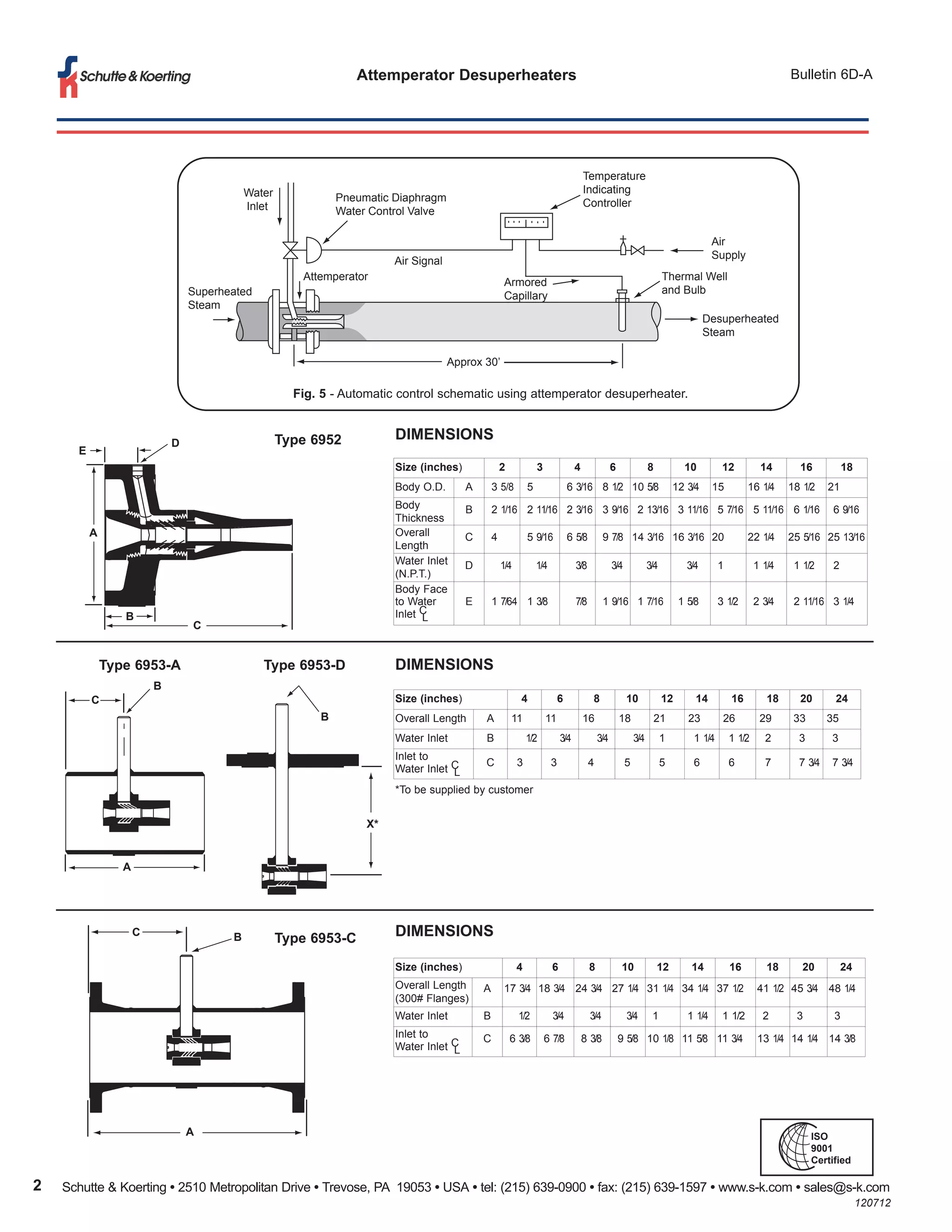

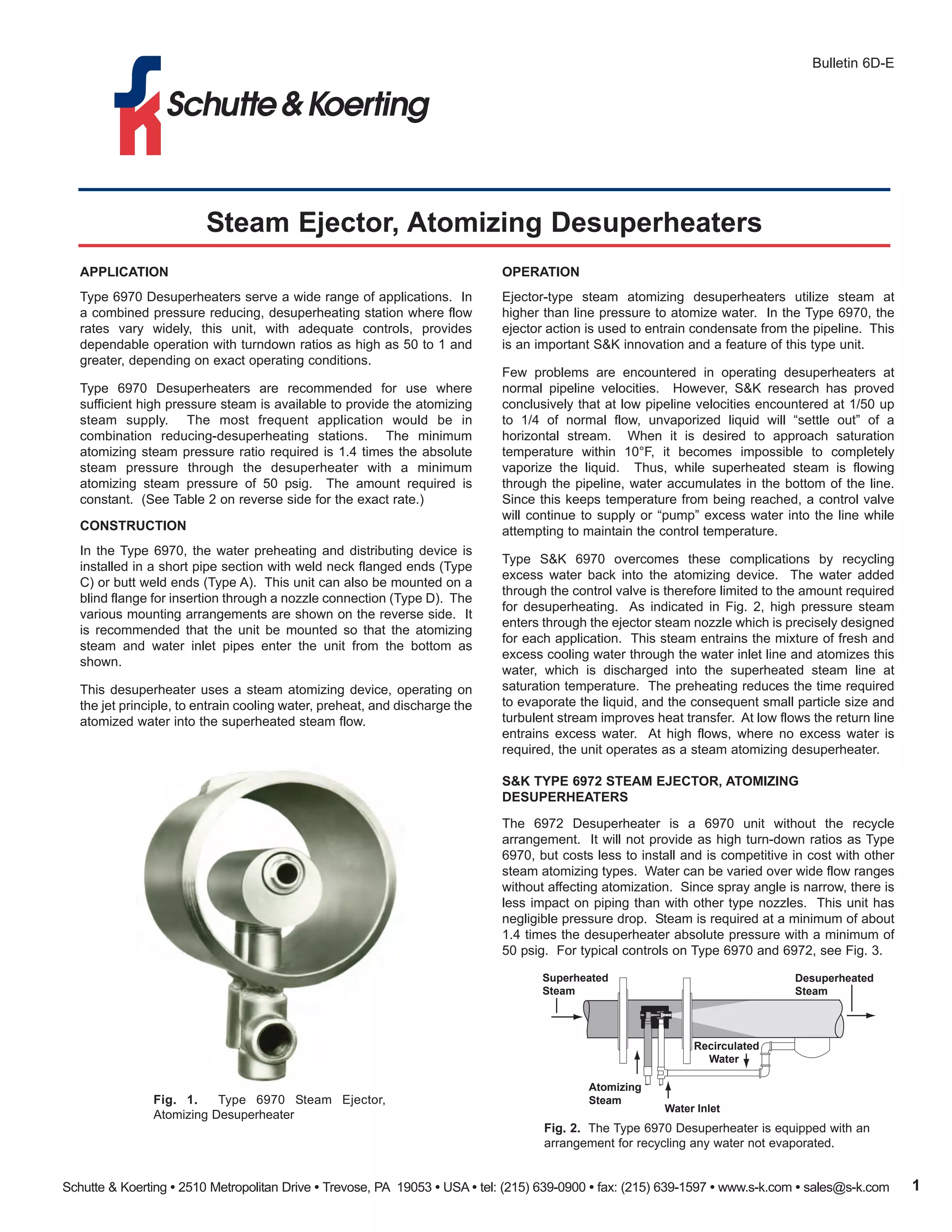

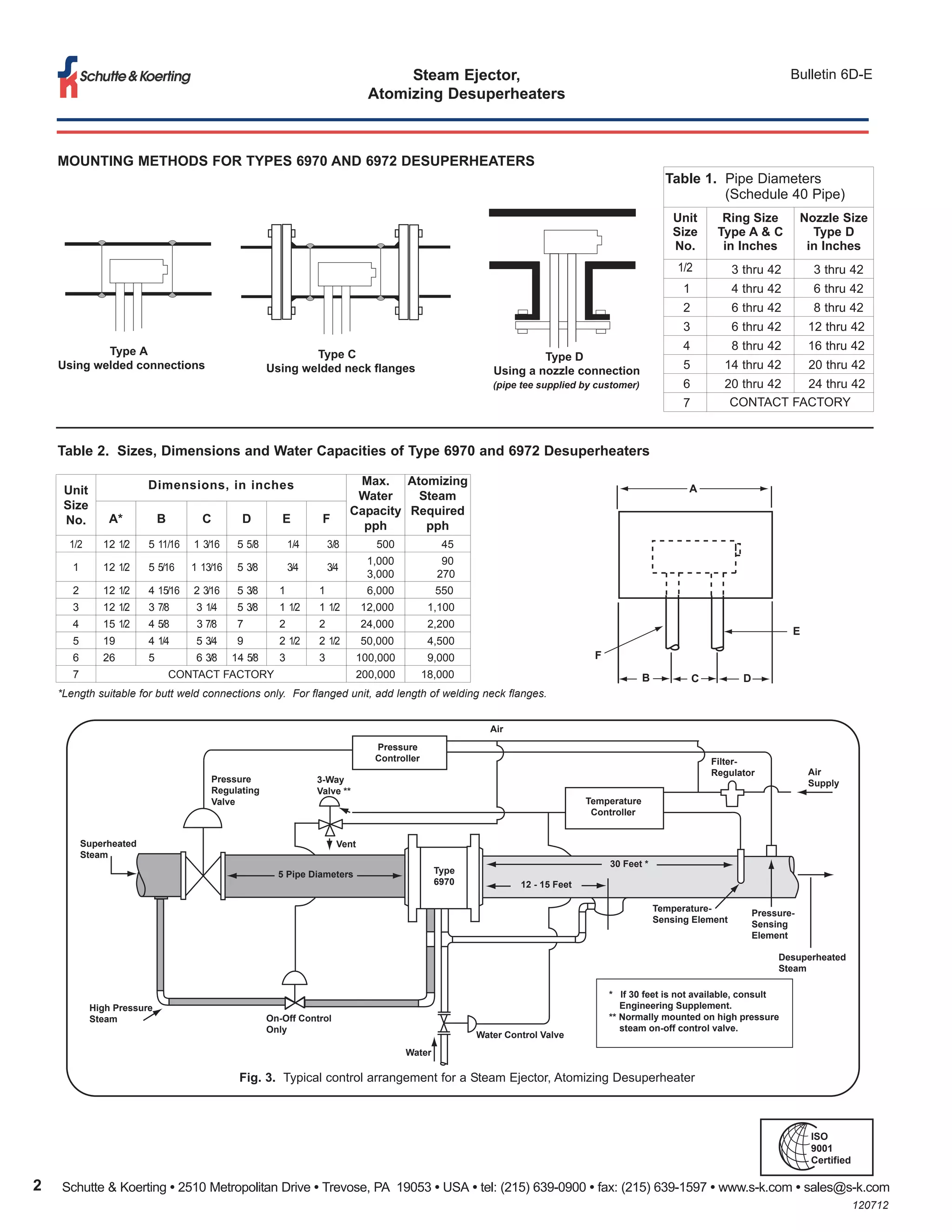

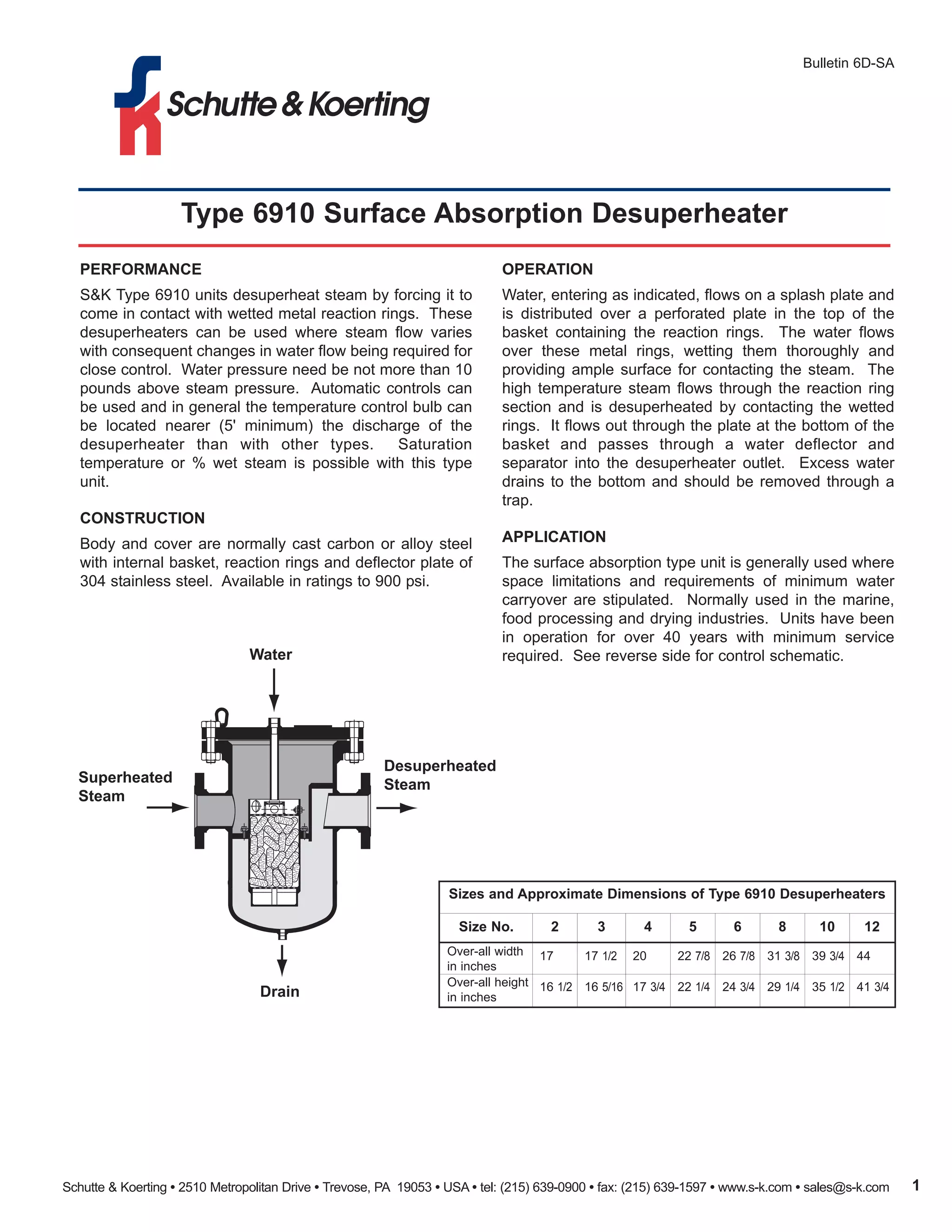

Schutte & Koerting's steam desuperheaters, introduced since 1923, are designed to reduce the temperature of superheated steam for various applications such as power plants and heat exchangers. They utilize different technologies, including mechanical spray and annular venturi designs, to atomize water and achieve efficient cooling without the need for high-pressure steam. The units are constructed from various metals and subjected to rigorous quality controls, making them suitable for diverse operational requirements.