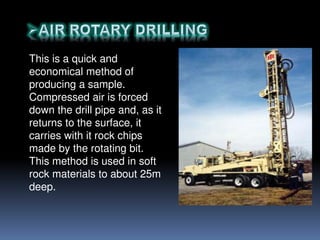

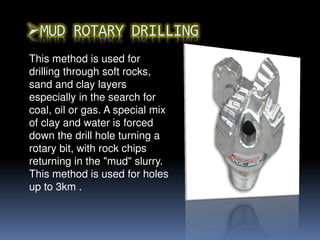

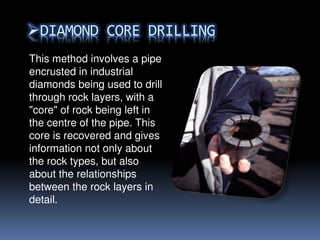

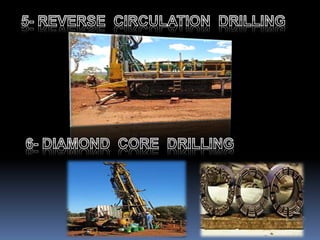

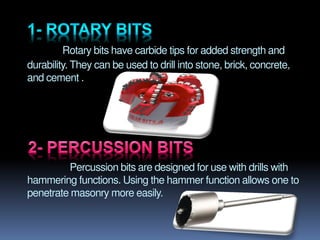

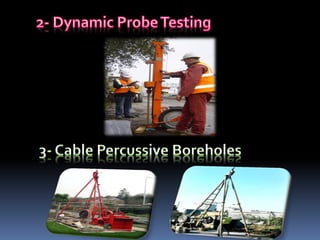

The document outlines the history of oil drilling, starting from ancient techniques in China to modern methods. It describes four primary drilling techniques: air rotary, air percussion, mud rotary, and diamond core drilling, each suited for different rock types and depths. The document also mentions various drill bit types for different materials and emphasizes the importance of site investigations for assessing soil conditions and ensuring project suitability.