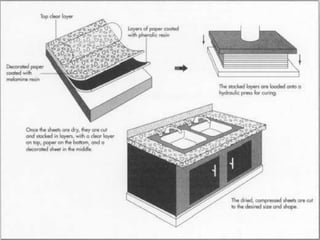

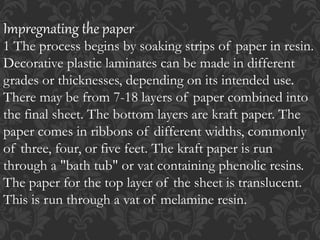

Lamination is a process that bonds multiple layers of materials together to improve the strength and properties of the composite material. There are various lamination processes that are used depending on the materials. Decorative high-pressure laminates are commonly used for furniture and consist of layers of paper soaked in resins and bonded under heat and pressure to form a durable surface. Laminates undergo various quality tests and standards and are used in applications such as kitchen countertops, walls, and furniture.

![A common anti-fungi standard is the ASTM G21-09.

Not all manufacturers will take the initiatives for product

R&D for anti-Fungi attributes. Manufacturers like Maica

Laminates send their products for laboratory tests for

certification following the ASTM G21-09 standard,[6]

while Formica (South America) partners with Microban

Protection,which is a company manufacturing additives,

including the anti-bacterial additives.

ANTI FUNGI](https://image.slidesharecdn.com/presentation1-170222190123/85/laminates-BUILDING-MATERIAL-LAMINATE-15-320.jpg)