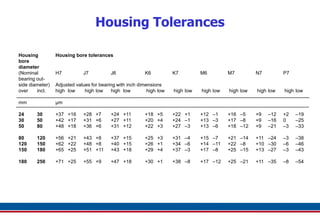

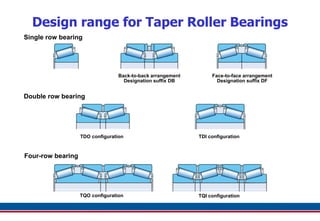

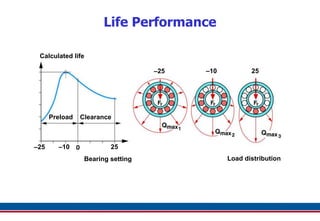

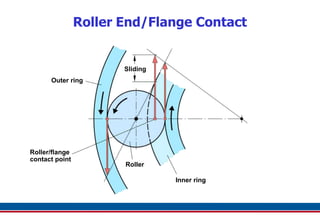

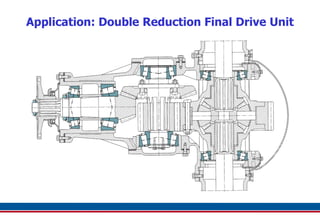

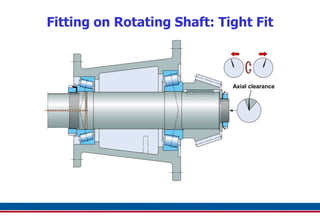

Taper roller bearings are used in a variety of industrial applications. They consist of an inner ring, outer ring, and tapered rollers. Proper installation is important for long life and performance. Bearings must be carefully fitted and mounted, ensuring correct tolerances, preload, and lubrication to transfer loads efficiently.