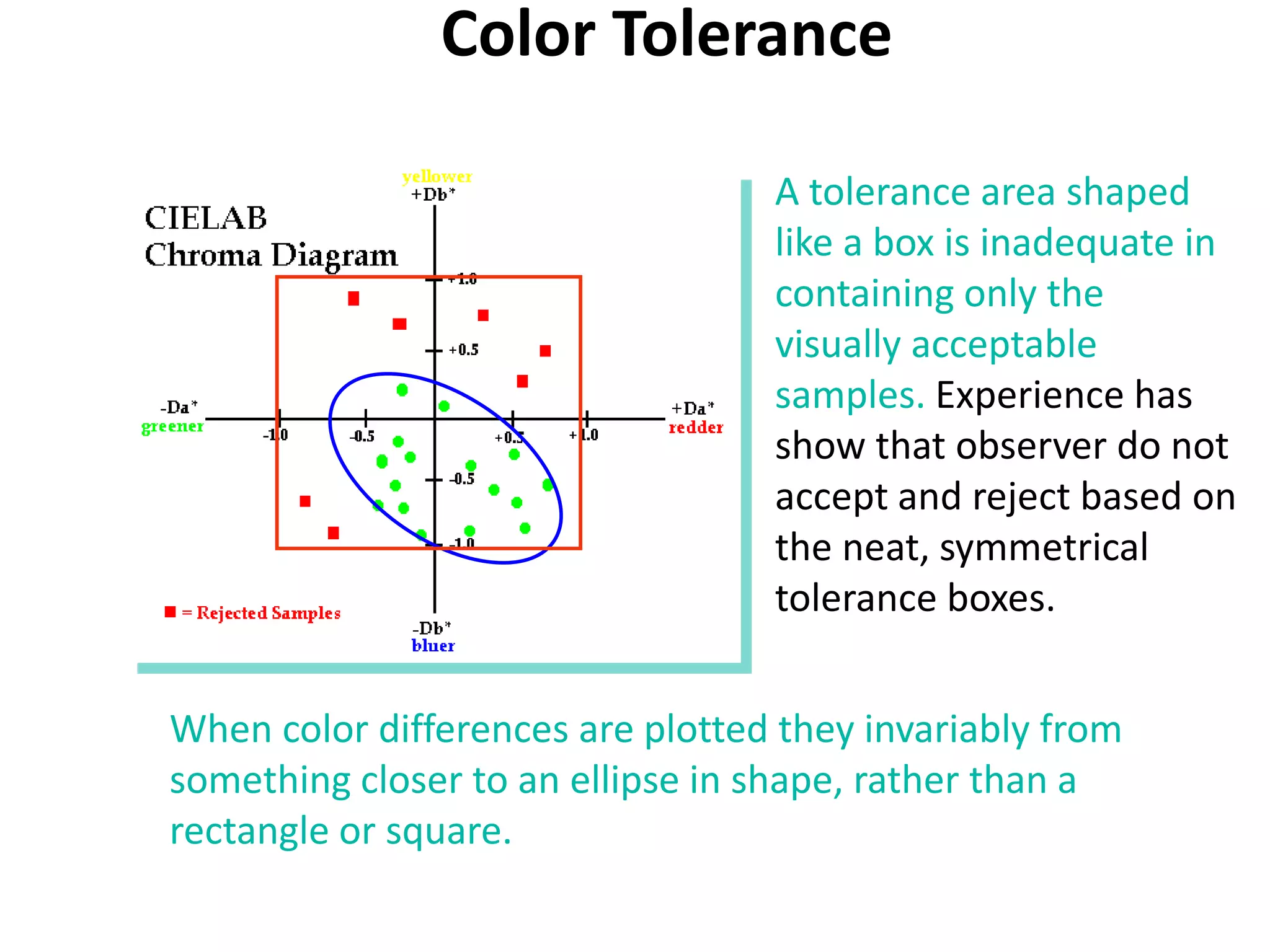

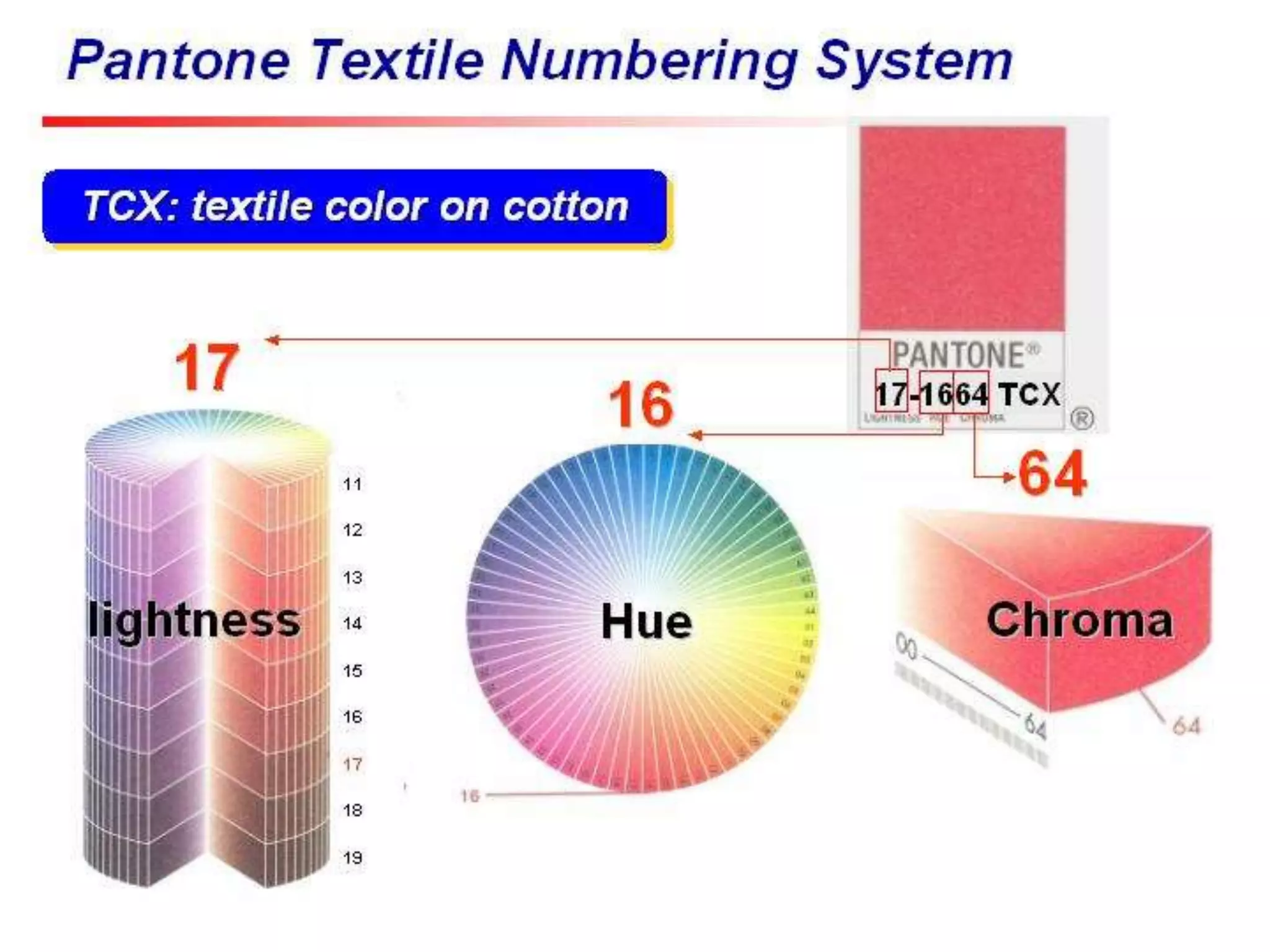

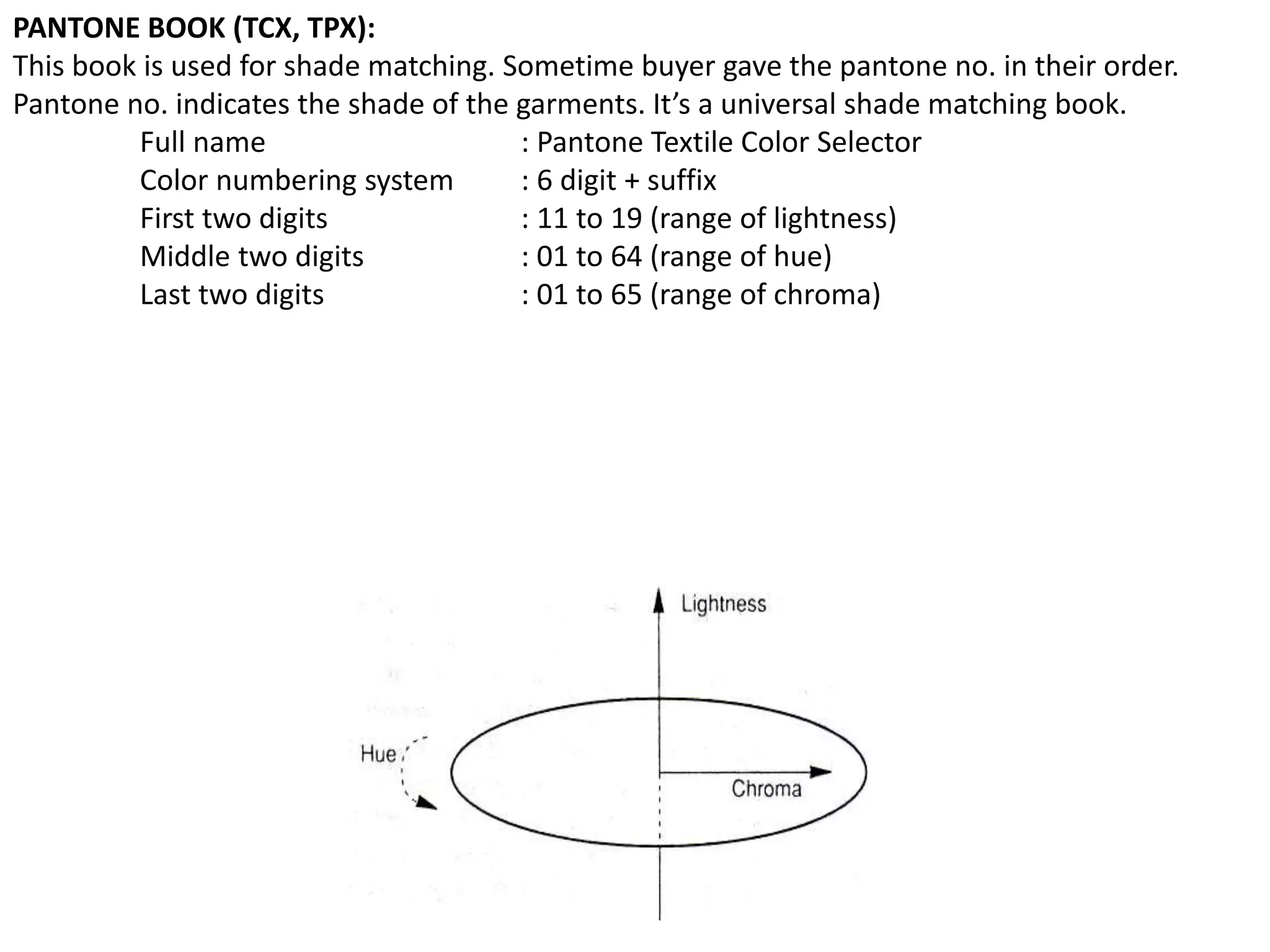

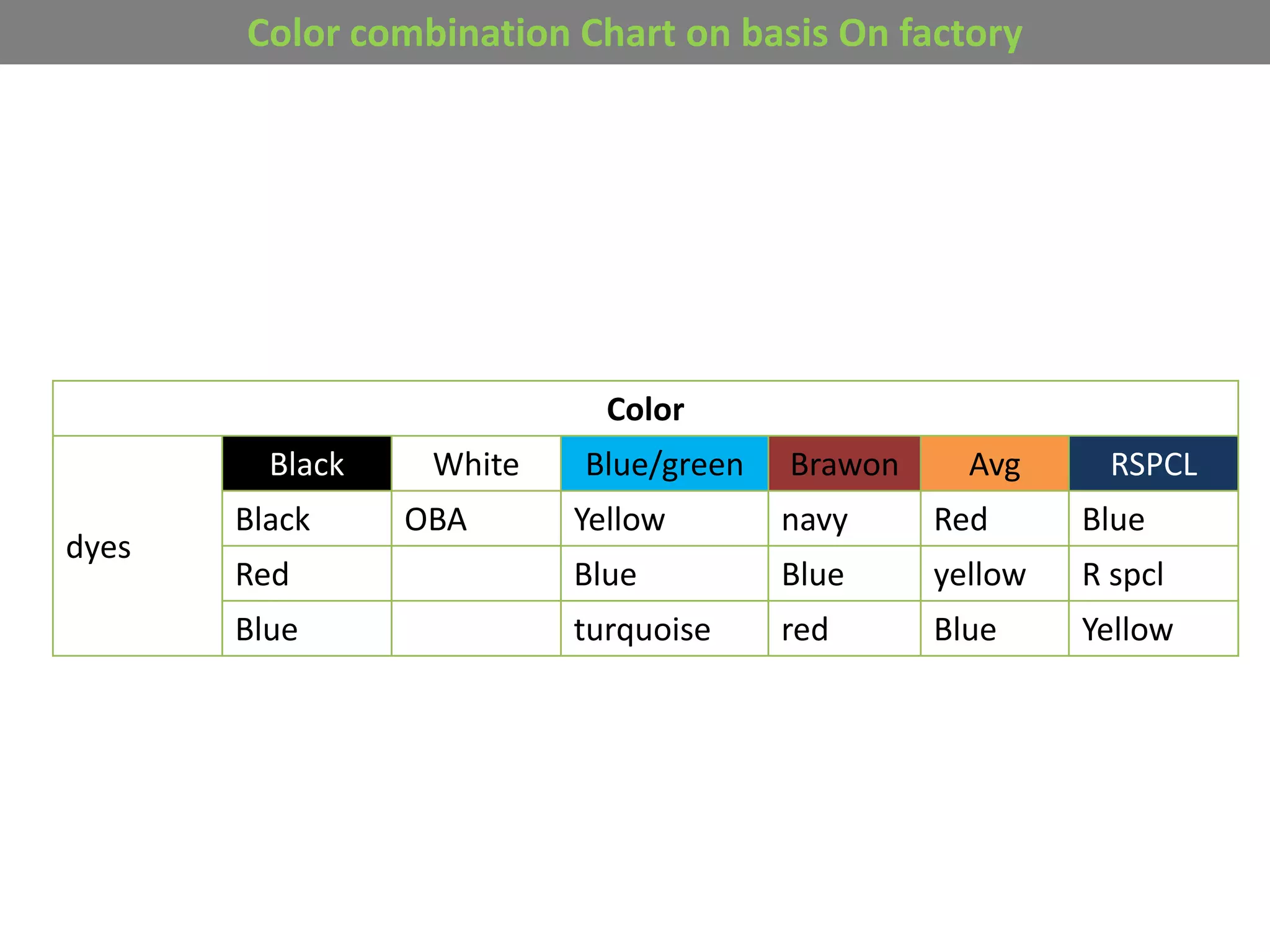

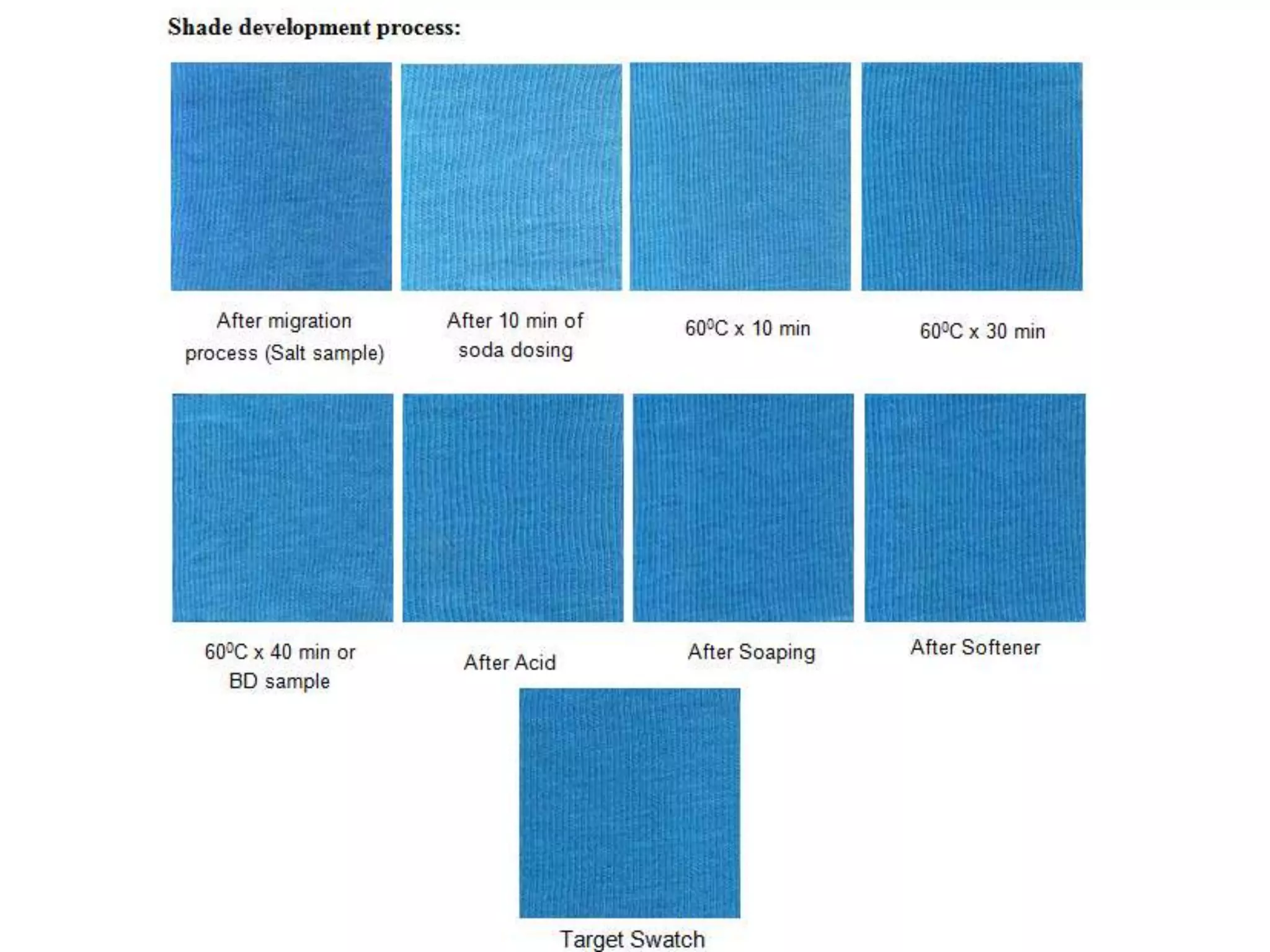

