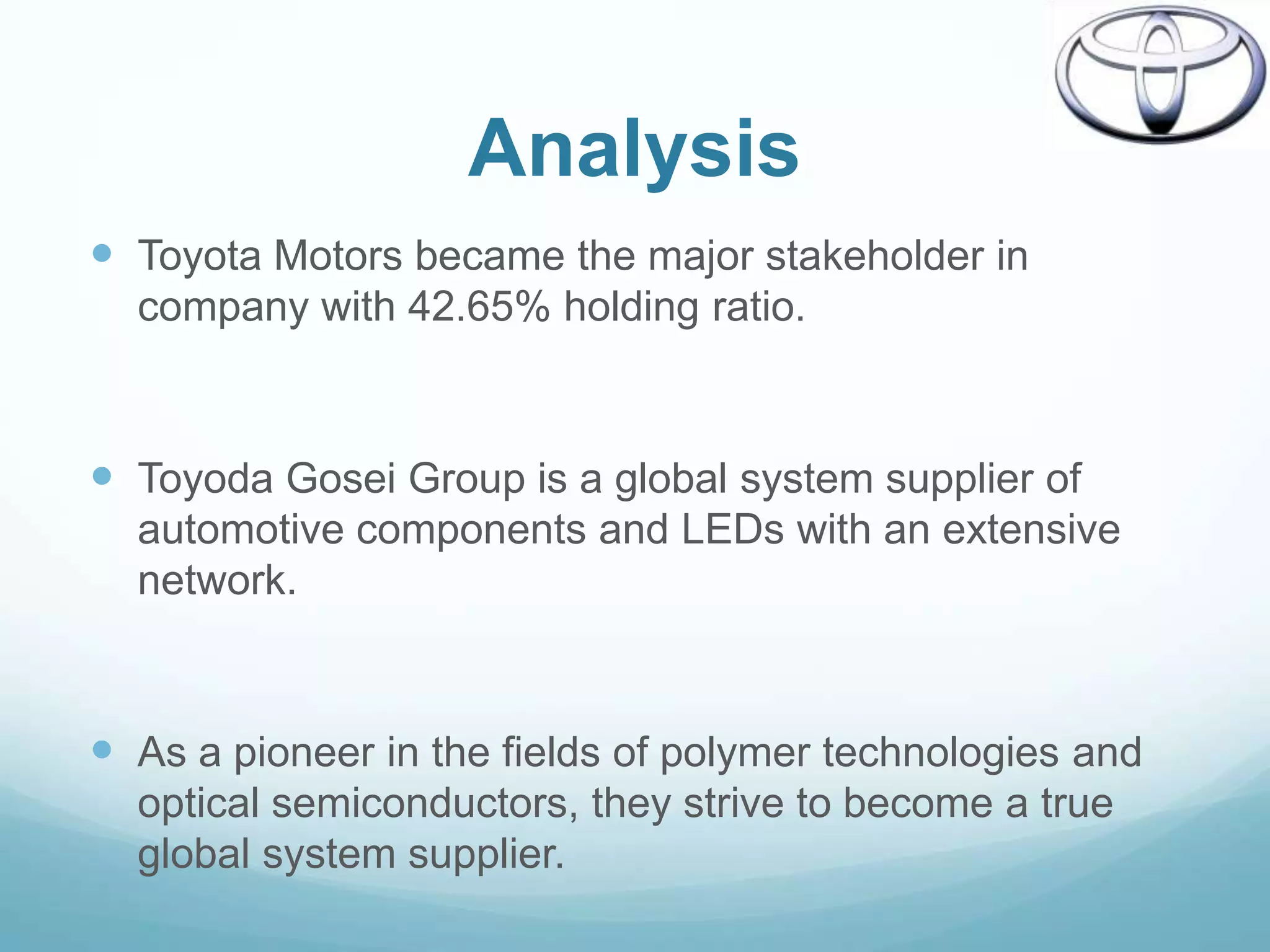

The Toyota Group is a conglomerate, primarily known for Toyota Motor Corporation, the largest carmaker globally. It aims to innovate in mobility and sustainability, emphasizing environmental action and quality in its operations. Its corporate strategy includes diversification, integration, joint ventures, and thorough market analysis to maintain its leading position in the automotive industry.

