The document discusses rotary regenerative air preheaters used in power plant boilers. It describes the components, construction, operation, maintenance checks, and safety devices of these air preheaters. The key points are:

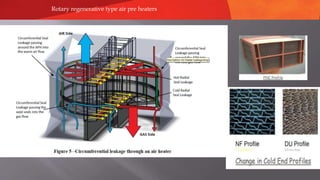

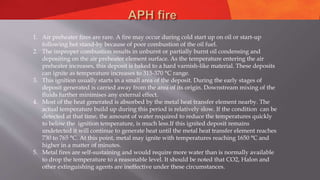

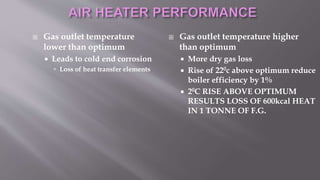

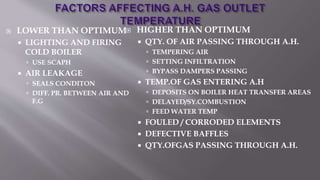

1) Rotary regenerative air preheaters recover waste heat from boiler flue gases to preheat combustion air, improving boiler efficiency. They contain a rotating matrix that alternately passes through gas and air passages to transfer heat.

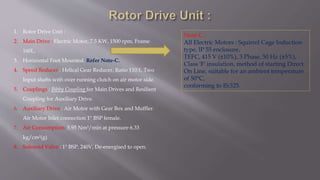

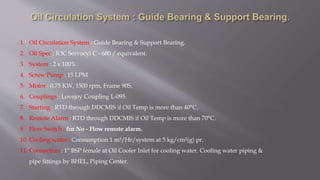

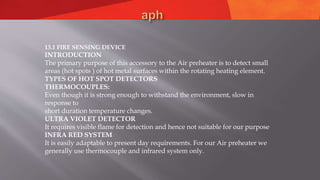

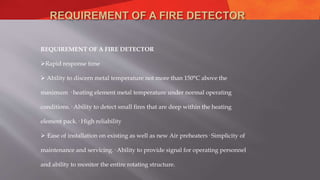

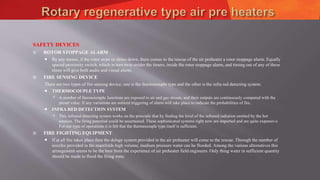

2) Components include a rotor, bearings, housing, connecting plates, seals, and a drive unit. Safety devices detect fires and overheating using thermocouples or infrared sensors.

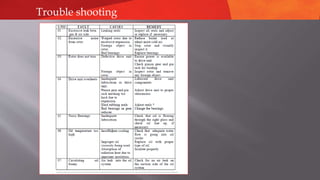

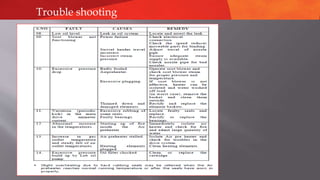

3) Regular maintenance checks include inspecting oil levels,