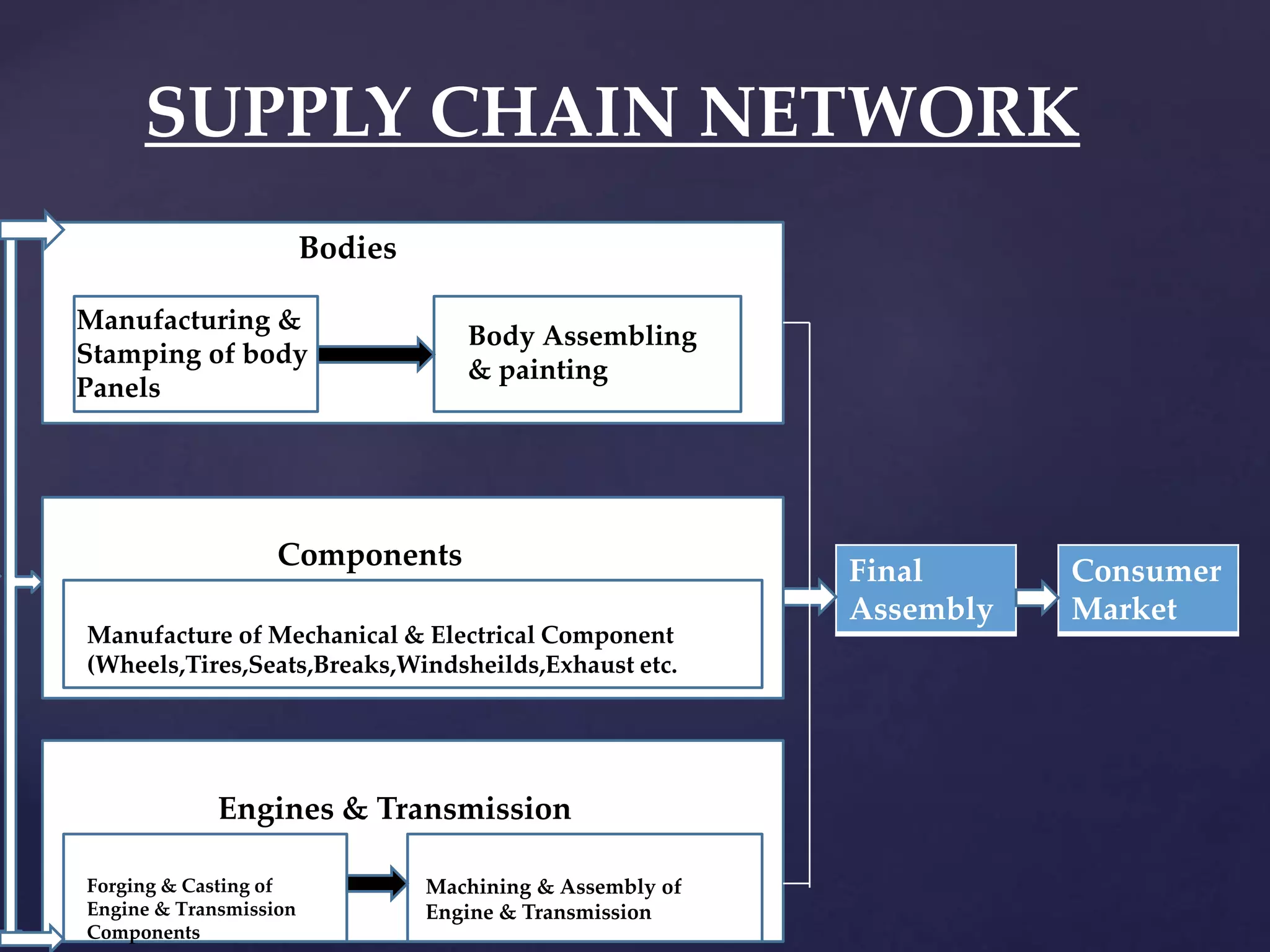

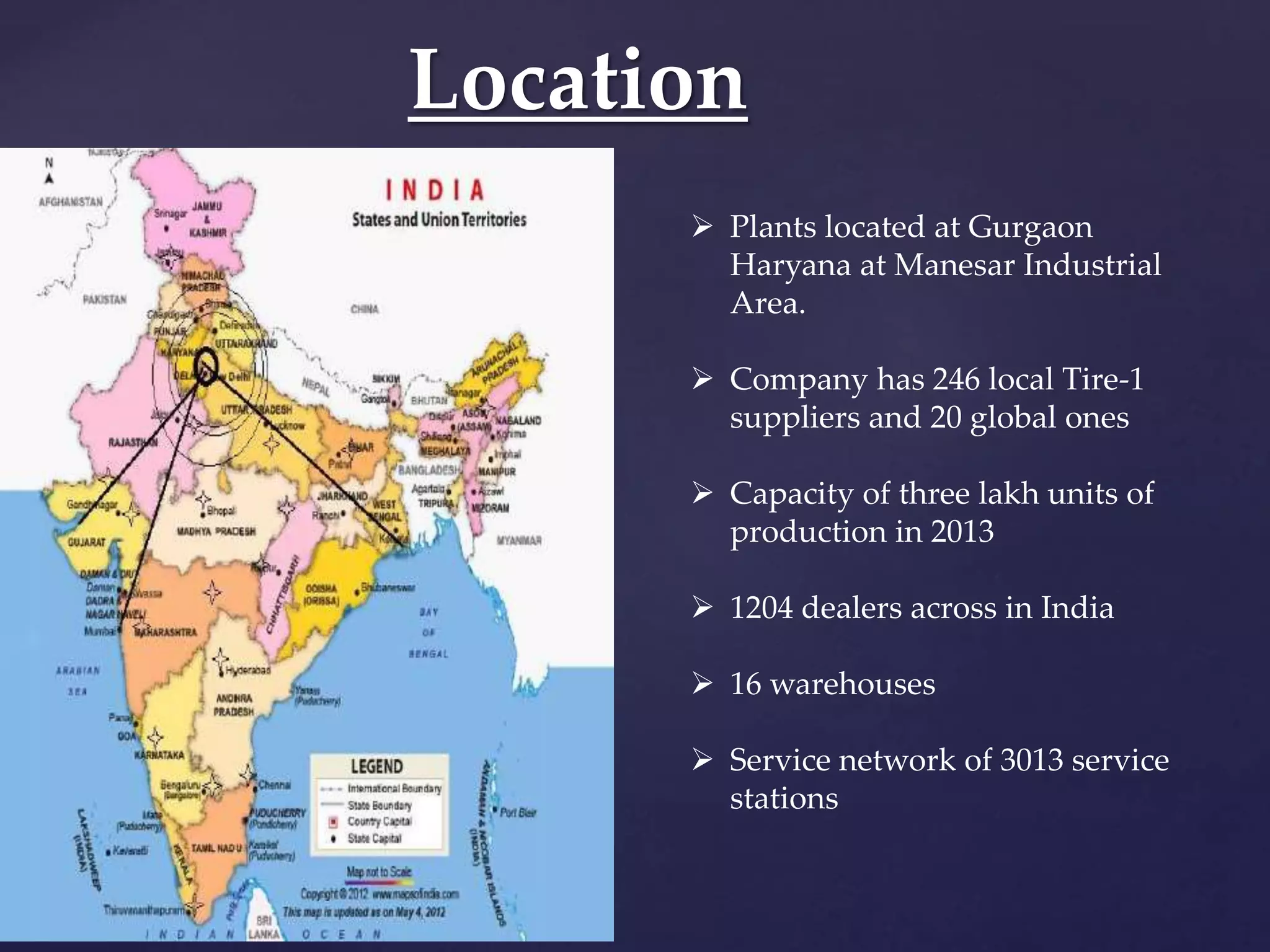

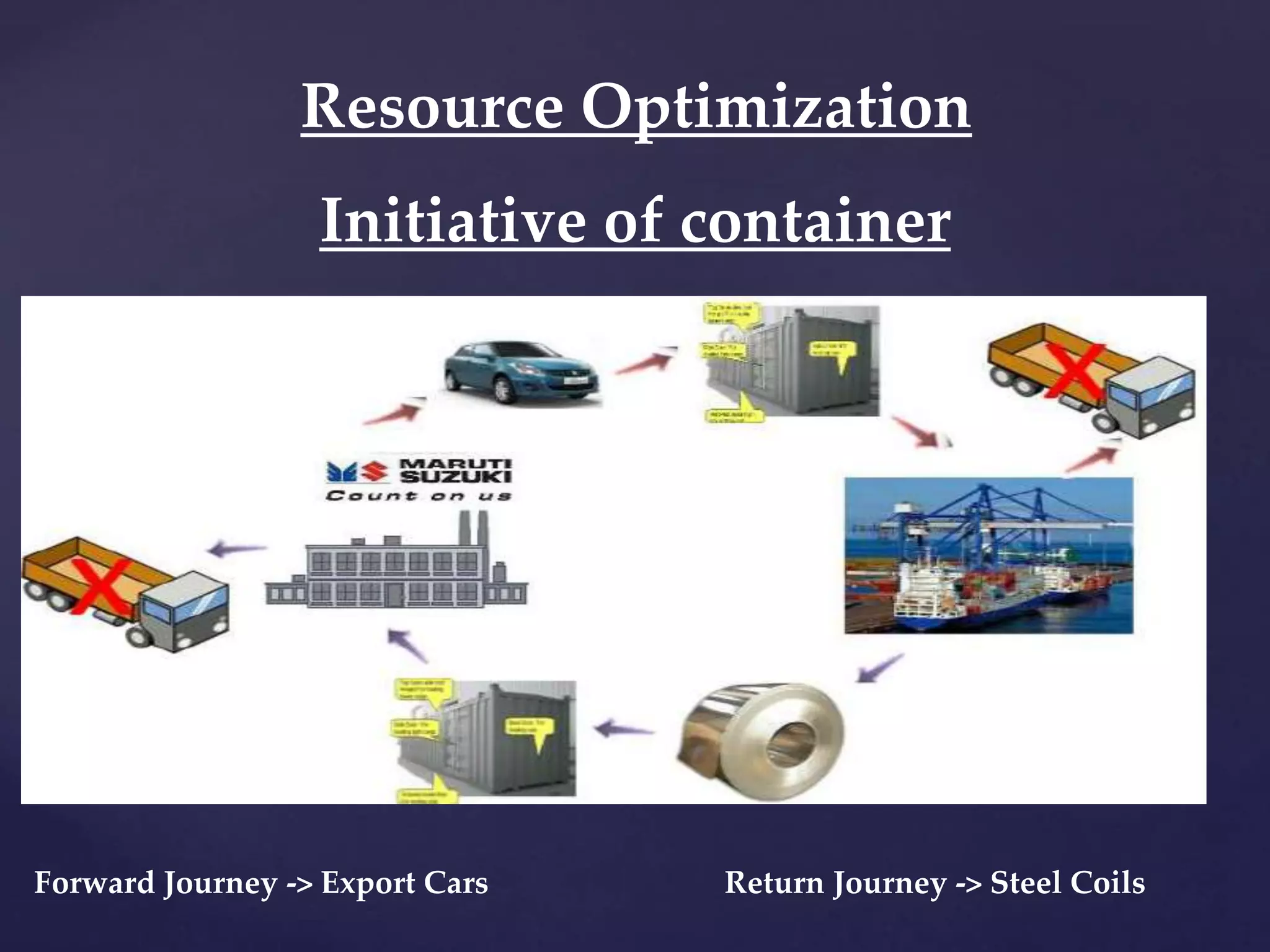