![Their Very First Prototype

[Model A1 1934]](https://image.slidesharecdn.com/toyotafinal-130327130344-phpapp01/75/Toyota-Analysis-of-Vision-Statement-Corporate-Level-Strategies-SWOT-21-2048.jpg)

![Model G1 [1935]

Model AA, AB, AC [1935,1936]](https://image.slidesharecdn.com/toyotafinal-130327130344-phpapp01/75/Toyota-Analysis-of-Vision-Statement-Corporate-Level-Strategies-SWOT-22-2048.jpg)

![Segmental Sales of Toyota

[2011-12]

Source: Toyota Global](https://image.slidesharecdn.com/toyotafinal-130327130344-phpapp01/75/Toyota-Analysis-of-Vision-Statement-Corporate-Level-Strategies-SWOT-27-2048.jpg)

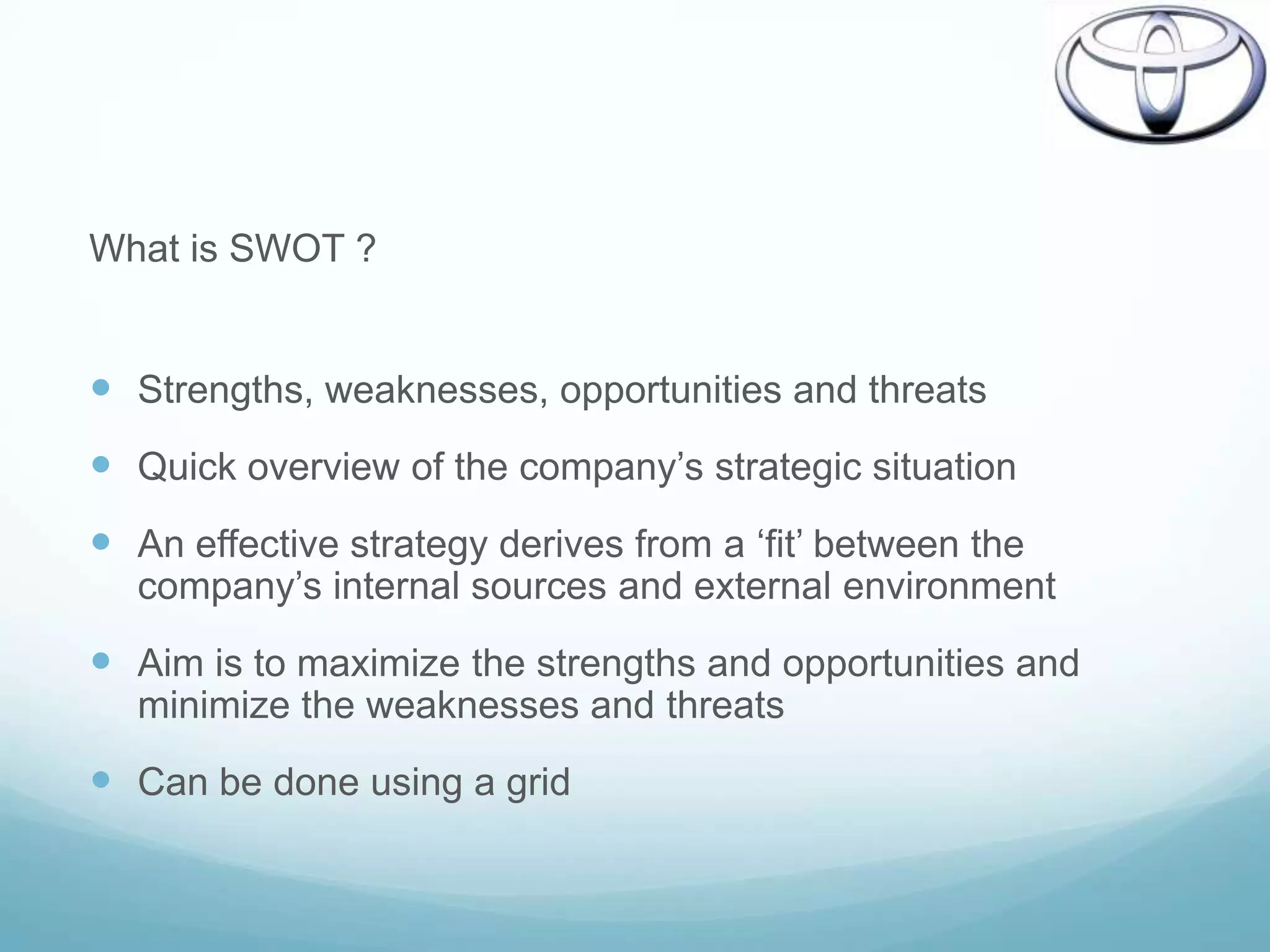

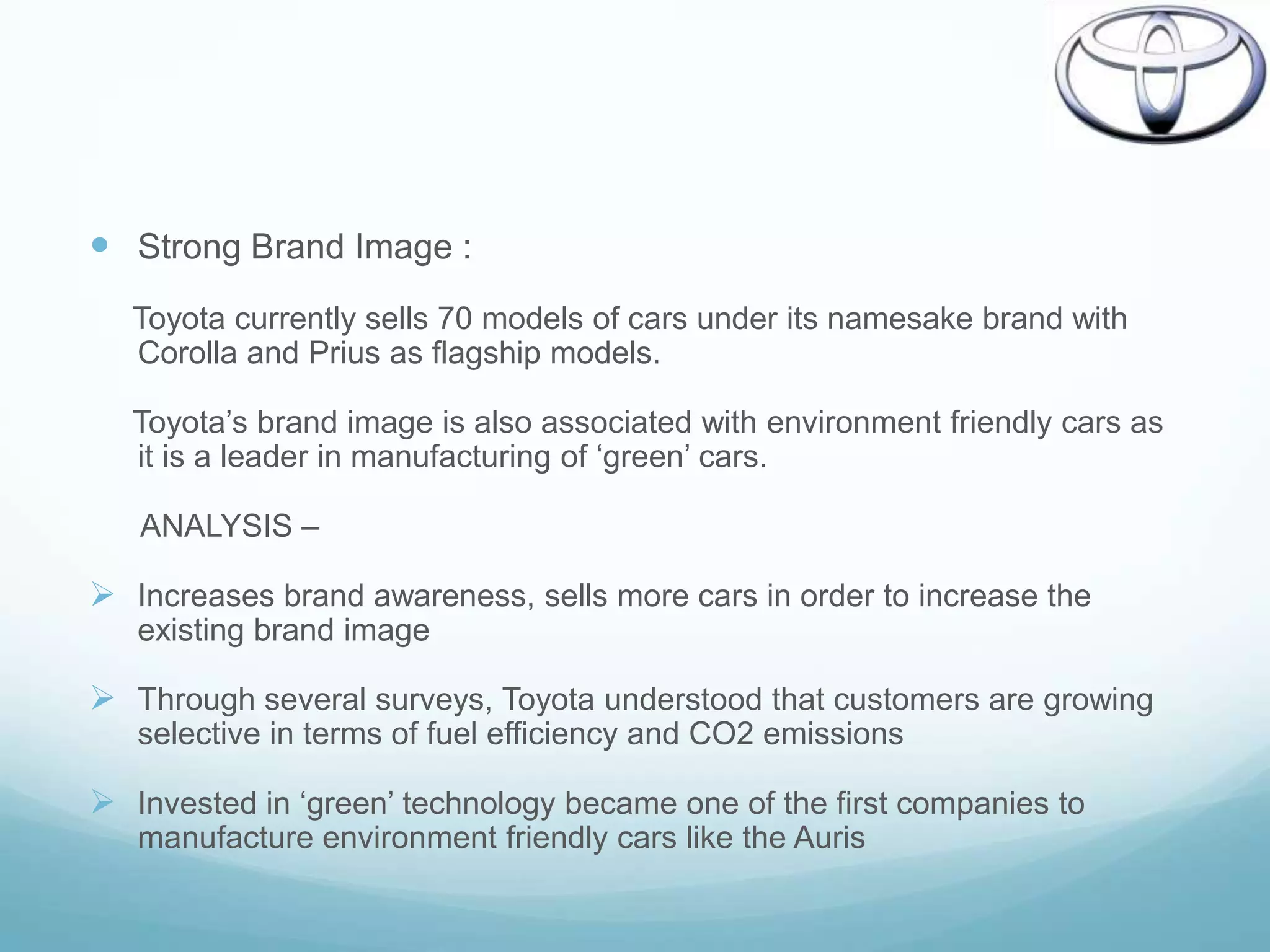

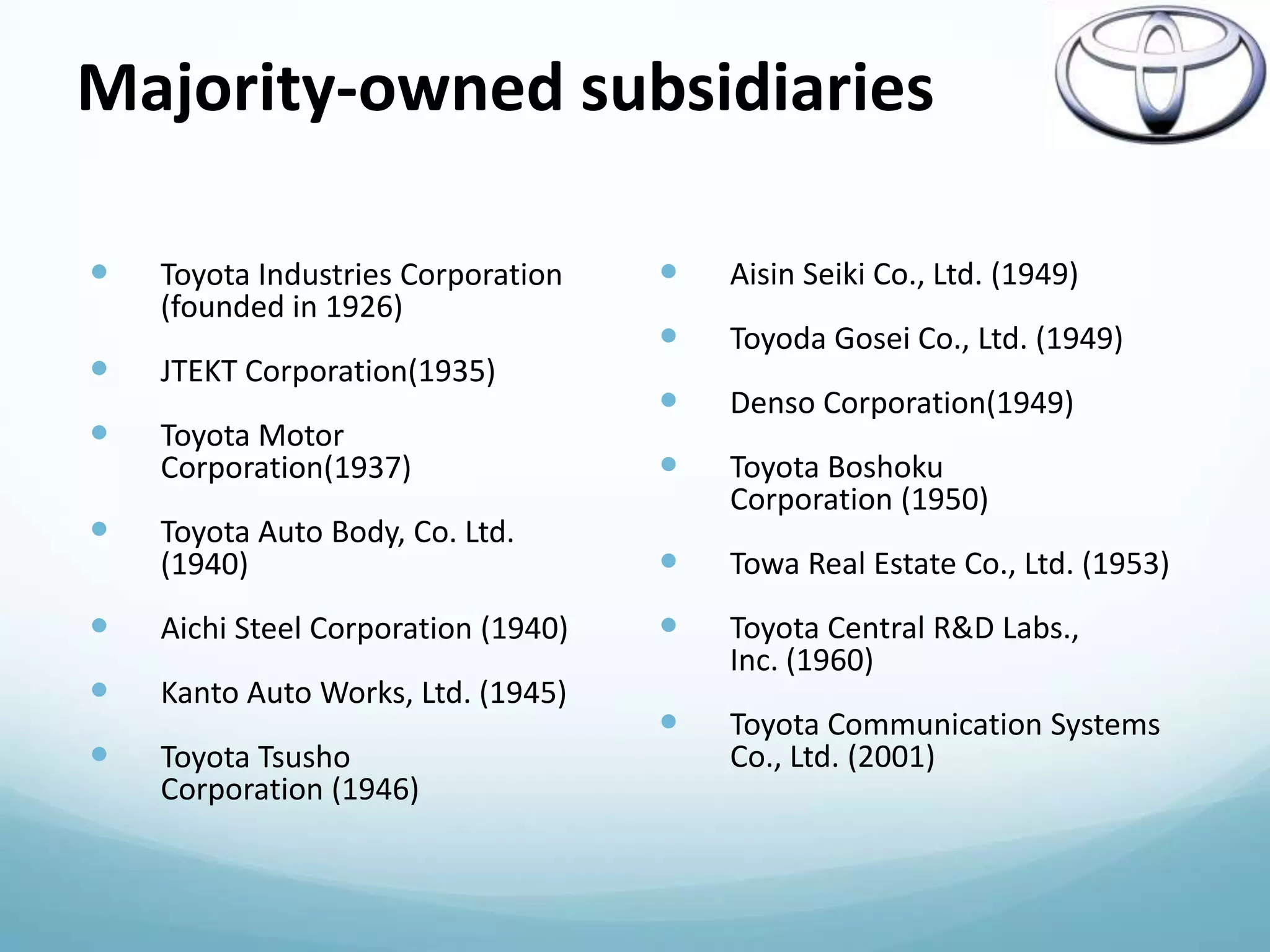

