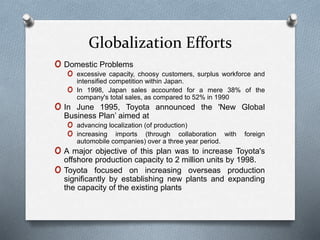

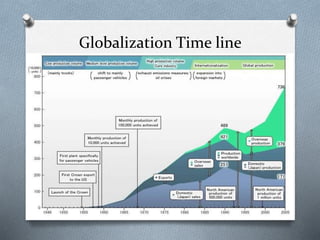

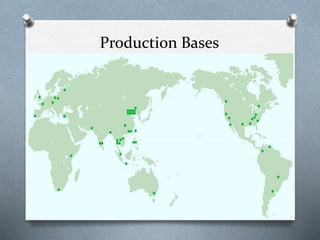

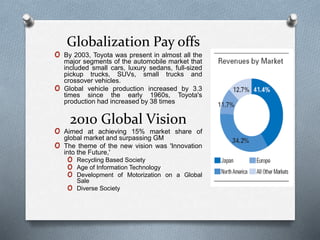

Toyota faced domestic problems in Japan in the late 1990s which led it to announce a globalization plan in 1995. The plan aimed to increase offshore production capacity and global vehicle sales. Toyota expanded globally by establishing local sales networks, auto parts bases, and joint ventures to build vehicles locally. It opened production bases around the world and established global production centers to ensure consistent quality, training, and development across locations. By localizing manufacturing, Toyota was able to achieve a presence in almost all major global vehicle segments and markets by 2010.