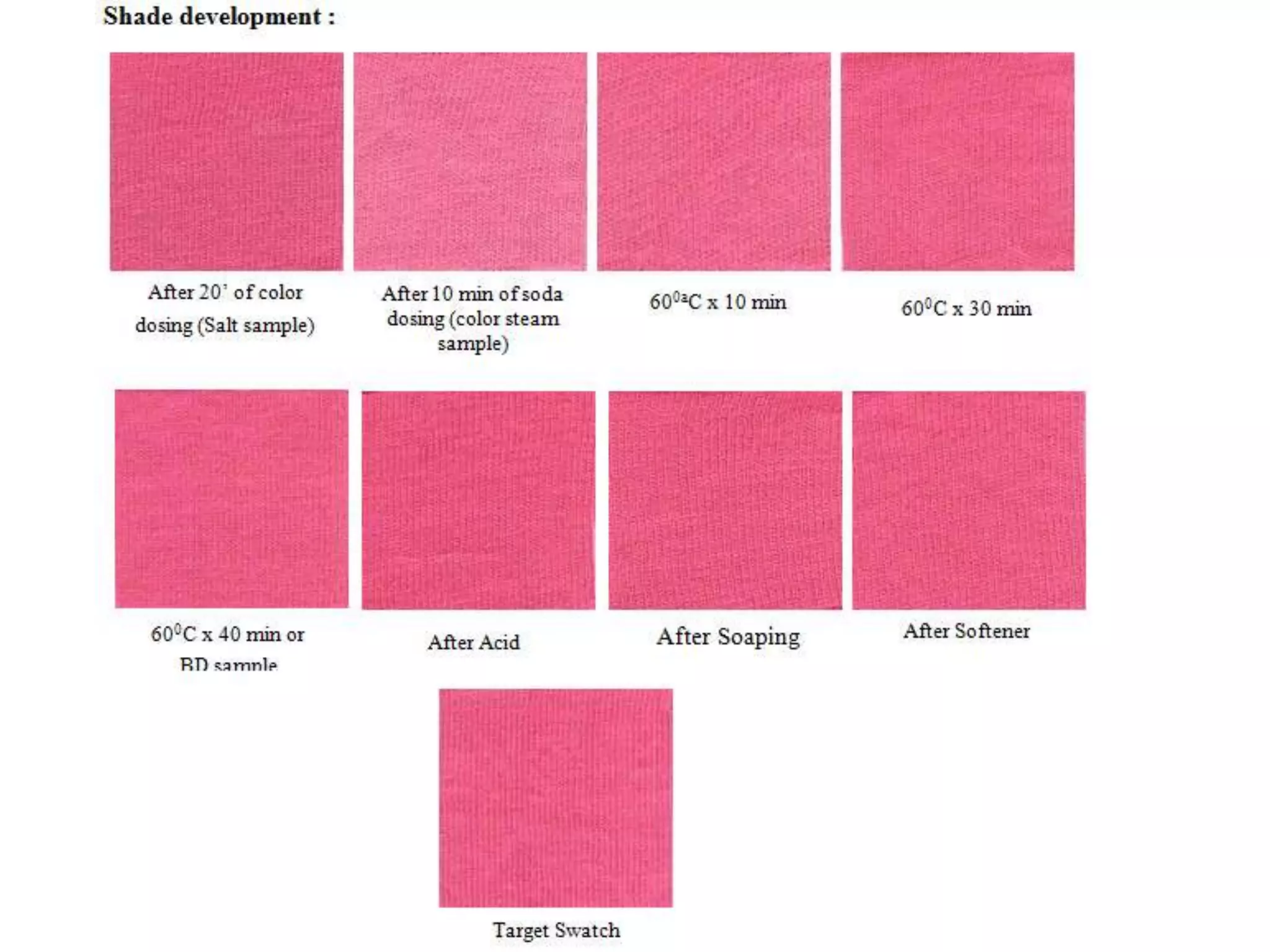

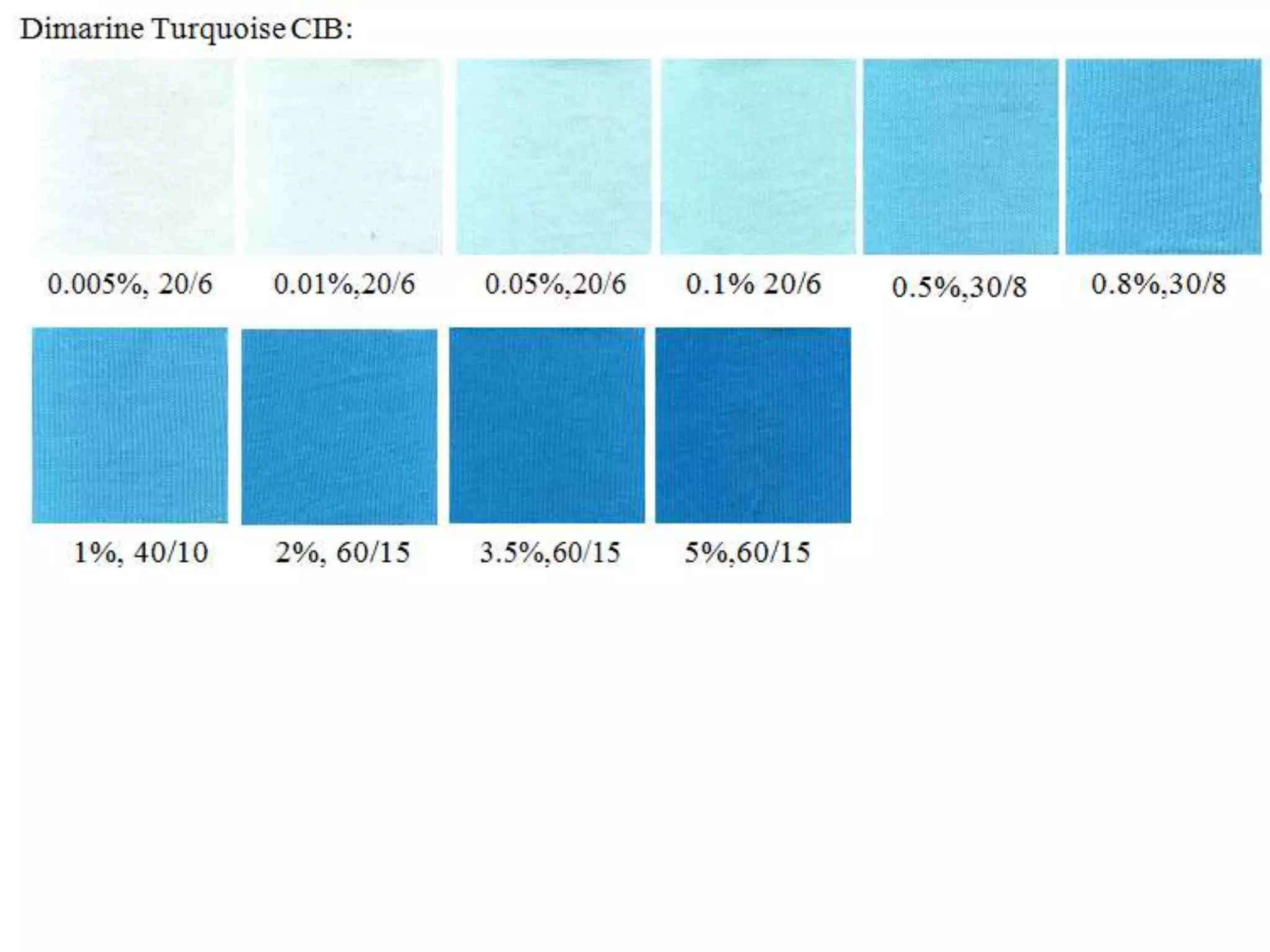

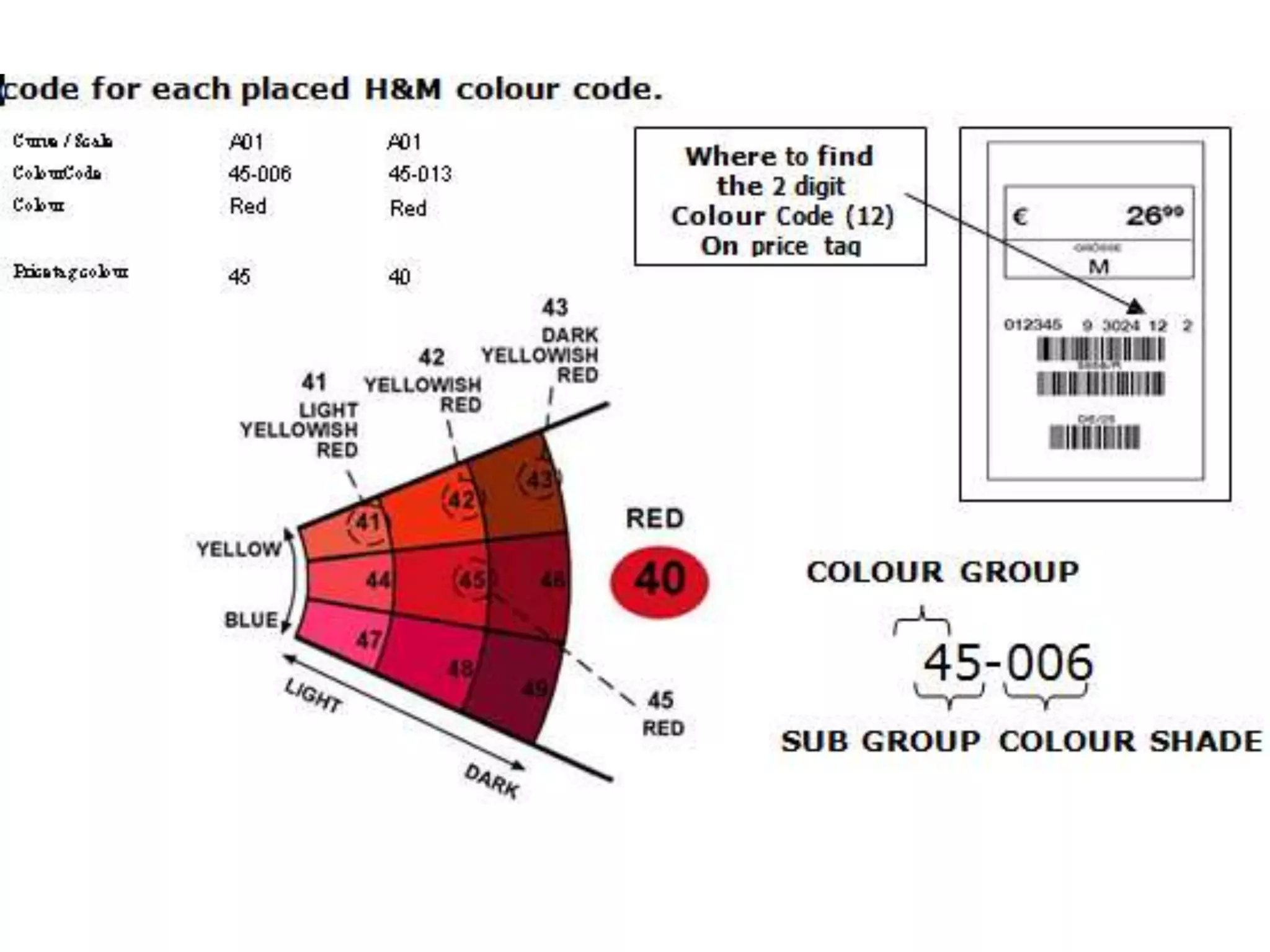

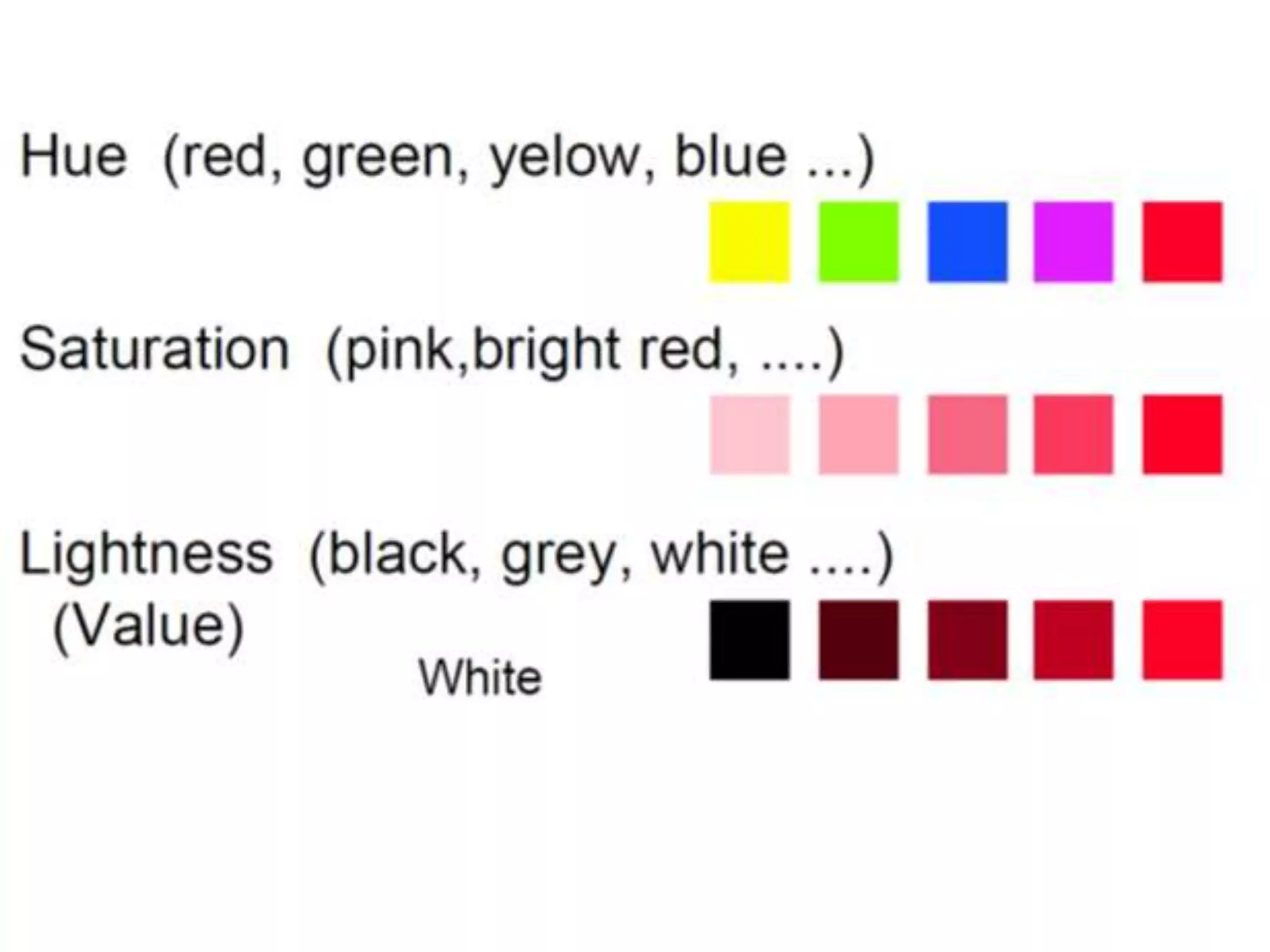

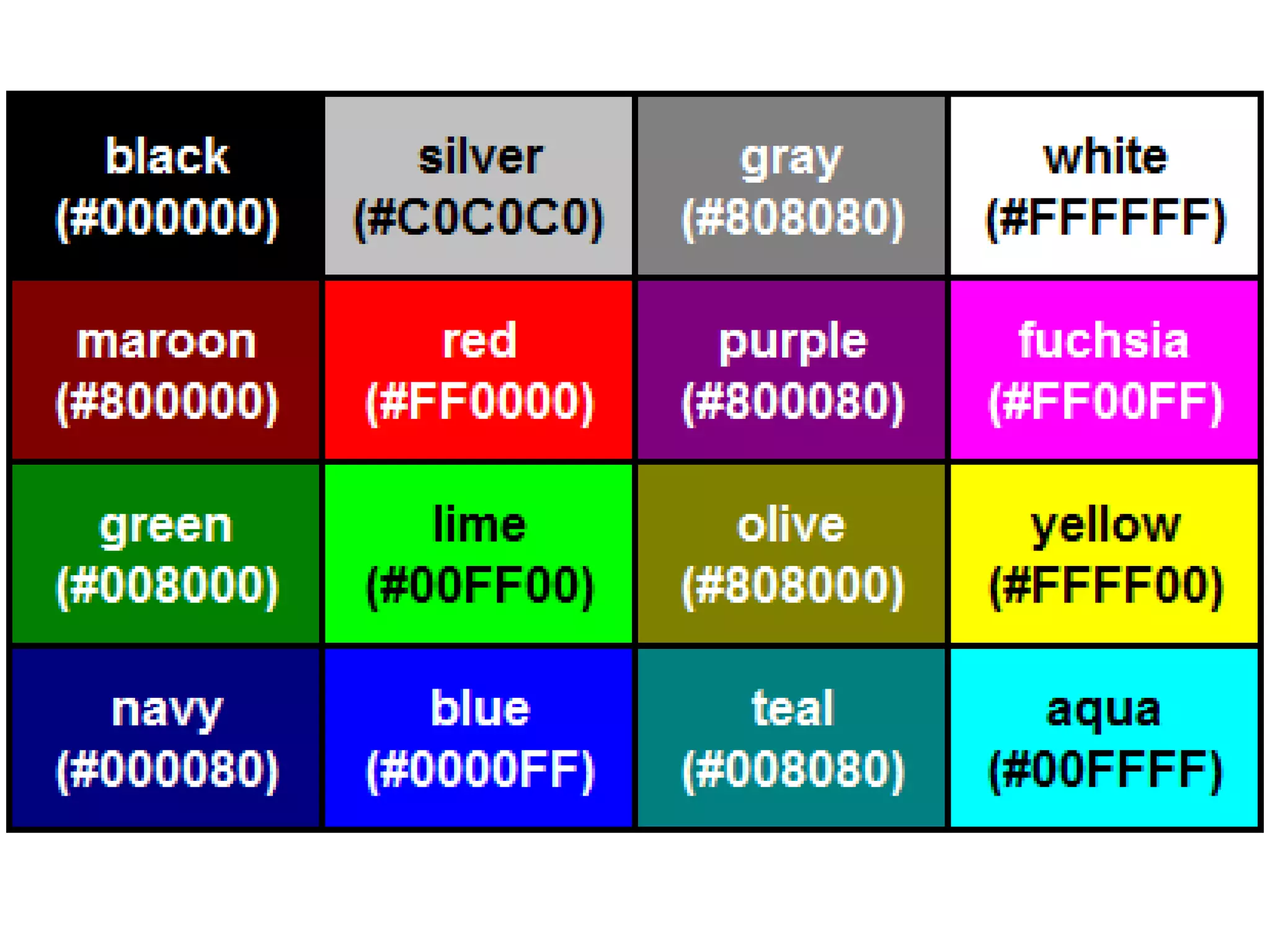

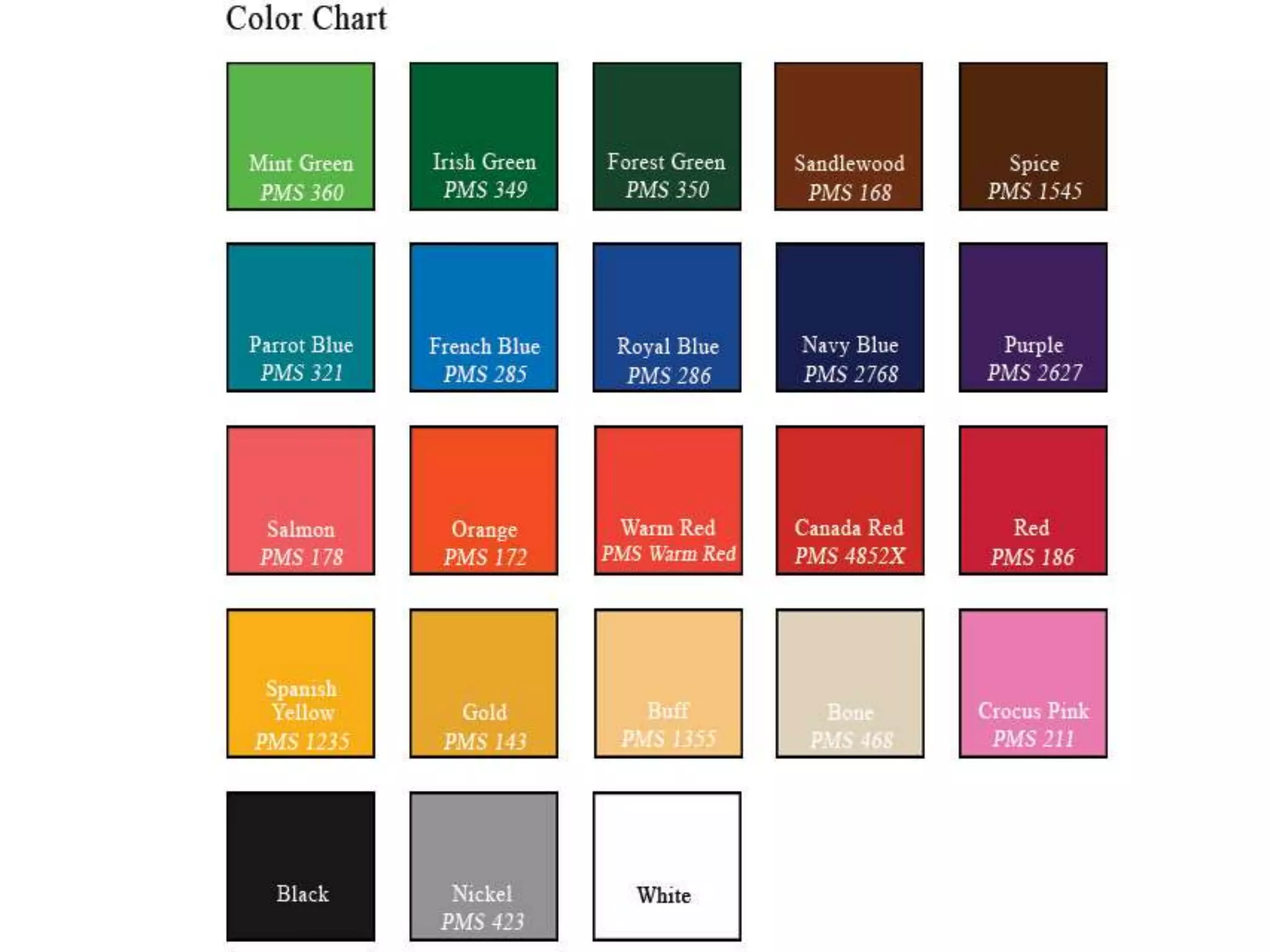

