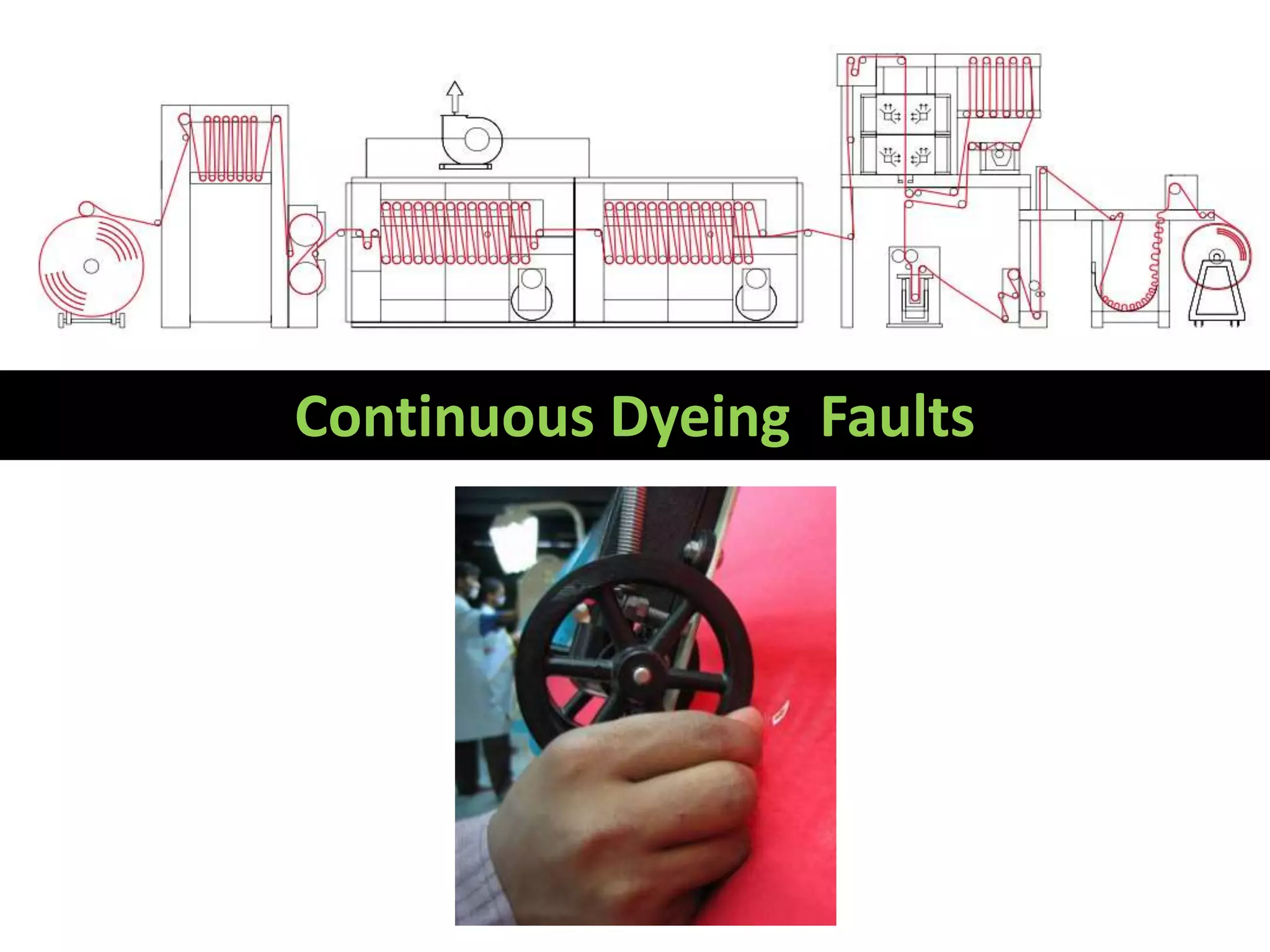

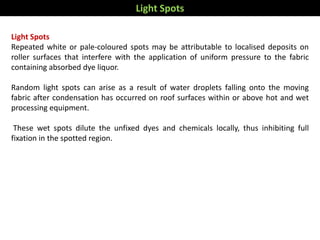

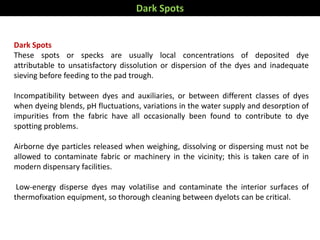

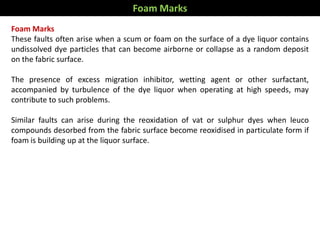

This document discusses common faults that can occur in continuous dyeing processes, including creasing caused by tension issues or roller problems, shade matching faults due to errors in formulation or substrate changes, two-sidedness from uneven drying temperatures, and listing/ending variations across or along the fabric from inconsistencies in preparation or processing. It also describes potential staining faults such as random staining from dye migration during drying, resist marks from inadequate preparation, and spots from deposits or droplets on the fabric or rollers.