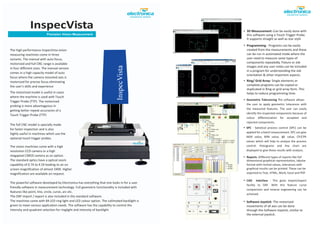

The document outlines the features and specifications of InspecVista vision measuring machines, which support 3D measurements using various camera and software capabilities. It highlights the machines' precision, programmable lighting control, and options for motorized operations and automated measurement programs. Additionally, the document details the accessories available, such as touch trigger probes and various lens options for enhanced measurement accuracy and versatility.