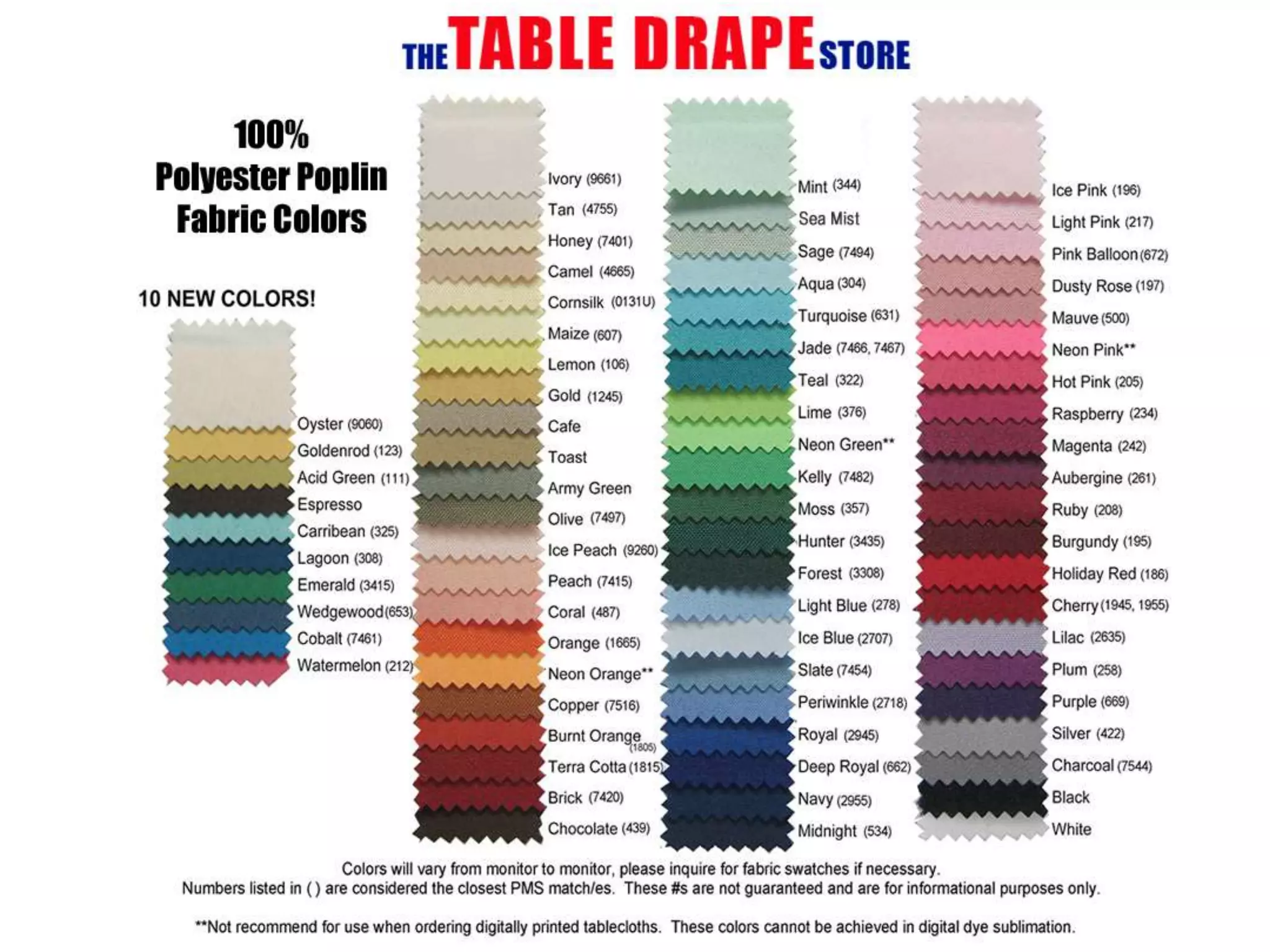

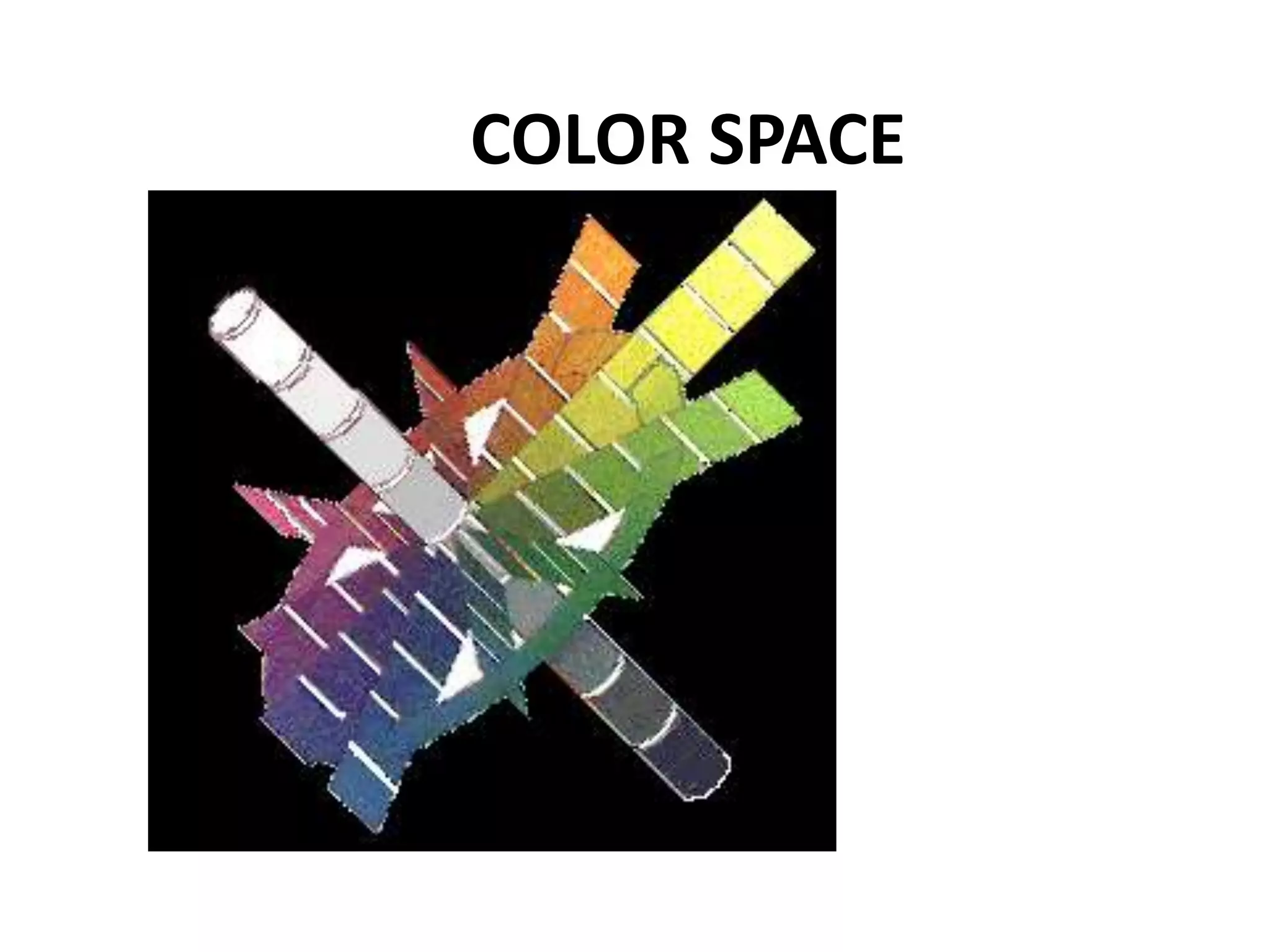

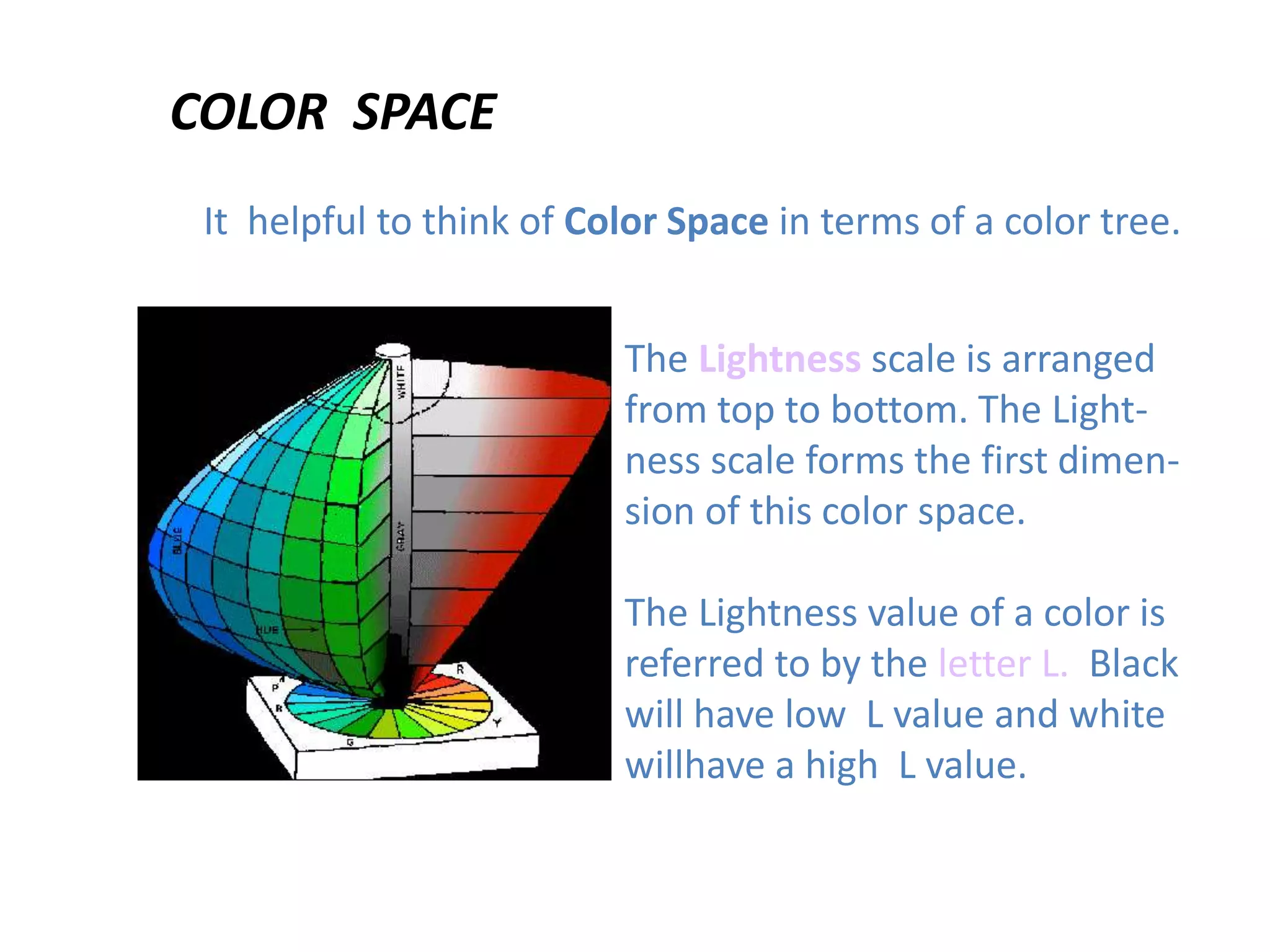

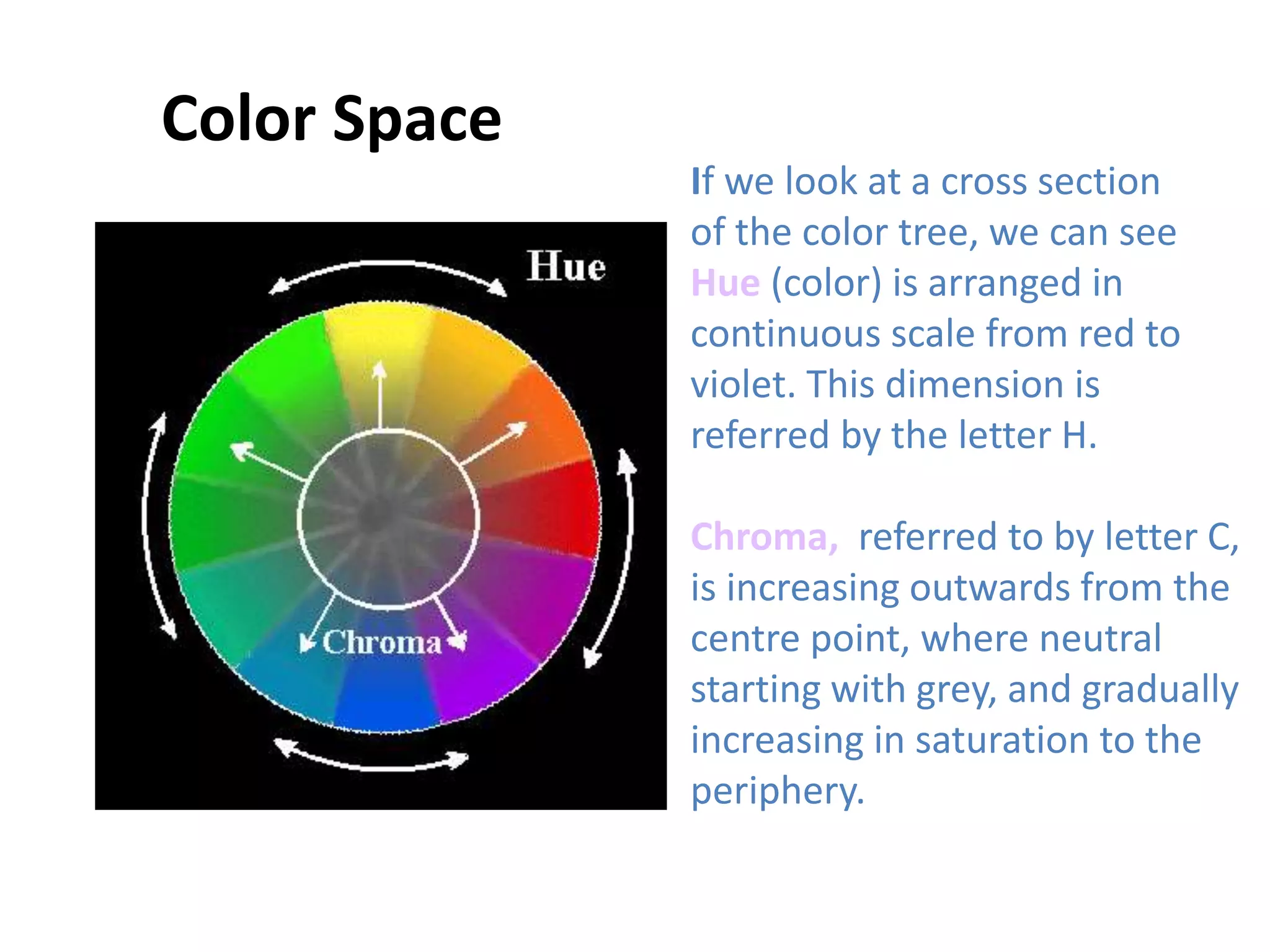

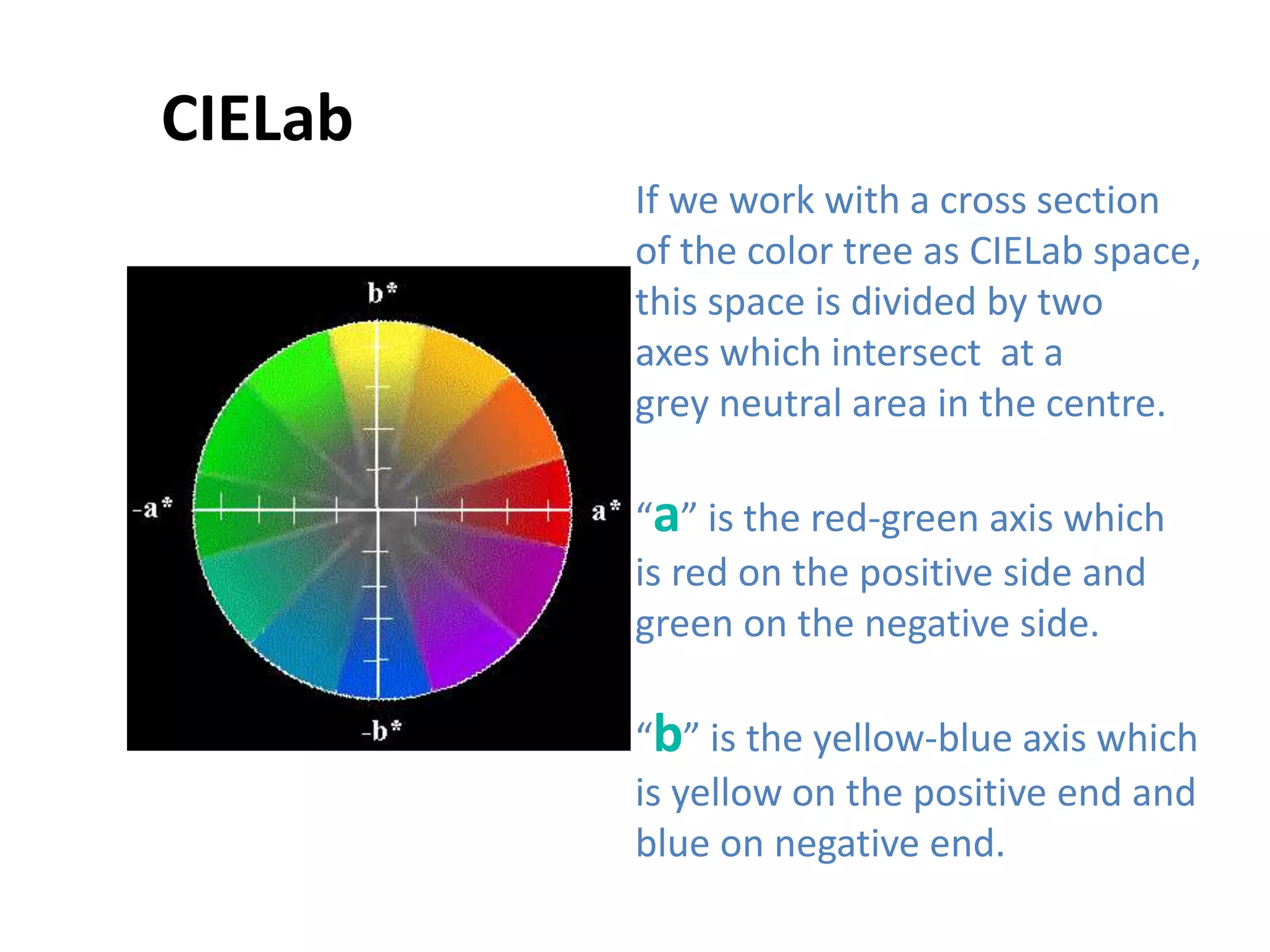

