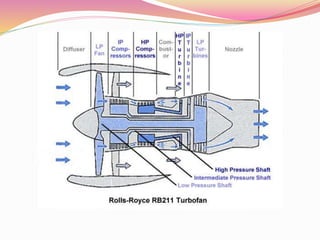

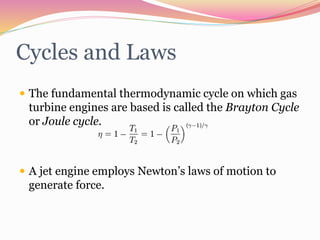

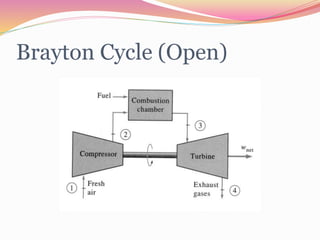

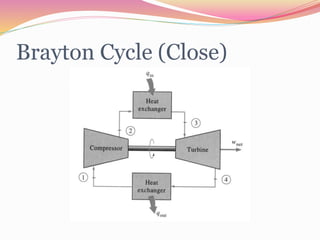

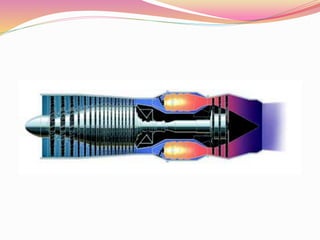

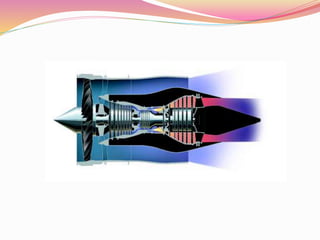

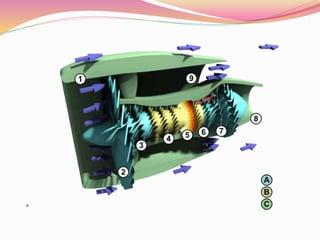

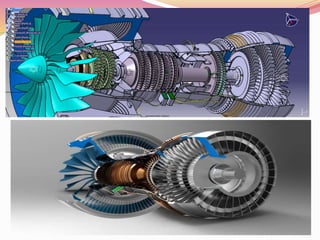

This document provides an overview of jet engine basics. It discusses the main types of jet engines including turbojet, turbofan, turboprop, and turboshaft. The turbofan engine is described as employing a bypass design that provides around 80% of total thrust from bypass airflows. The core components of a jet engine are also summarized, including the compressor, combustor, turbine, and their basic functions in the Brayton cycle that powers gas turbine engines.