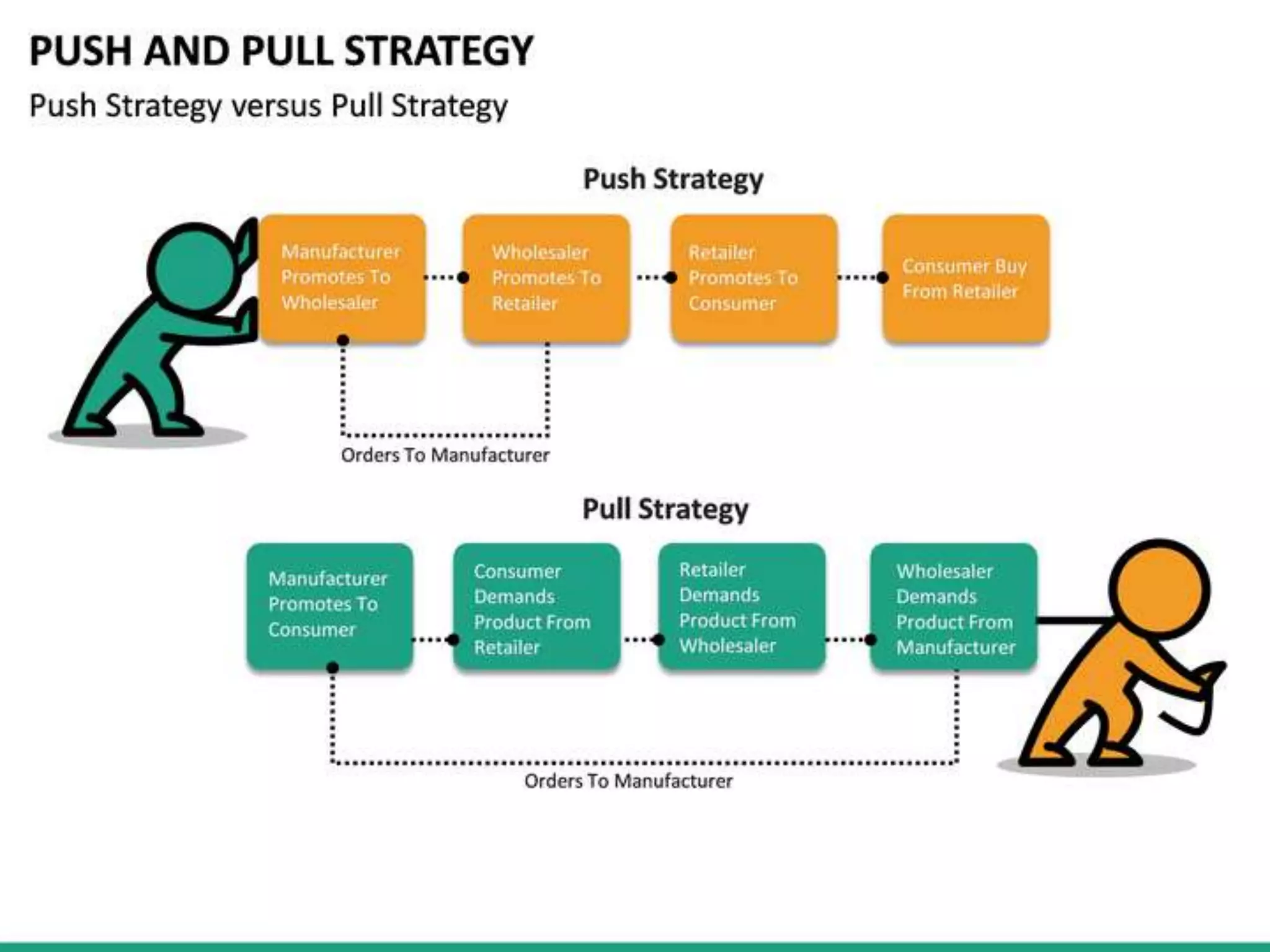

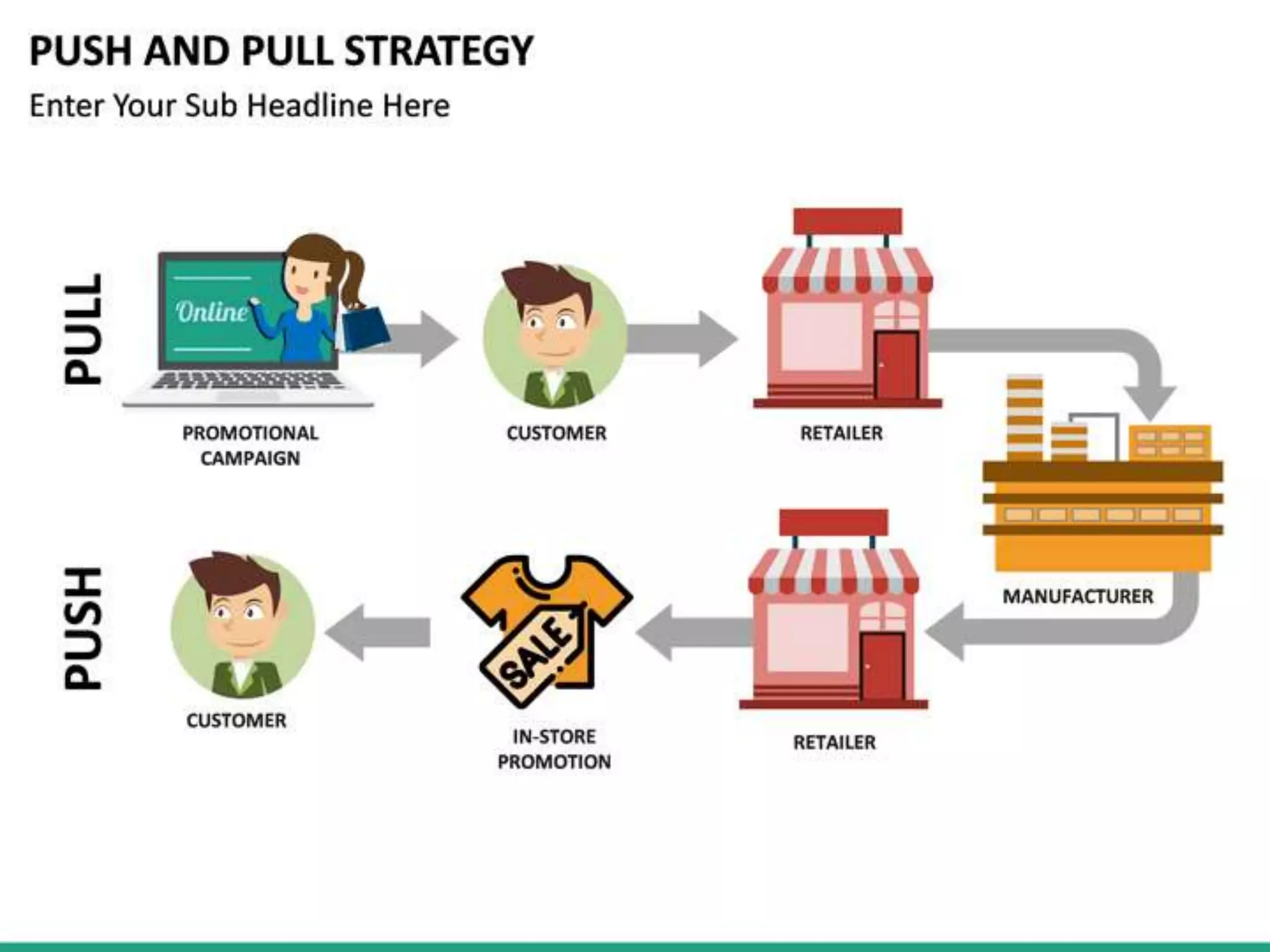

Maruti Suzuki has a strong supply chain capability due to its strategically aligned and collaborative supply chain ecosystem. It sources 70-80% of components locally and uses a "milk run" system and container optimization to reduce logistics costs. Maruti Suzuki's supply chain outcomes include low costs, reduced time, and reduced risk due to its modern manufacturing facilities and pull-based production system.