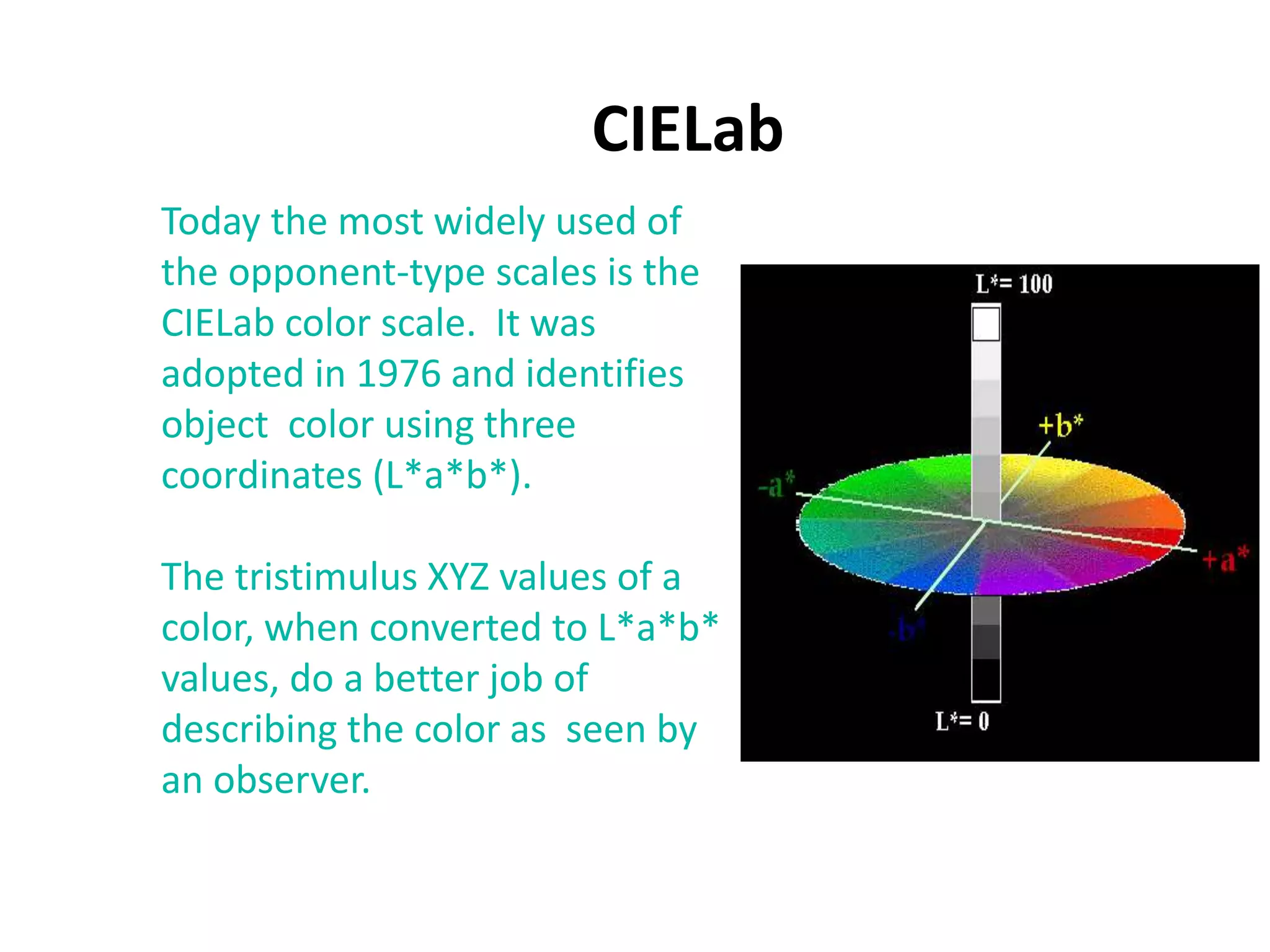

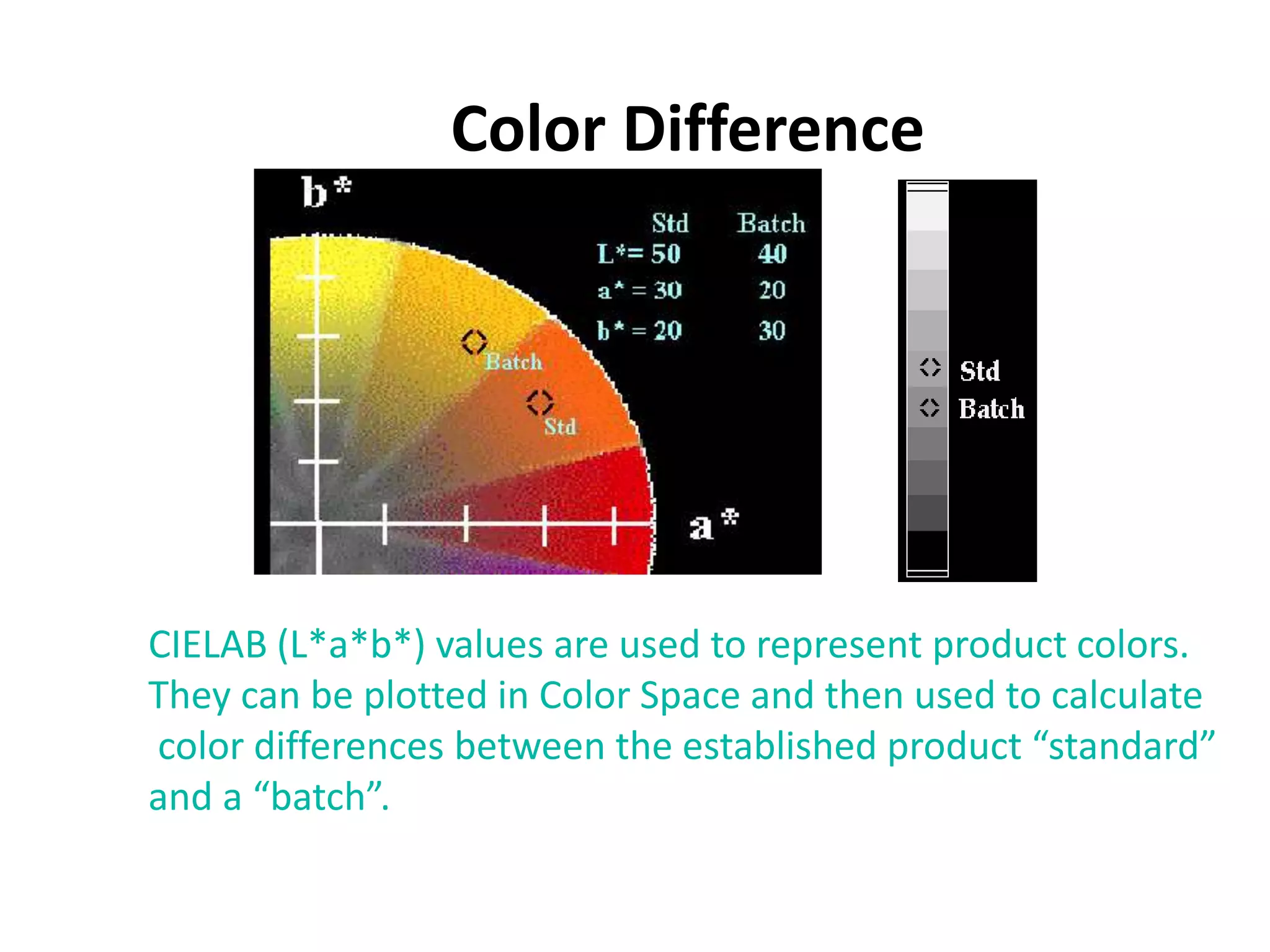

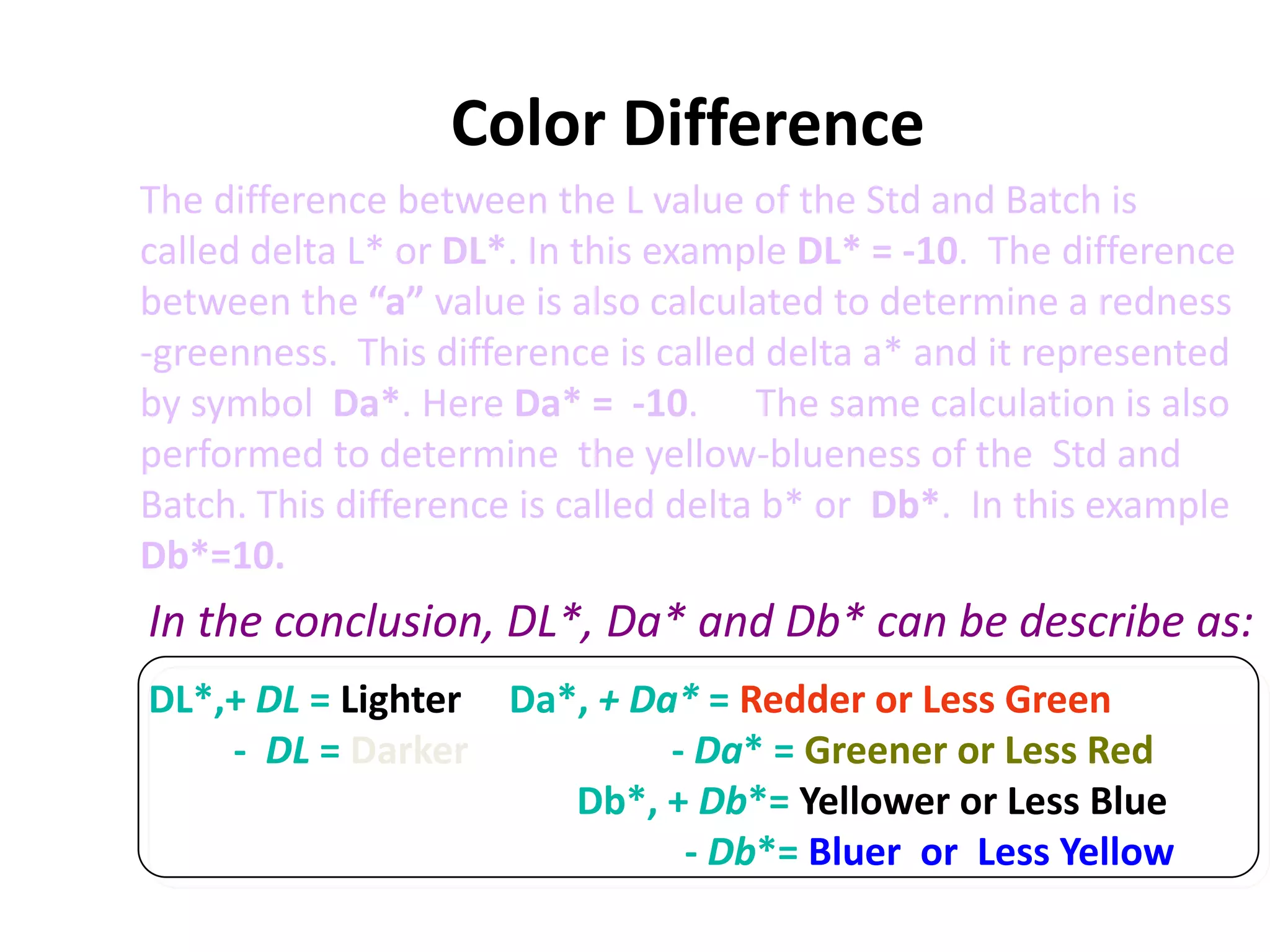

The document provides an overview of textile coloration measurement, outlining color classes and the Pantone color matching system. It explains the concept of color space using the CIELAB model, detailing metrics for hue, lightness, and chroma, and describes methods to calculate color differences between standards and batches. Additionally, it emphasizes the importance of establishing color tolerance areas for quality control in production, suggesting that these areas are more accurately represented by ellipses rather than rectangles.

