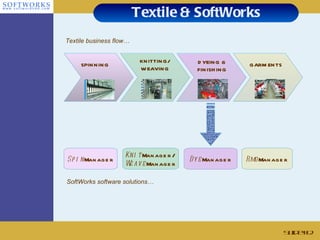

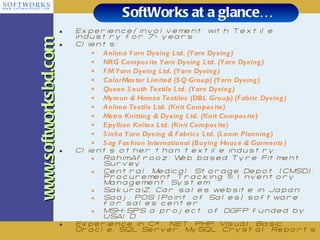

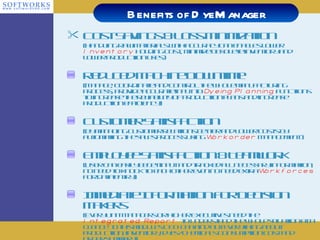

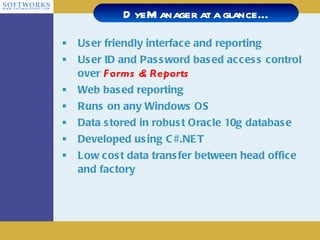

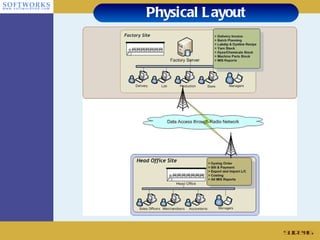

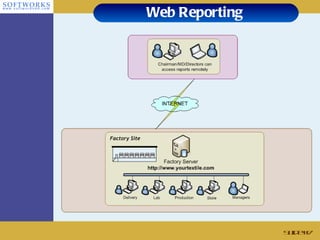

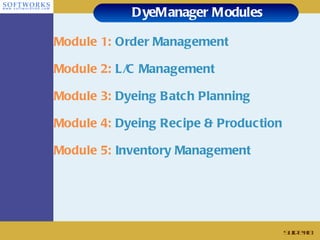

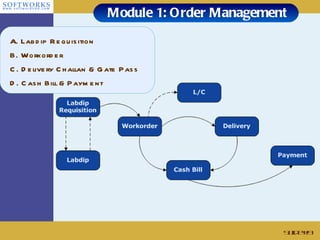

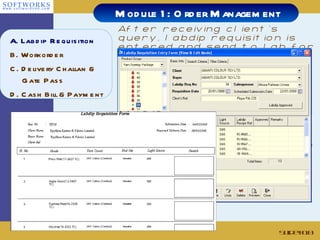

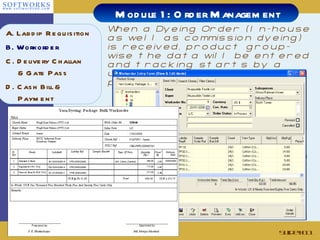

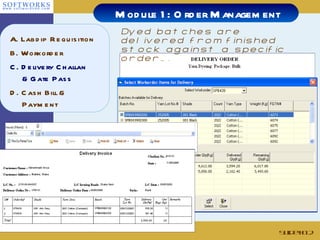

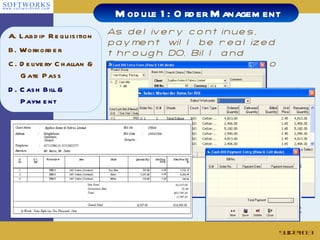

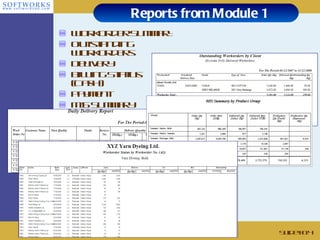

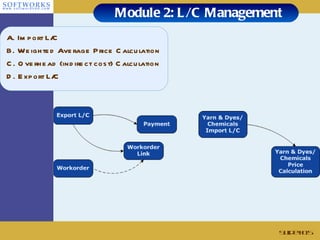

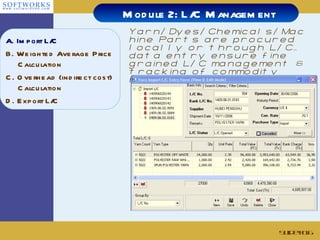

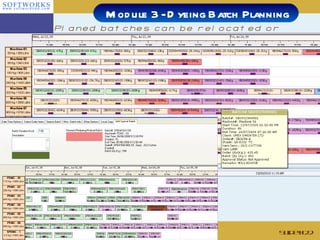

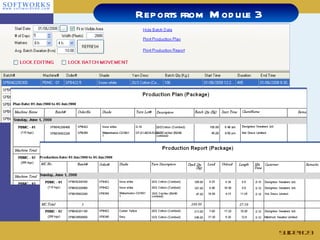

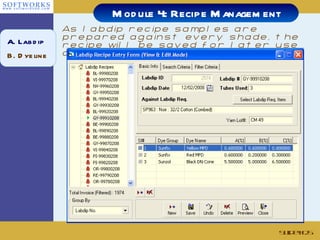

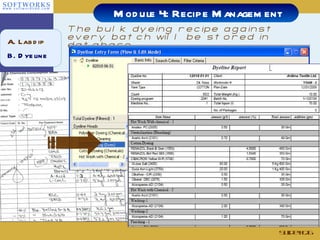

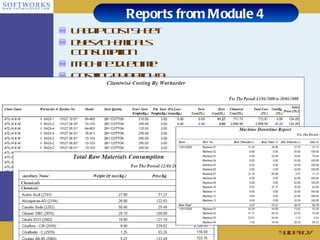

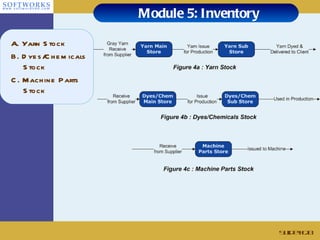

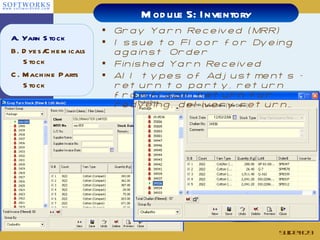

