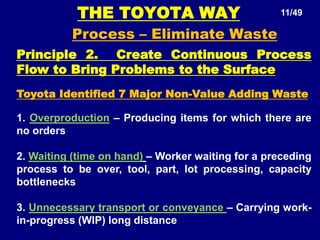

The document outlines 14 management principles from Toyota's production system (TPS), also called the Toyota Way. The principles are organized under four categories: philosophy, process, people/partners, and problem solving. The philosophy principle emphasizes long-term decision making. The process principles focus on eliminating waste through continuous flow, pull systems, leveling workload, and stopping production to fix quality problems. The people/partners principles involve respecting, challenging, and growing employees and suppliers. The problem solving principles prioritize continual learning and improvement. Overall, the Toyota Way principles aim to provide high quality products through efficiency and respect for people.