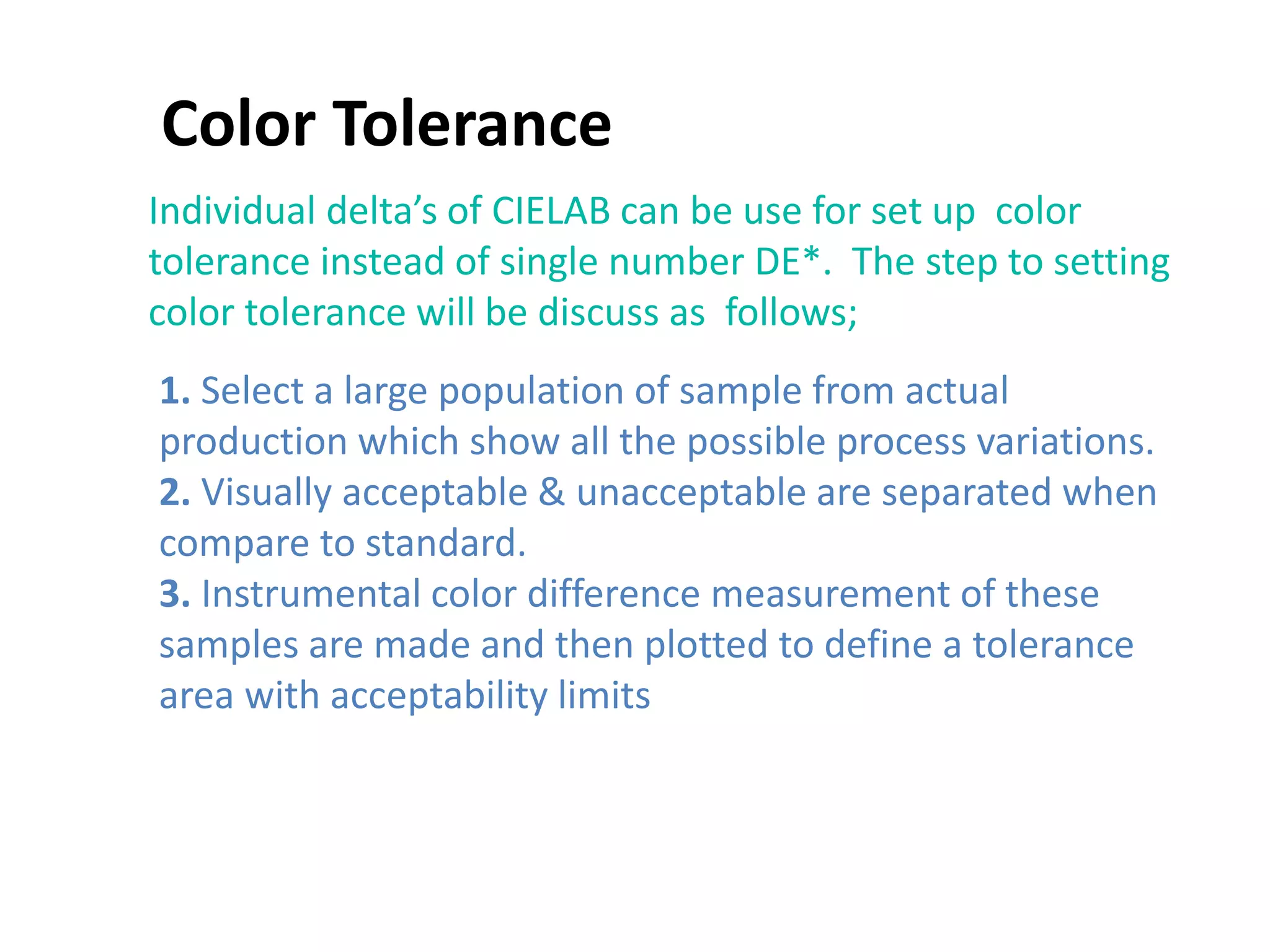

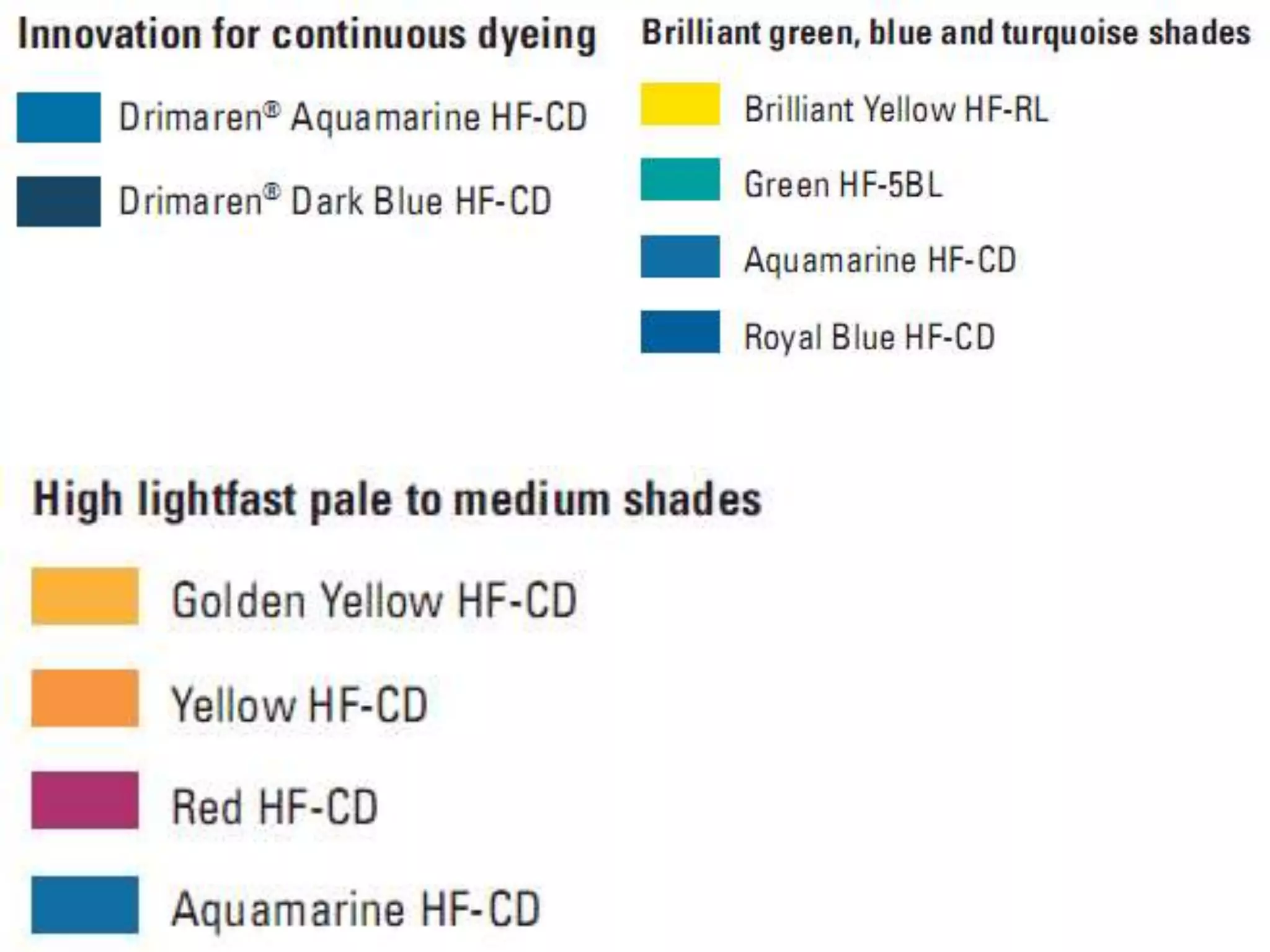

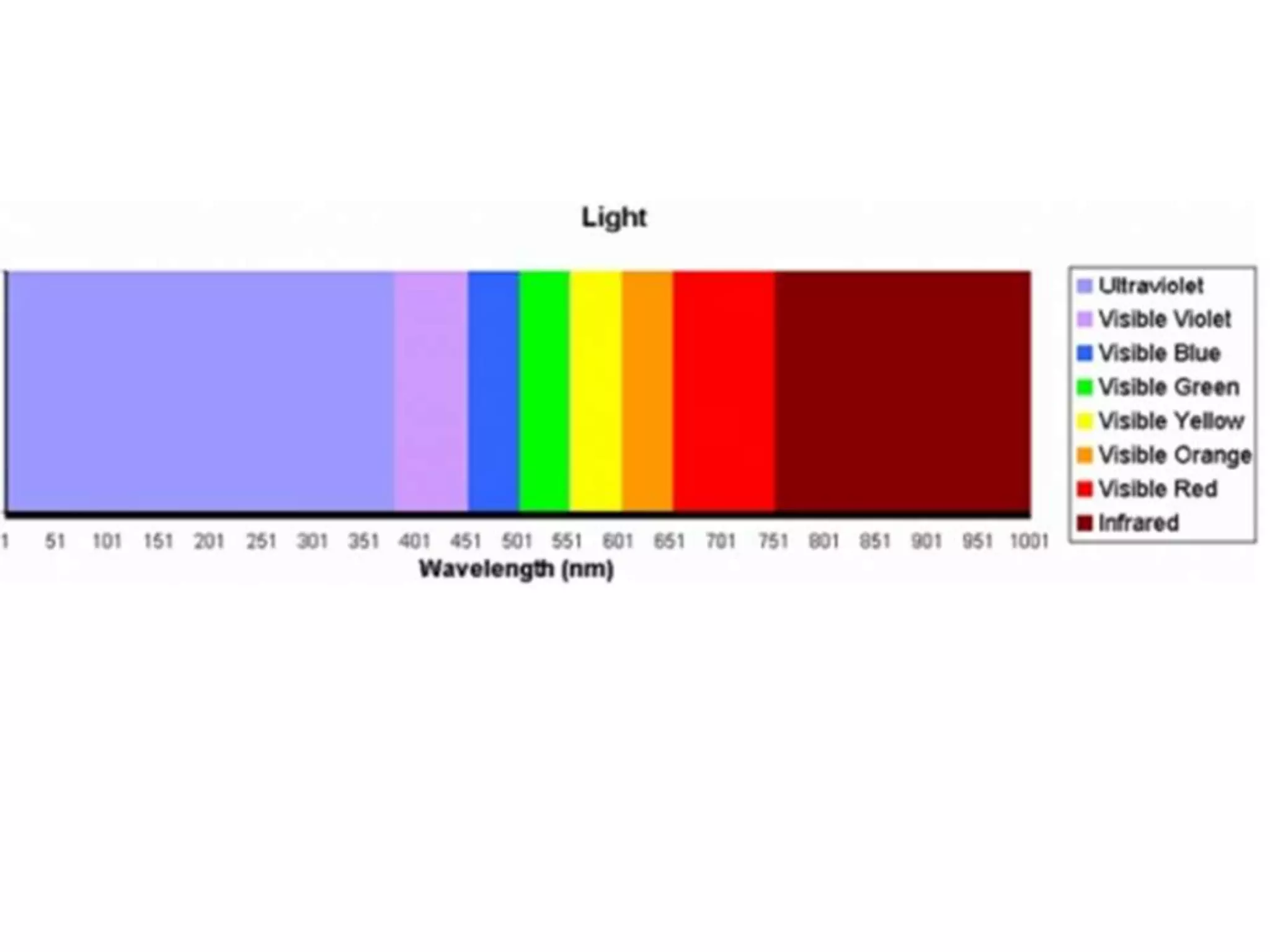

![Color Difference

If we draw the line from

intersection of “a” and ”b”

axis to the point represent

the sample, longer the line

is higher the chroma in color.

Chroma difference is referred by

DC*, if DC* is positive a batch has

a higher chroma (stronger); if

negative DC* a batch is weaker

than Std.

As Hue difference is an angular difference, it is not in

CIELAB unit and therefore the preferred component, so

DH* can be calculate by DH*=[(DE)2

-(DL*)2

-(DC*)2

]1/2](https://image.slidesharecdn.com/textilecoloration-140802092025-phpapp02/75/Textile-coloration-43-2048.jpg)

