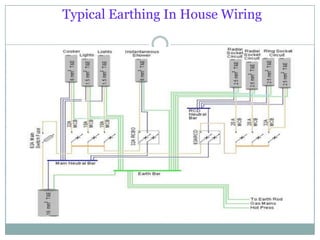

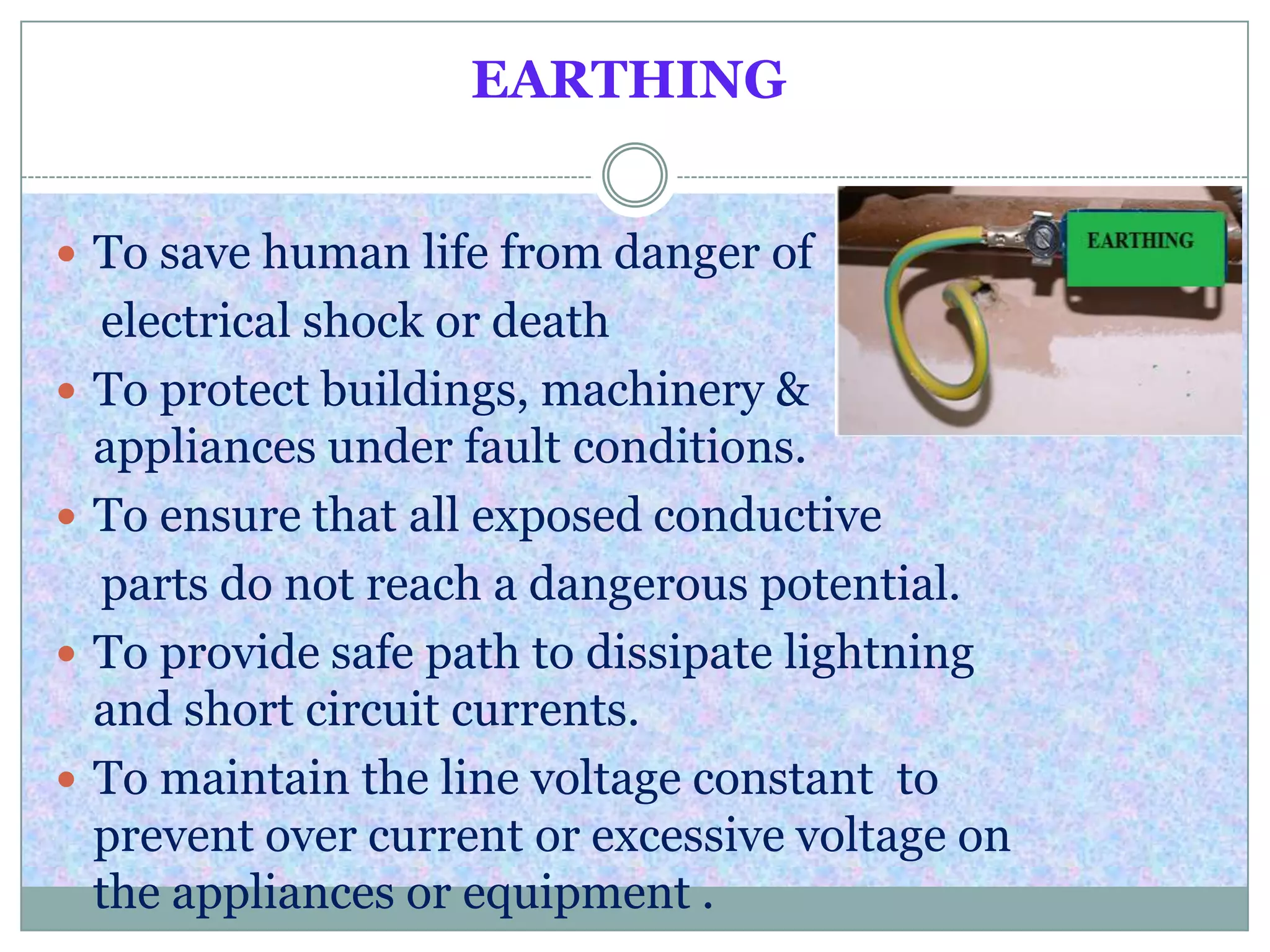

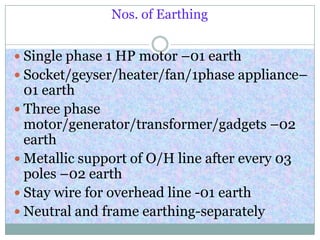

This document provides information about earthing systems including their purposes, specifications, types, and maintenance. The key points are:

1) Earthing systems are used to protect lives and equipment from electrical shock by providing a safe path for currents to travel and ensuring conductive parts do not reach dangerous potentials.

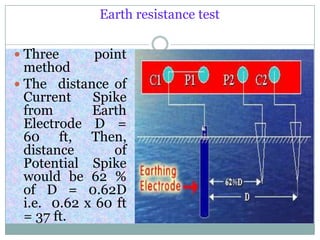

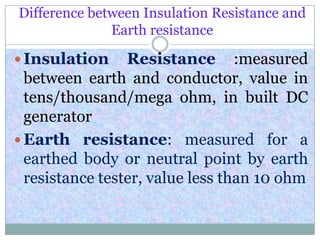

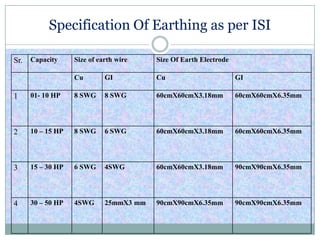

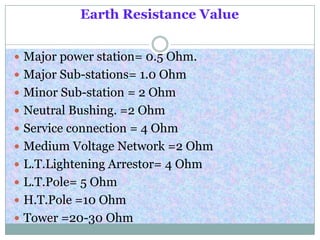

2) Recommended earth resistance values vary based on the equipment, with substations requiring lower values like 0.5-2 ohms and individual devices like poles needing 5-10 ohms.

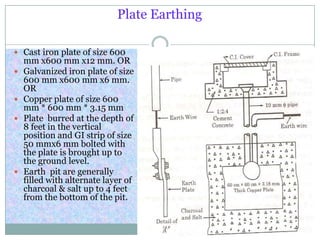

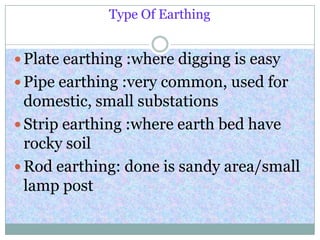

3) Common earthing types include pipe, plate, strip, and rod systems, with factors like soil conditions determining which type is best. Pipe earthing using galvanized iron pipes 10 feet long is very

![Pipe Earthing

GI pipe [C-class] of

75 mm diameter

10 feet long welded

with welded flat

having 4 numbers of

holes for connections

Earth pits are

generally filled with

alternate layer of

charcoal & salt or

earth reactivation

compound.](https://image.slidesharecdn.com/earthinginelectricalnetwork-130426195622-phpapp02/85/Earthing-in-electrical-network-7-320.jpg)