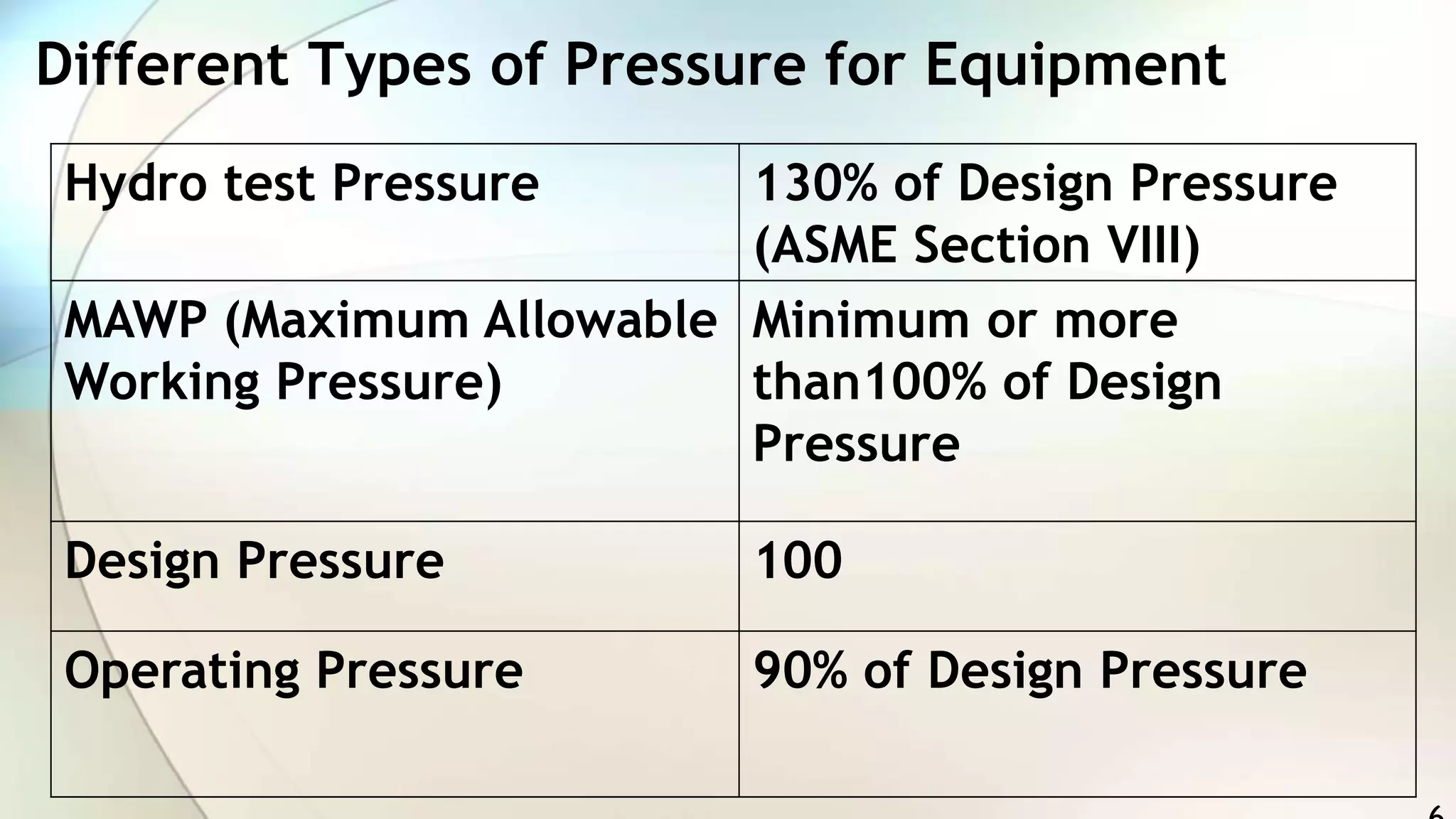

The document discusses various pressure concepts related to equipment design, including operating pressure, design pressure, and maximum allowable working pressure (MAWP). It outlines the relationship between these pressures and how manufacturers determine equipment thickness for safety, based on standards such as ASME Section VIII. Additionally, it mentions testing pressures for hydro and pneumatic tests in accordance with design pressures.