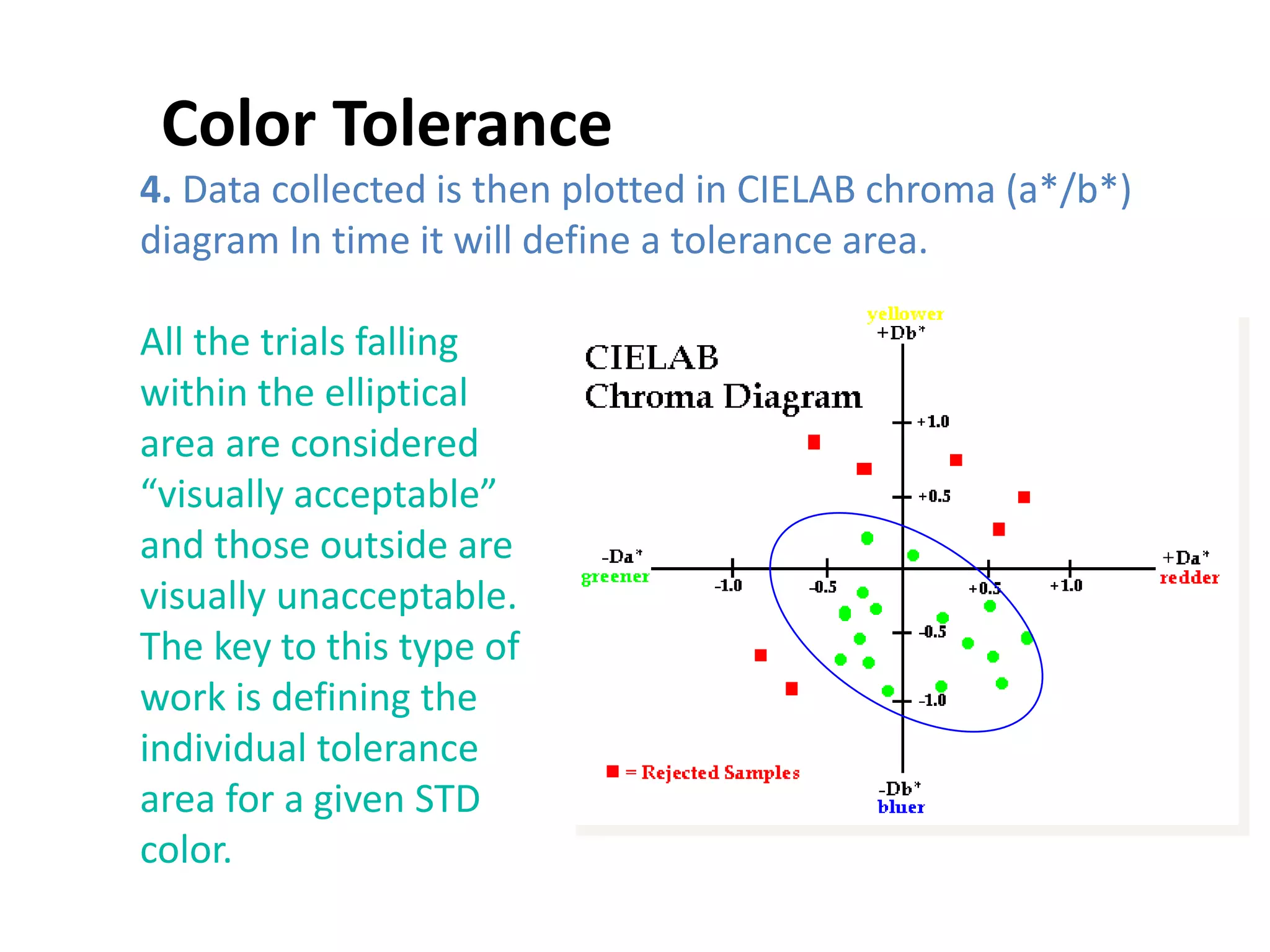

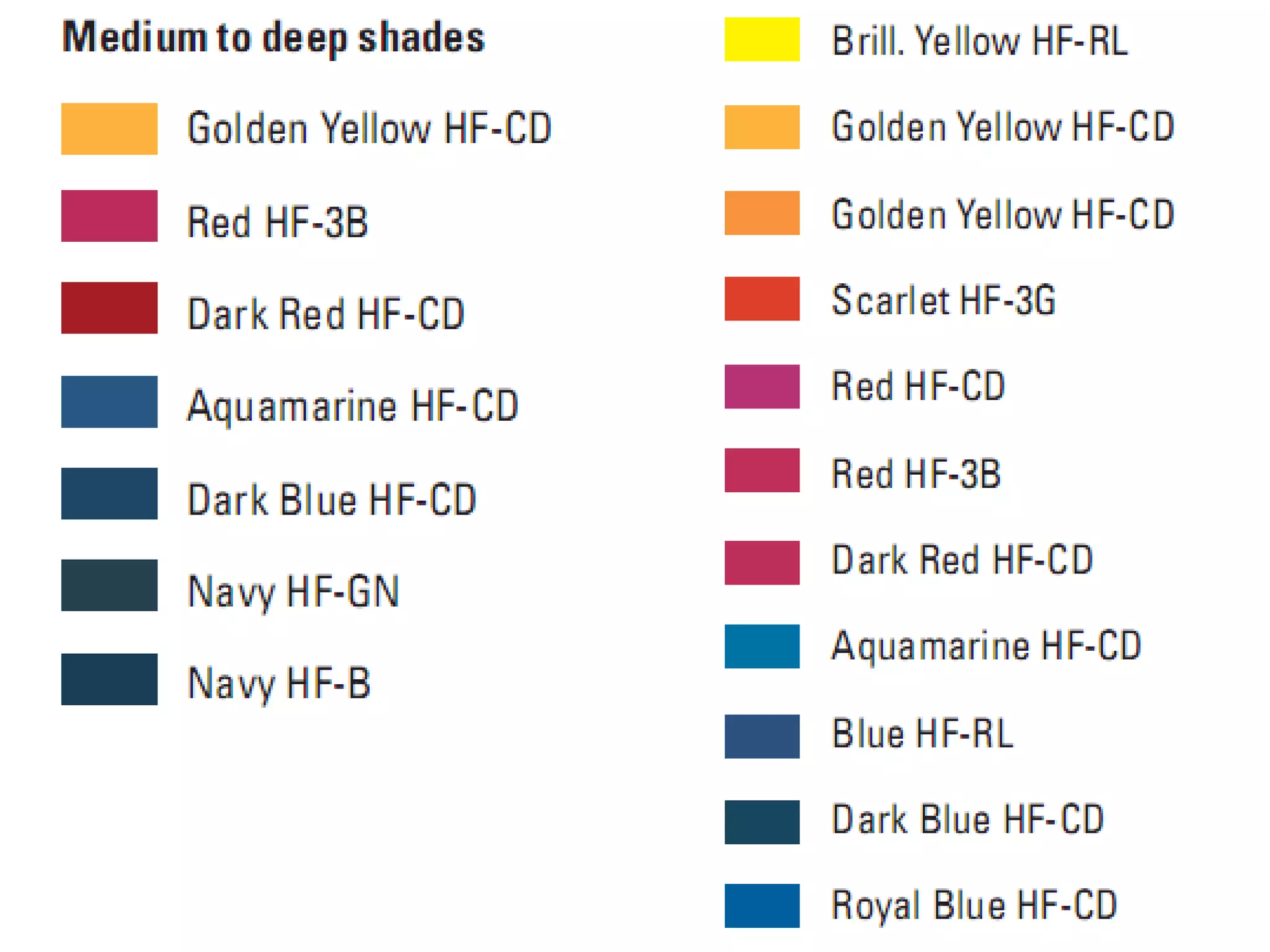

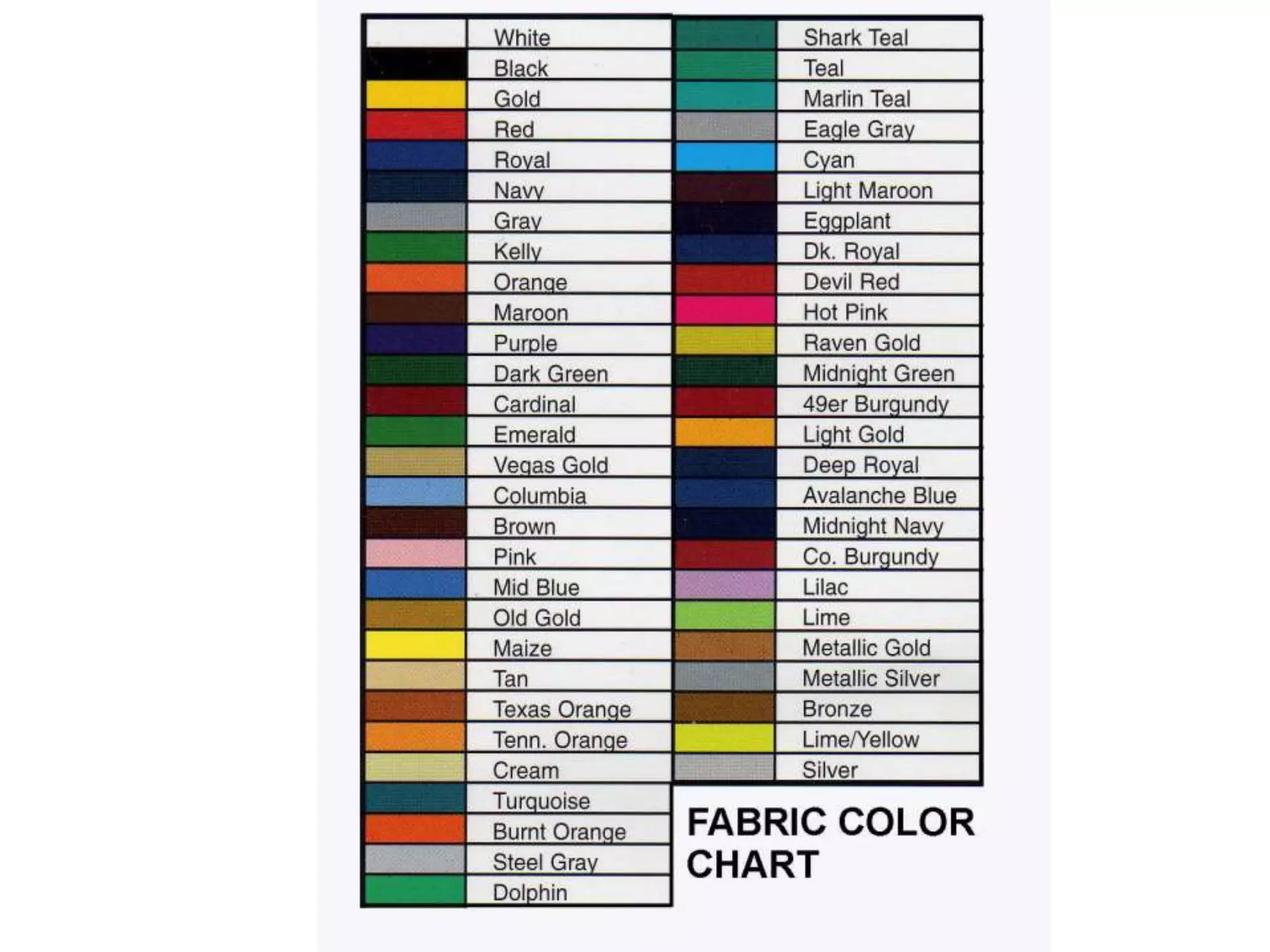

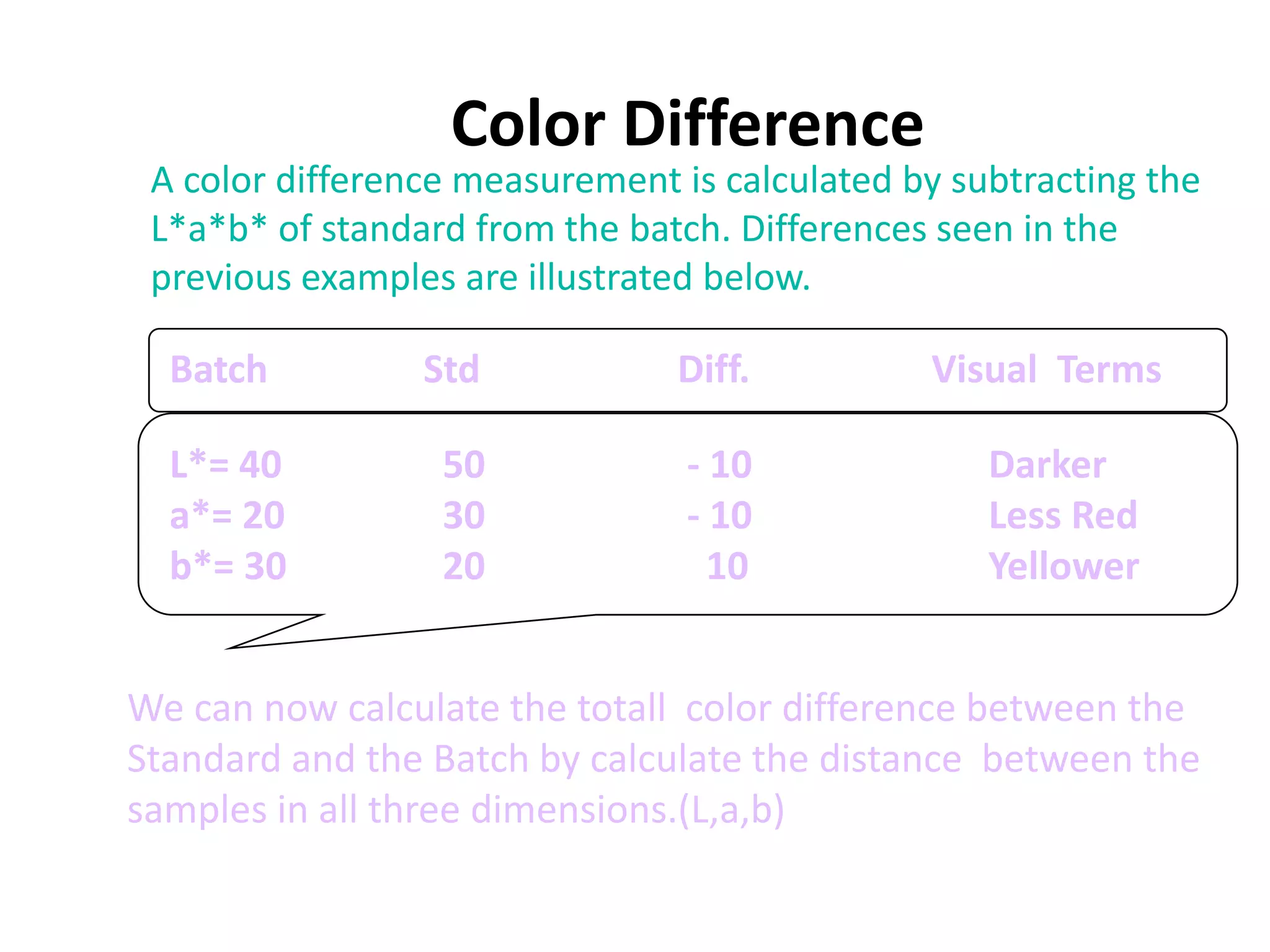

![Total Color Difference

A color difference equation using DL*, Da* and Db* to

calculate the Total Color Difference between Std and the

Batch. This Total Color Difference is called delta E and it

represented by symbol DE*. DE* can be calculated using

this equation;

DE* = [(DL*)2 + (Da*)2 + (Db*)2 ]1/2

With reservation it can be said that color difference DE* >1](https://image.slidesharecdn.com/textilecoloration-140802092025-phpapp02/75/Textile-coloration-44-2048.jpg)