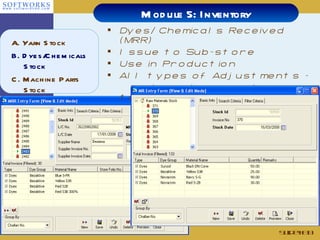

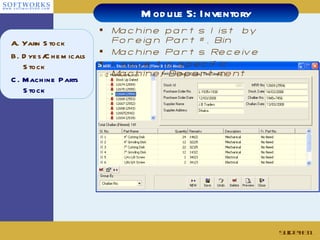

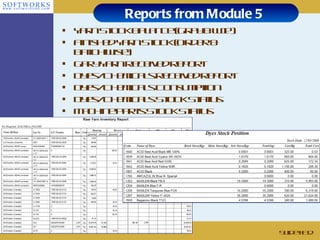

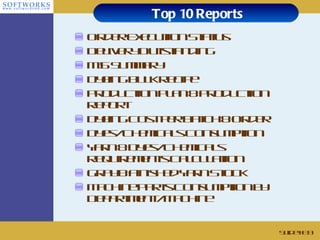

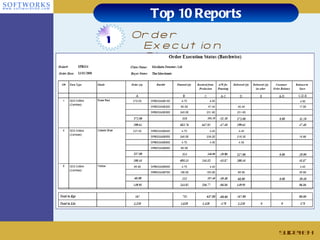

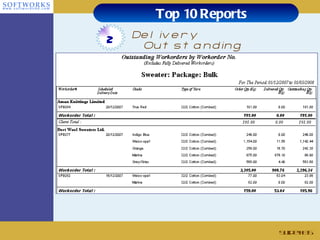

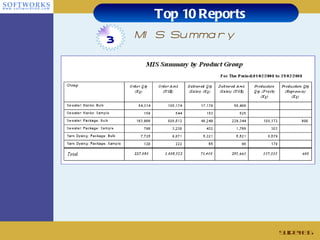

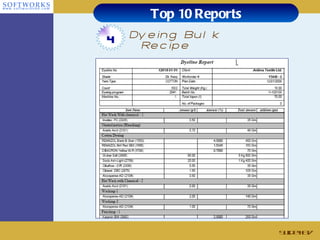

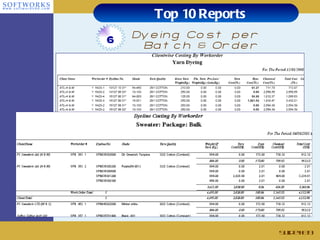

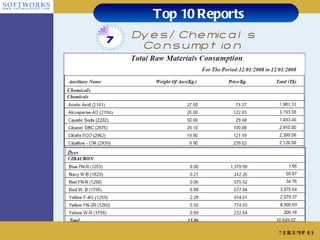

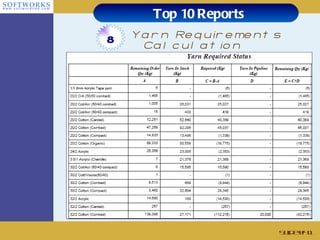

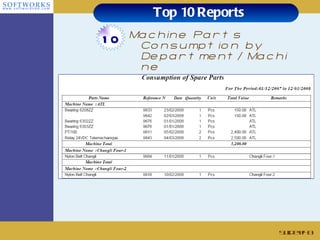

The document describes Dye Manager, a production management software for yarn dyeing businesses. It consists of 5 modules that track orders, inventory, recipes, batch planning, and costs. The software provides integrated reporting to give managers visibility across production. It is implemented for several textile dyeing and knitting companies in Bangladesh to help them reduce costs and optimize operations.