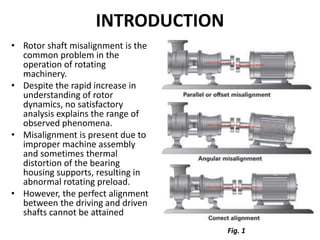

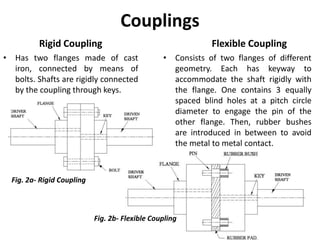

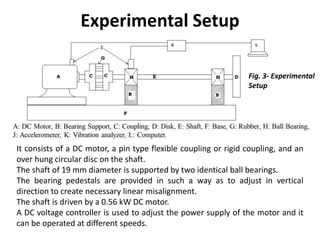

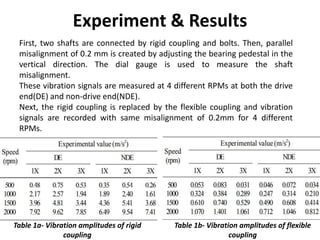

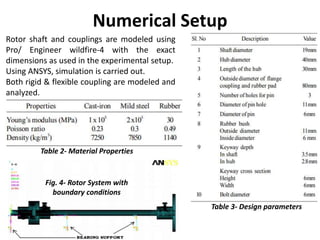

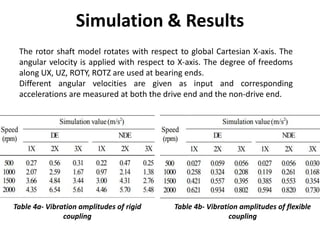

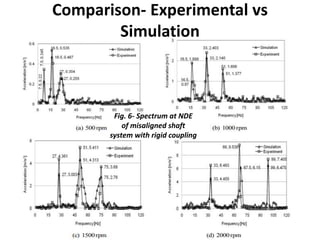

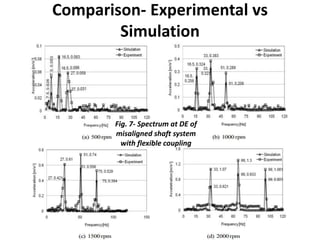

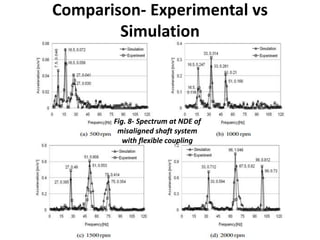

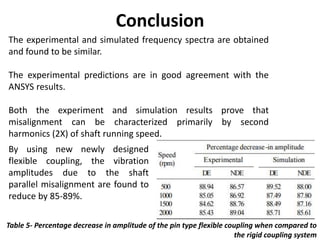

This document presents a study on vibration analysis of parallel misaligned shafts using both rigid and flexible couplings, focusing on the impact of misalignment on rotor dynamics characteristics. Experimental and simulation results demonstrate that misalignment can be primarily characterized by second harmonics of the shaft running speed, with a significant reduction in vibration amplitudes (85-89%) when using a flexible coupling. The findings suggest that both experimental and simulation results align closely, offering valuable insights into rotor shaft misalignment issues.

![Reference

[1] Vaggeeram Hariharan1 and PSS.Srinivasan, “Vibration analysis of

parallel misaligned shaft with ball bearing system”, Songklanakarin J. Sci.

Technol. 33 (1), 61-68, Jan. - Feb. 2011

[2] http://www.vibelube.com/1110alignments/](https://image.slidesharecdn.com/vibration-190413180658/85/Vibration-analysis-due-to-shaft-misalignment-14-320.jpg)