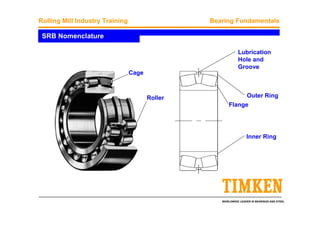

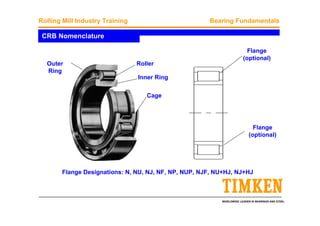

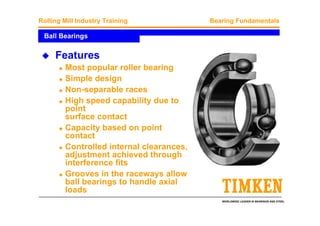

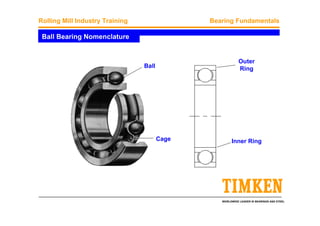

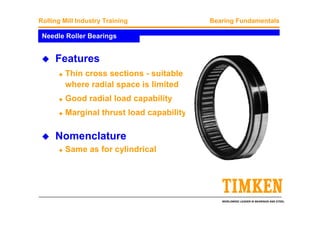

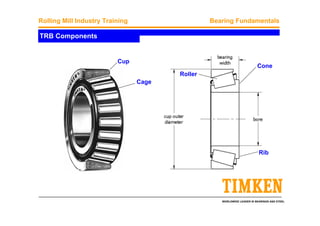

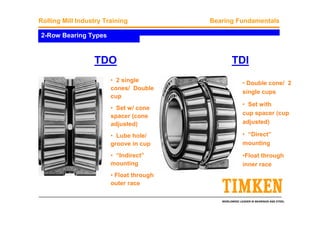

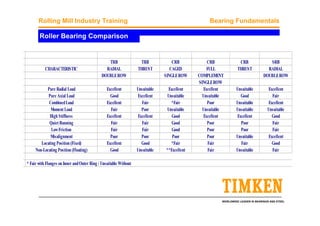

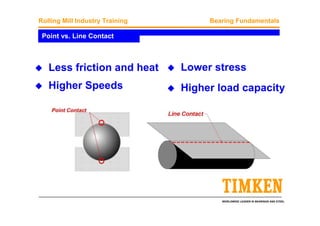

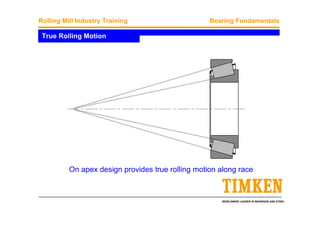

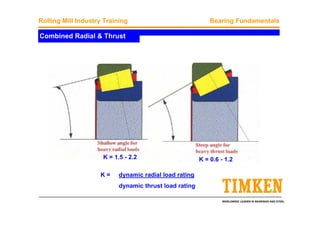

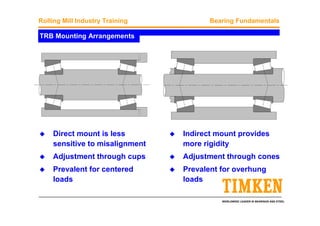

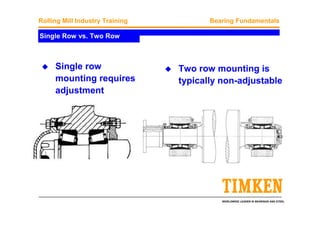

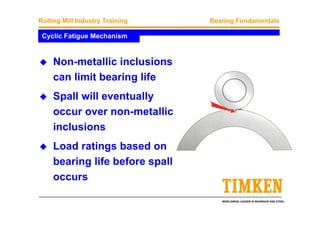

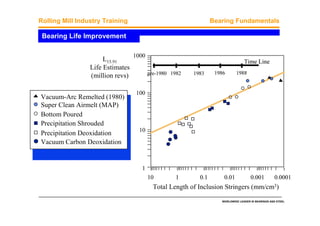

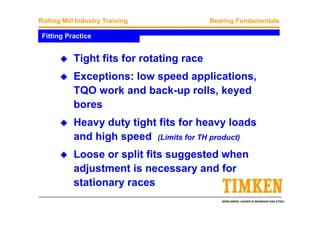

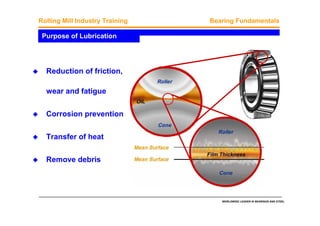

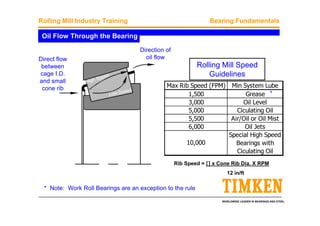

The document provides an overview of bearing fundamentals training for the rolling mill industry. It discusses different bearing types including tapered roller bearings, their components and features. It also covers topics like bearing metallurgy and fatigue, lubrication, fitting practices, and a comparison of bearing types for different load capabilities.