This document provides an overview of steam power plants. It discusses:

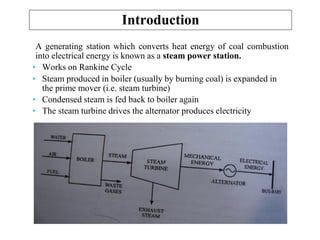

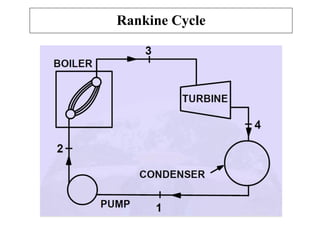

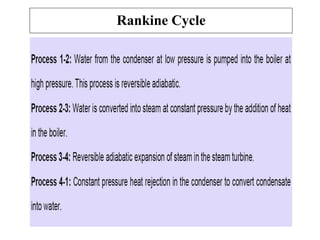

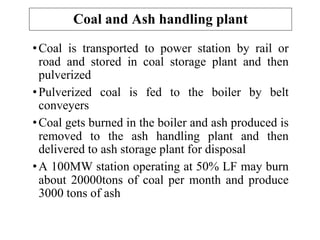

- How steam power plants work by converting heat from coal combustion into electrical energy using the Rankine cycle.

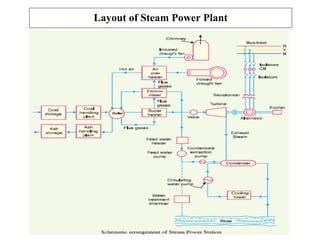

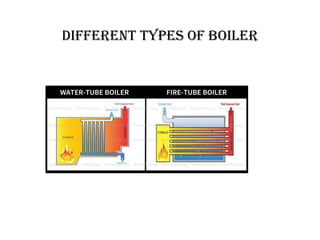

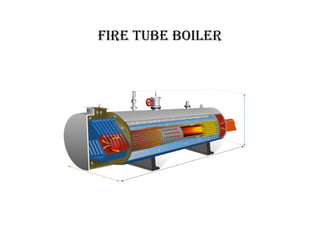

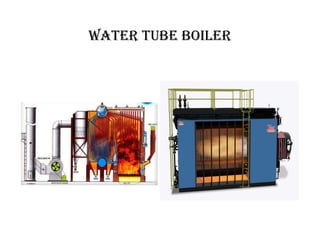

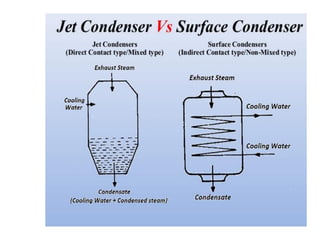

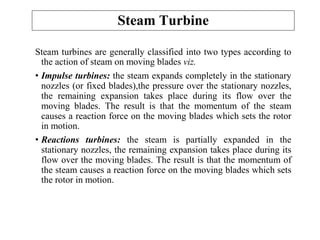

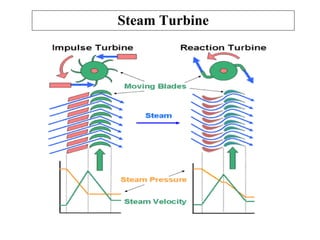

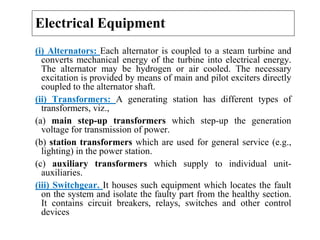

- The key components of steam power plants including boilers, turbines, generators, condensers and their functions.

- Factors considered in siting power plants such as fuel supply, water availability, and transportation.

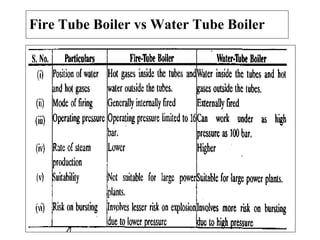

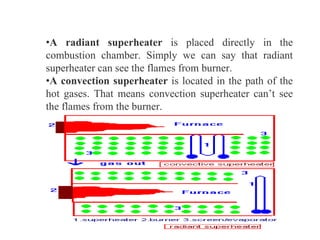

- Types of boilers, turbines, condensers and their advantages.

- Other equipment like water treatment plants, electrical components and their roles.

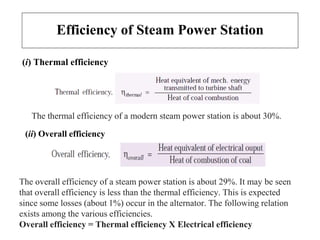

- Parameters that determine efficiency of steam power plants.

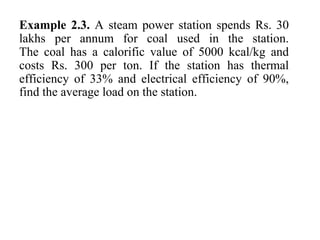

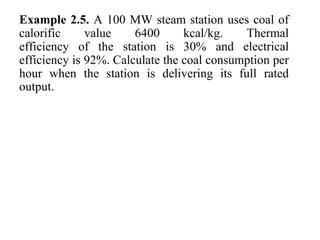

- Examples of calculations related to efficiency, coal consumption and costs.