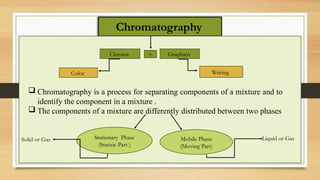

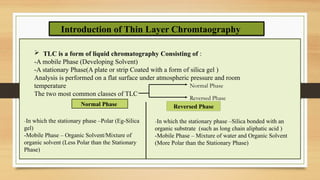

This presentation provides an in-depth overview of Thin Layer Chromatography (TLC), a widely used analytical technique in chemistry and pharmaceutical sciences for separating and identifying compounds. It explains the principle, procedure, and applications of TLC, along with its advantages and limitations.

Topics Included-

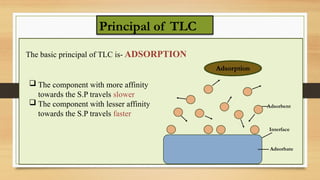

Principle and working mechanism of TLC

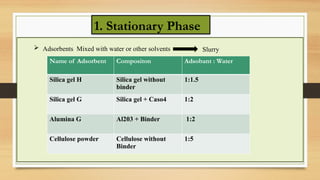

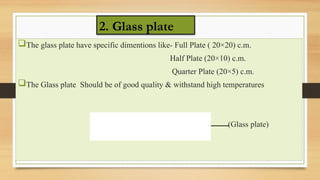

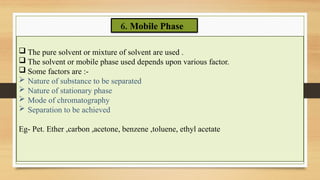

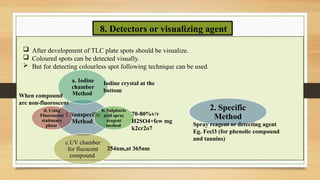

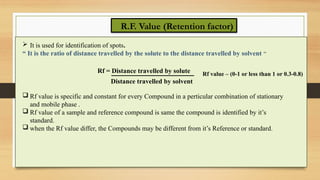

Components of TLC: stationary phase, mobile phase, and sample

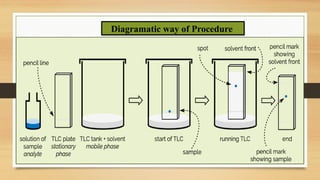

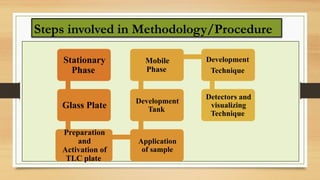

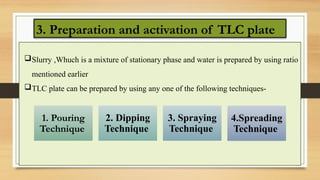

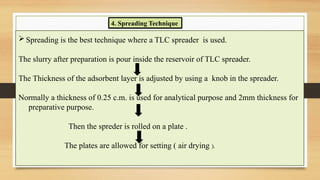

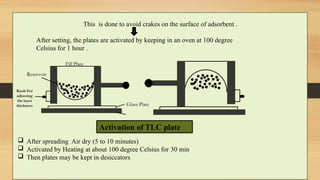

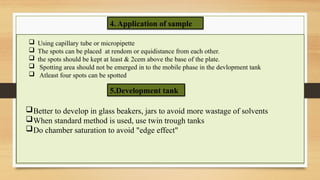

Step-by-step experimental procedure

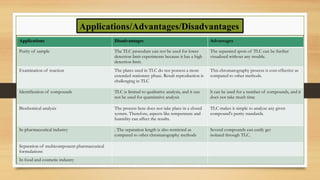

Applications in pharmaceutical analysis and quality control

Advantages, limitations, and comparison with other chromatographic techniques