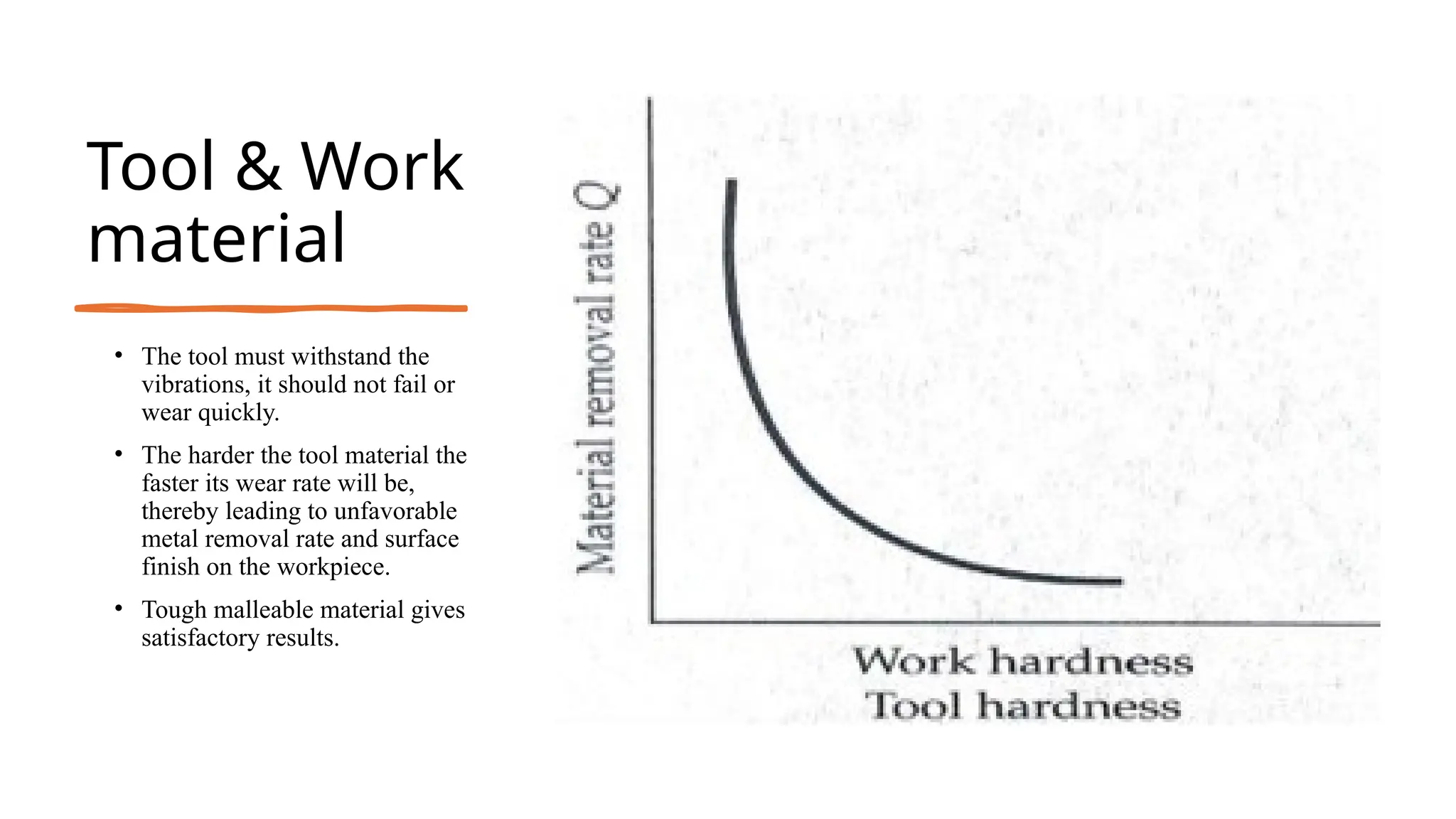

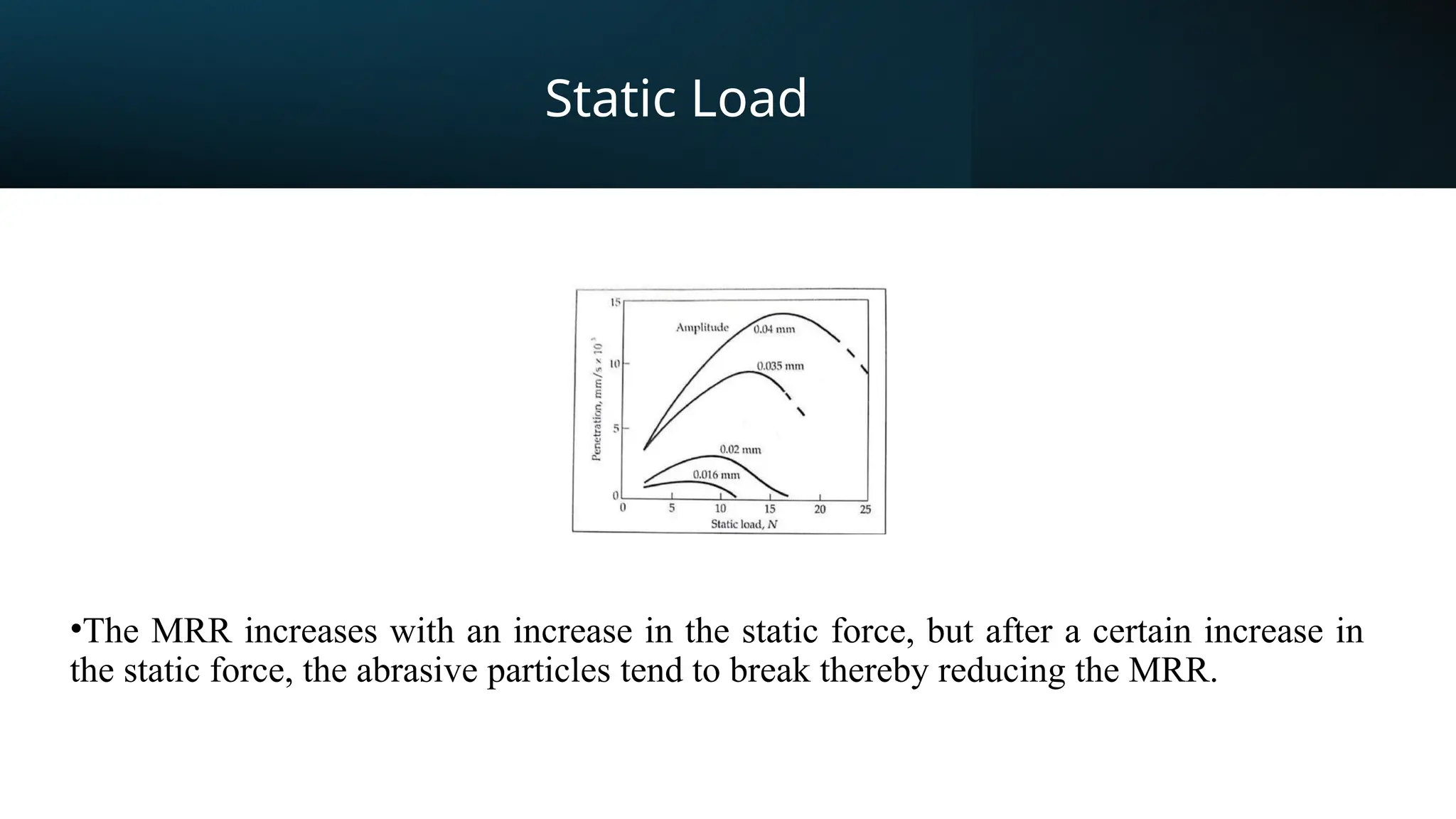

Ultrasonic machining (USM) is a non-traditional mechanical material removal process that erodes hard or brittle materials using high-frequency vibrations and an abrasive slurry. It is effective for a variety of materials, including ceramics, boron carbide, and titanium carbides, but has limitations such as faster tool wear and confinement of machining area and depth. USM offers advantages like better surface finish and structural integrity, making it suitable for intricate machining tasks, although it struggles with softer materials and incurs higher energy consumption compared to traditional methods.