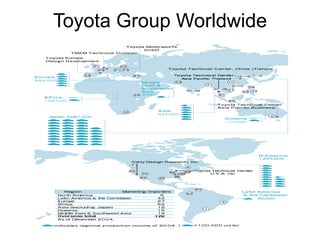

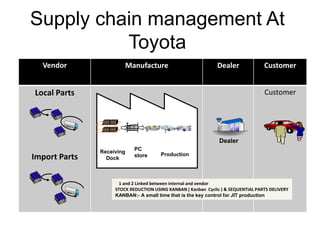

Toyota is a leading Japanese automotive manufacturer established in 1937, known for its production efficiency and innovation in lean manufacturing. The company operates under five brands and has a strong presence in global markets, targeting various customer segments and focusing on quality and dependability. Despite facing challenges like large-scale recalls, Toyota continues to expand its sales and operations in emerging markets with a reputation for environmentally friendly vehicles.