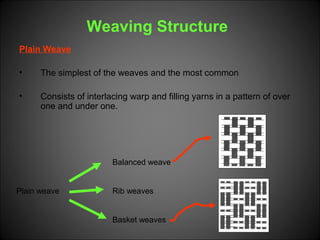

The document discusses weaving technology and processes. It begins with definitions of weaving and the basic components of warp and weft yarns. It then outlines several key steps in preparing yarns for weaving including warping, sizing, drawing-in, and tying-in. The core principles of weaving are explained as shedding, picking, and beating-up yarns. Basic mechanisms for controlling warp and cloth movement are also covered. Different weaving structures like plain, twill, and satin weaves are defined. Finally, methods for analyzing woven fabrics are presented such as warp/weft density, count, weight, crimp, and take up.

![% Crimp, %c = [(ly – lfab) / lfab] x 100

Crimp (waviness of yarns)

Fabric Take up

% Take up, %t = [(ly – lfab) / ly] x 100](https://image.slidesharecdn.com/weavingpptbyaumi-151129194316-lva1-app6892/85/Weaving-ppt-by-aumi-27-320.jpg)