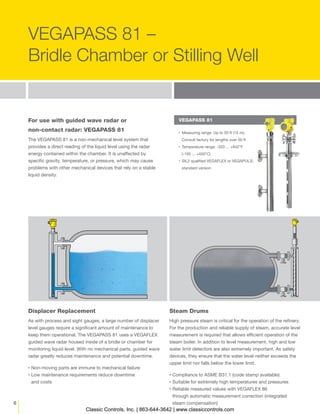

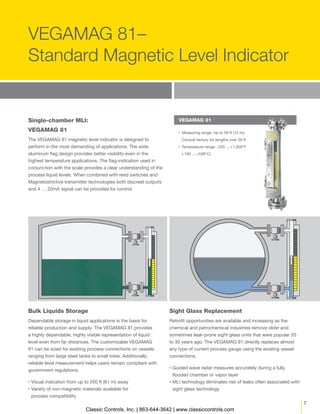

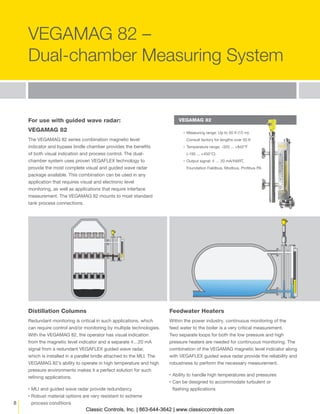

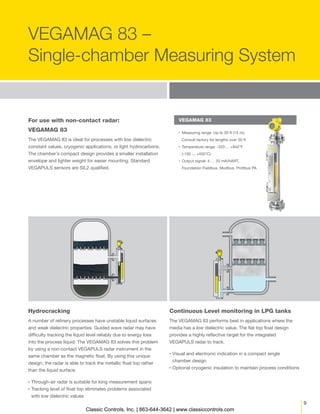

The document provides an overview of magnetic level indicators and bridles for continuous level and interface measurement, emphasizing Vega's commitment to reliable solutions across various challenging applications. It details the features and benefits of multiple products, including the Vegamag and Vegapass series, which utilize advanced radar technology for accurate level measurement while minimizing maintenance needs. Vega also offers a performance guarantee, extensive field service support, and customization options to meet specific industry requirements.