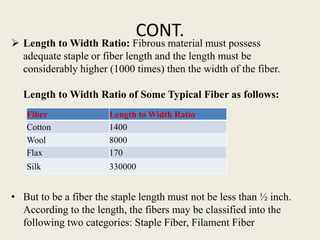

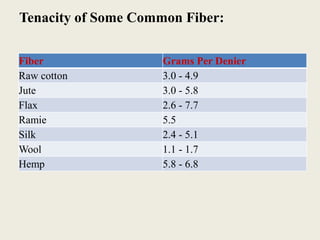

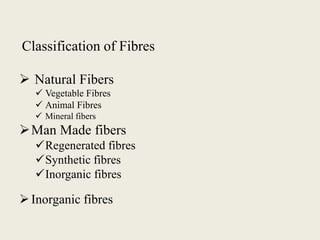

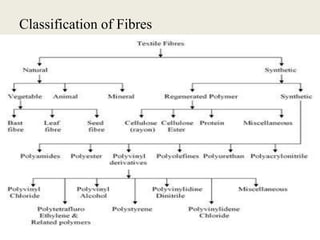

The document provides an introduction to textile fibers, defining key terms such as fiber, fabric, and apparel, and explaining the essential characteristics and classifications of different fiber types. It discusses both natural and man-made fibers, their properties, and the process of converting them into yarn and fabric. Additionally, it highlights the importance of elasticity, strength, and other attributes that determine the suitability of fibers for textile applications.