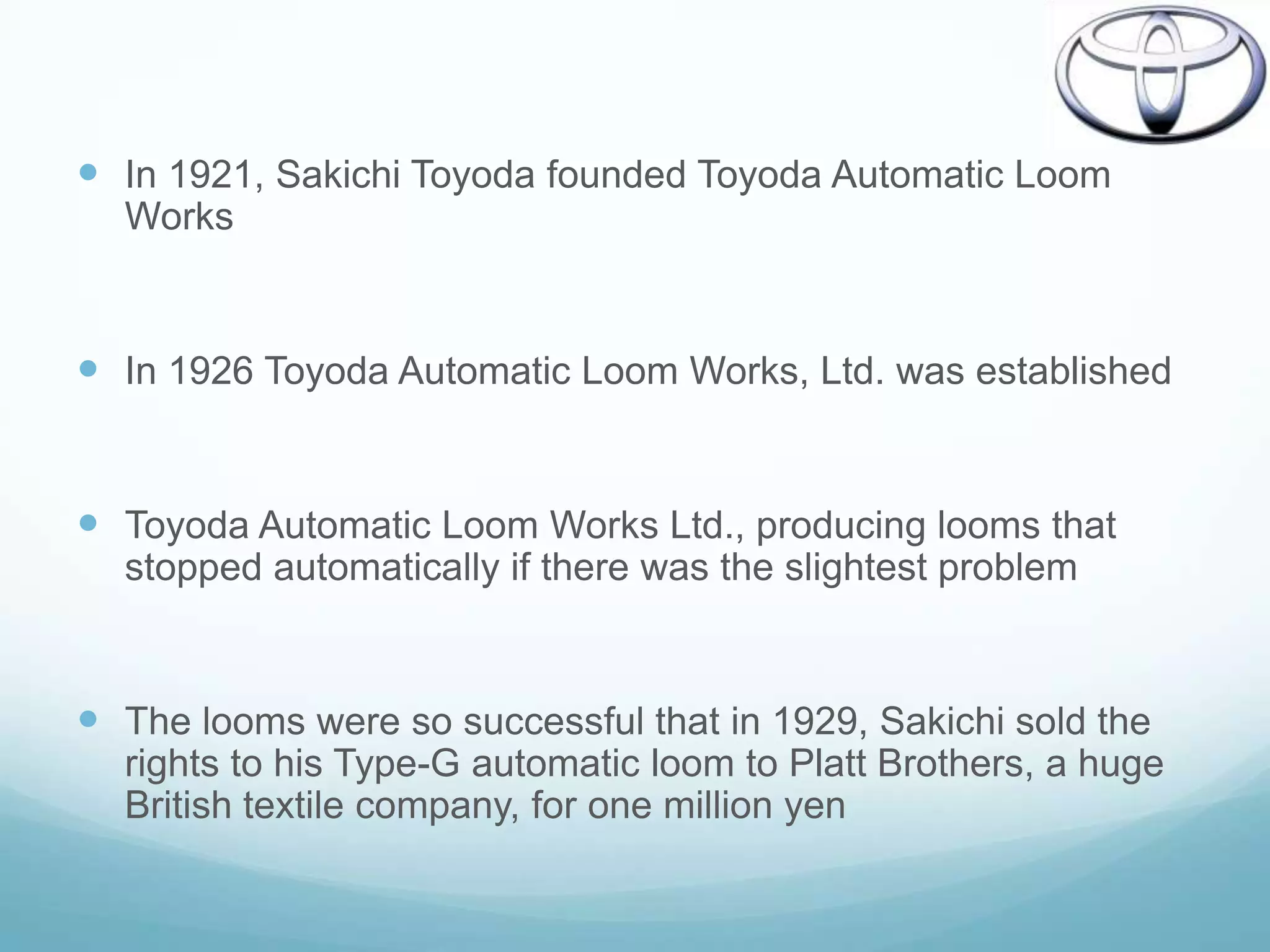

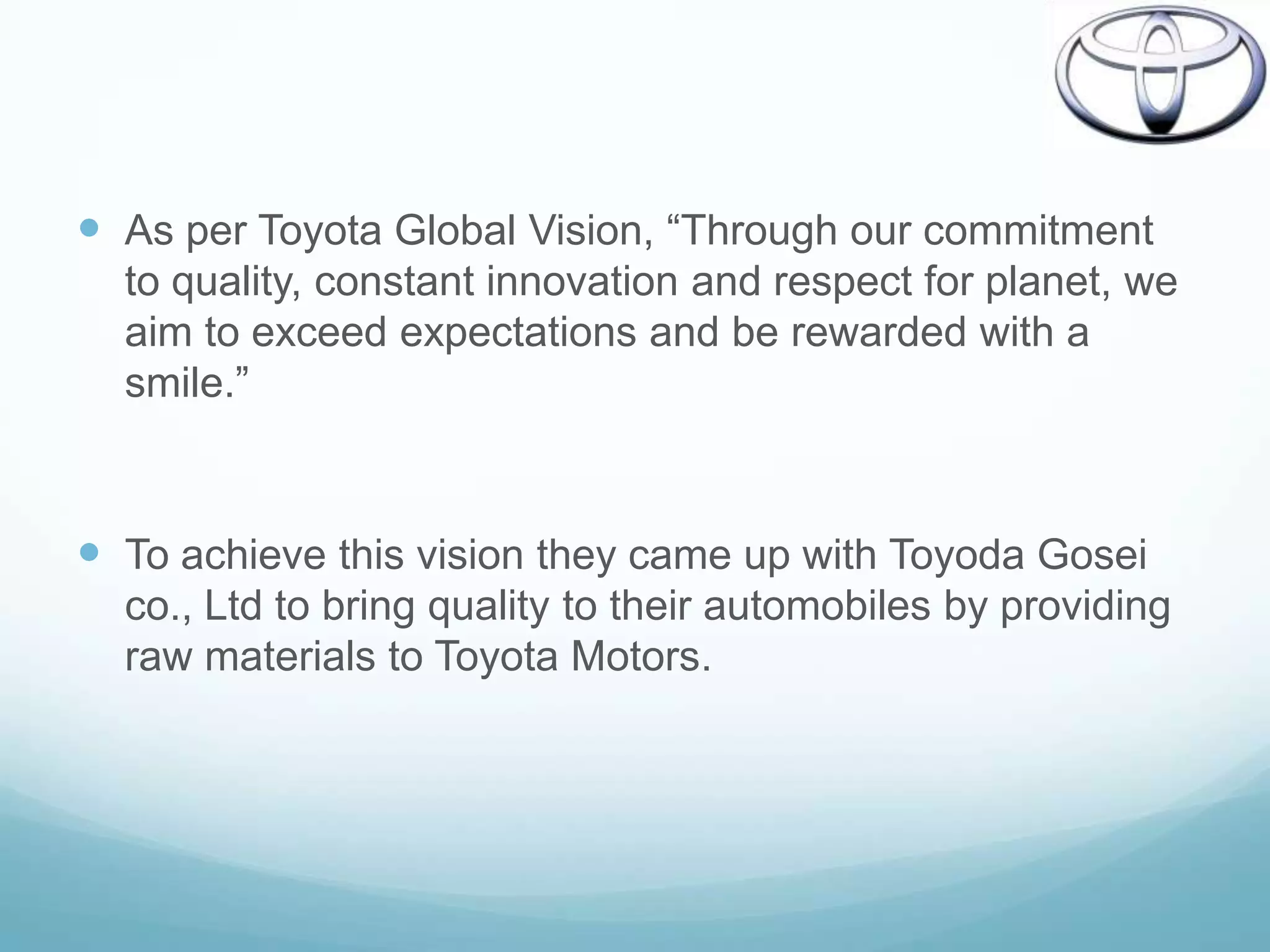

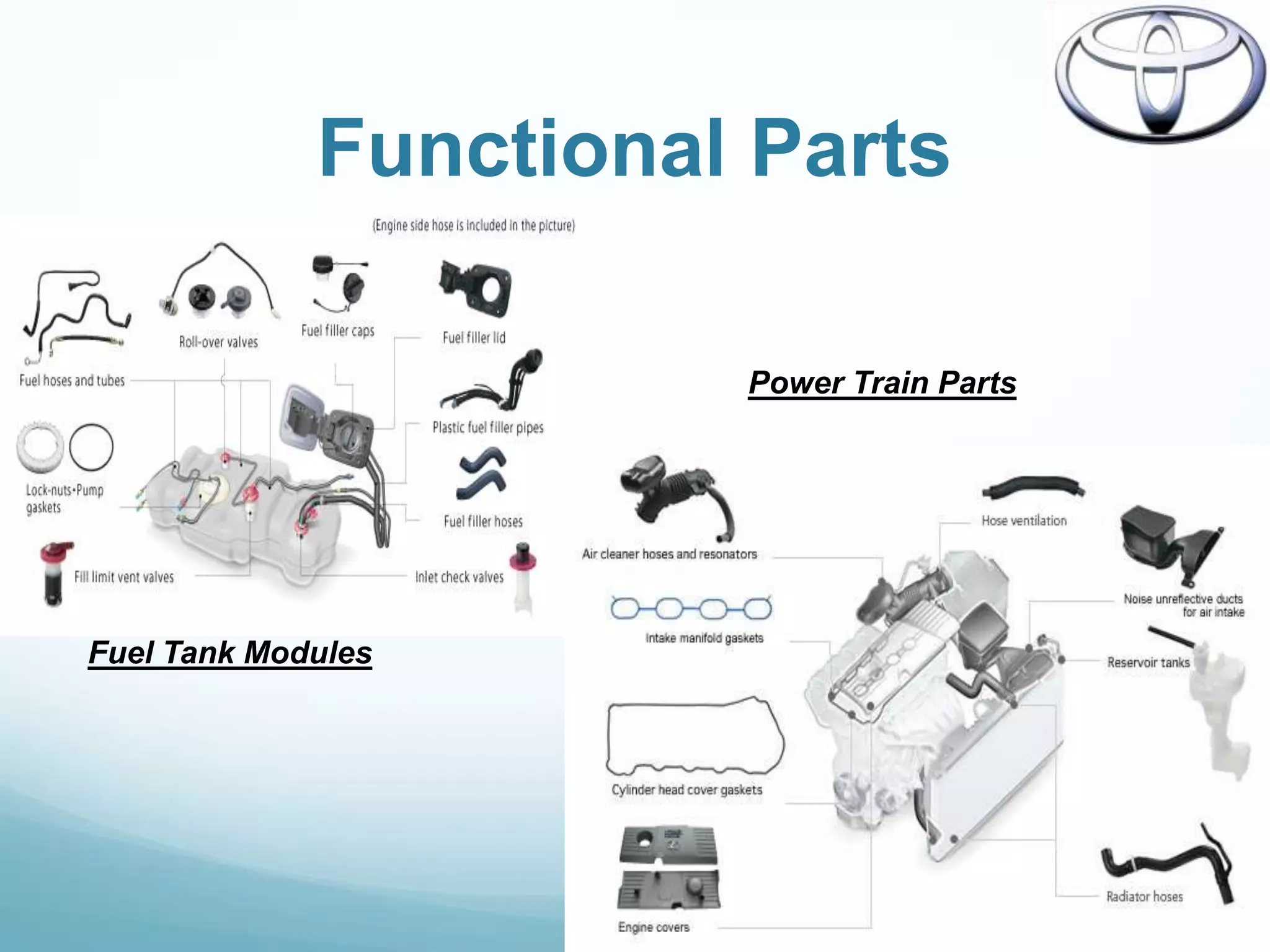

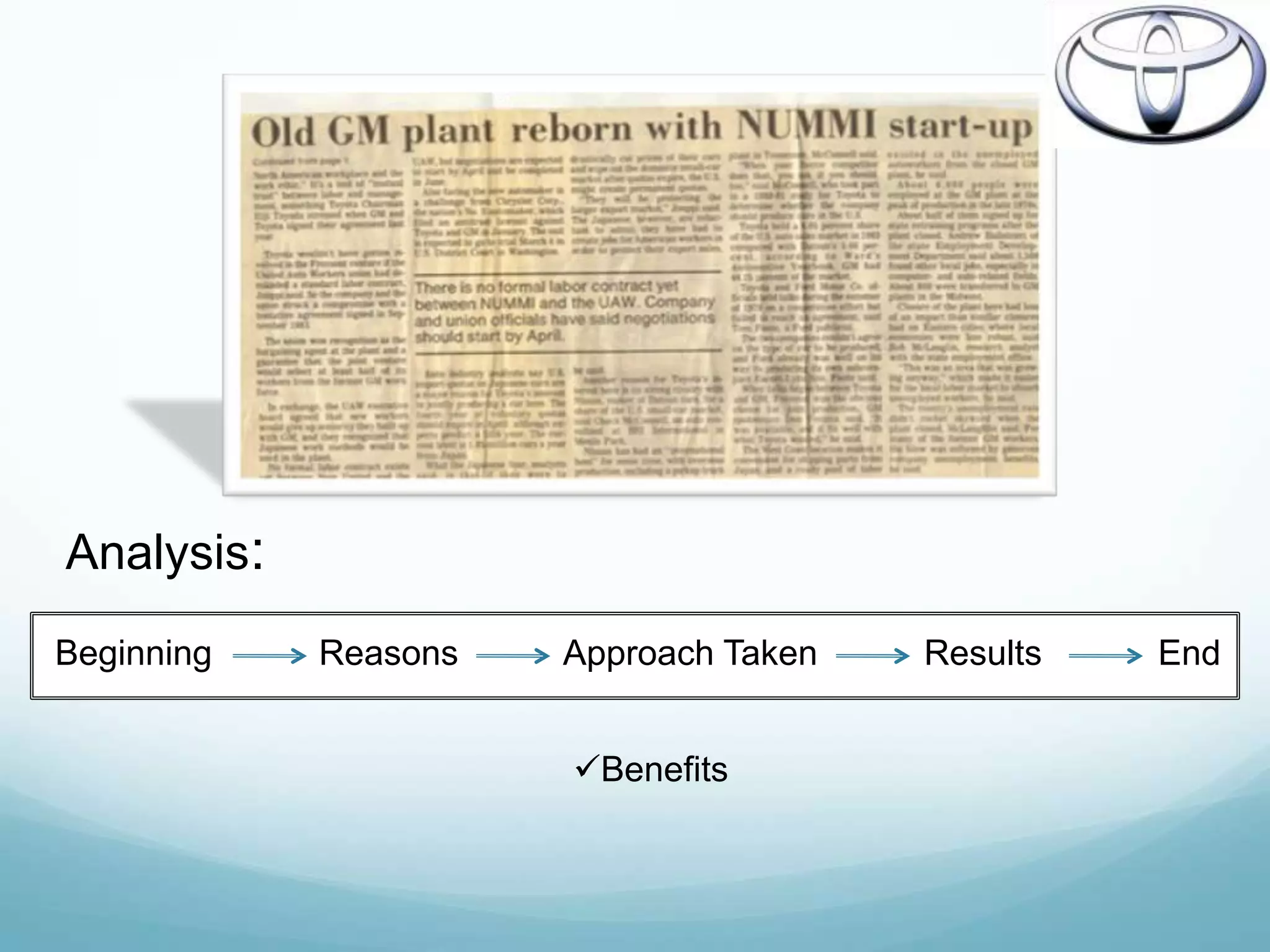

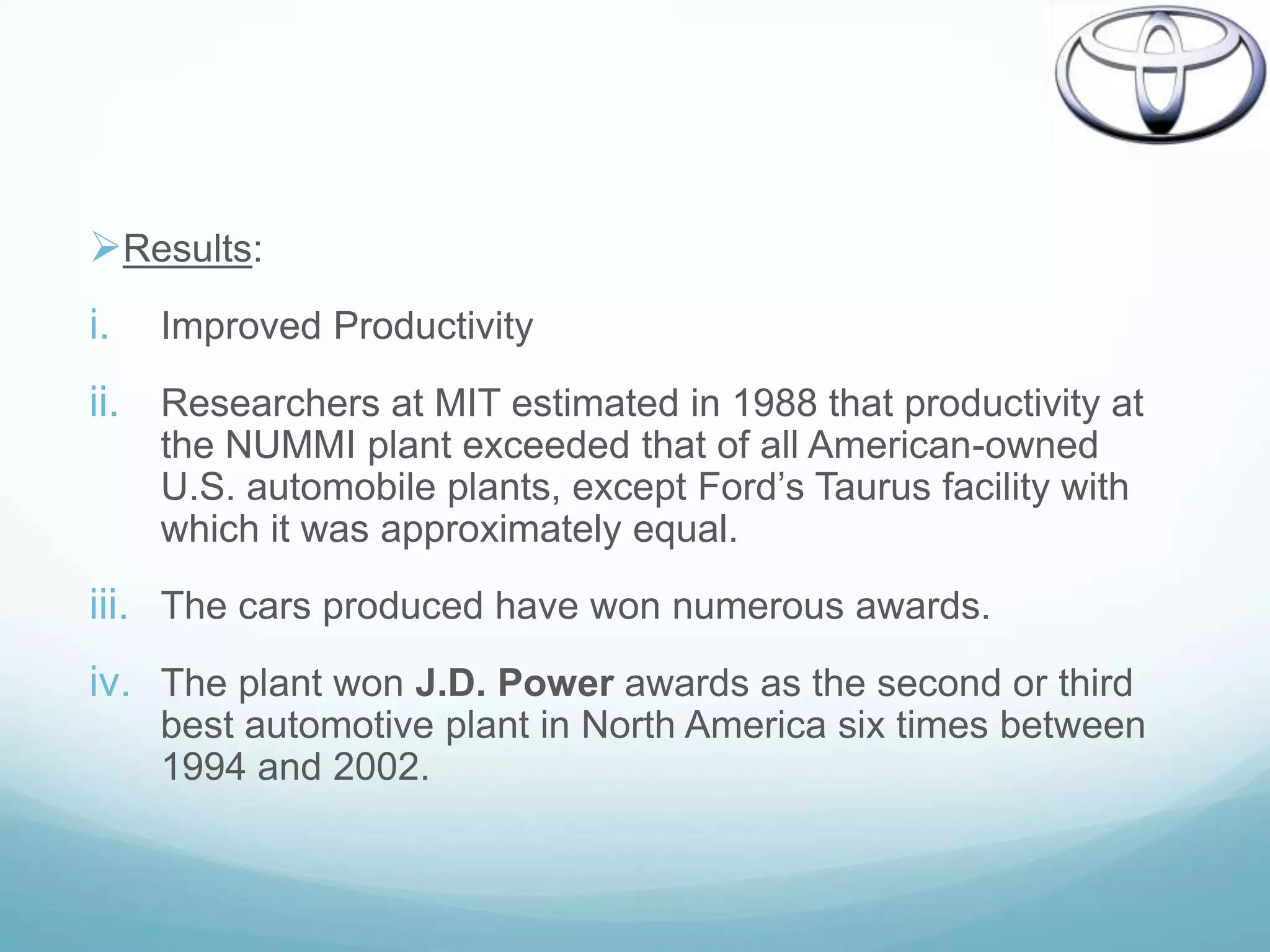

![V. End of Joint Venture

(Divestment)

Calendar U.S. sales

June 29,2009 - General Motors bails out. Chg/yr.

Year (vehicles)

2004 4,707,416

Attempts to sustain the venture fail. 2005 4,517,730 4.0%

2006 4,124,645 8.7%

July 10, 2009 - GM Files for bankruptcy.

2007 3,866,620 6.3%

August 27, 2009 - Toyota makes a decision. 2008] 2,980,688 22.9%

2009 2,084,492 30.1%

April 1, 2010 - NUMMI Plant ceases operations.

General Motors

Region 2006 2007 2008 2009

N.America 2,738.3 2,822.2 2,441.8 1,975.4

Europe 1,124.1 1,238.6 1,119.5 886.0

Asia 1,106.7 1,329.6 1,438.6 1,533.9

Worldwide 7,921.6 8,429.3 7,996.1 6,979.6

Toyota Sales by region](https://image.slidesharecdn.com/toyotafinal-130327130344-phpapp01/75/Toyota-Analysis-of-Vision-Statement-Corporate-Level-Strategies-SWOT-59-2048.jpg)