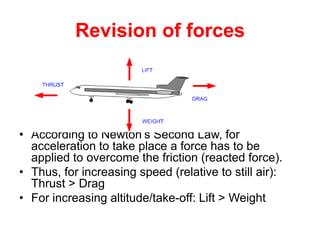

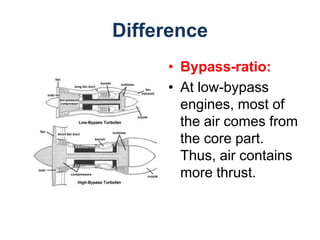

A jet engine works by compressing air from its intake with a fan, mixing this compressed air with fuel, combusting the air-fuel mixture, and expelling the hot combustion gases through a nozzle to generate thrust. The main stages of operation are intake, compression, combustion, and exhaust. Different types of jet engines include turbofans, turbojets, ramjets, and pulsejets. Jet engines make use of the compressibility of air to generate thrust by accelerating air and expelling it at high speeds from the rear of the engine.