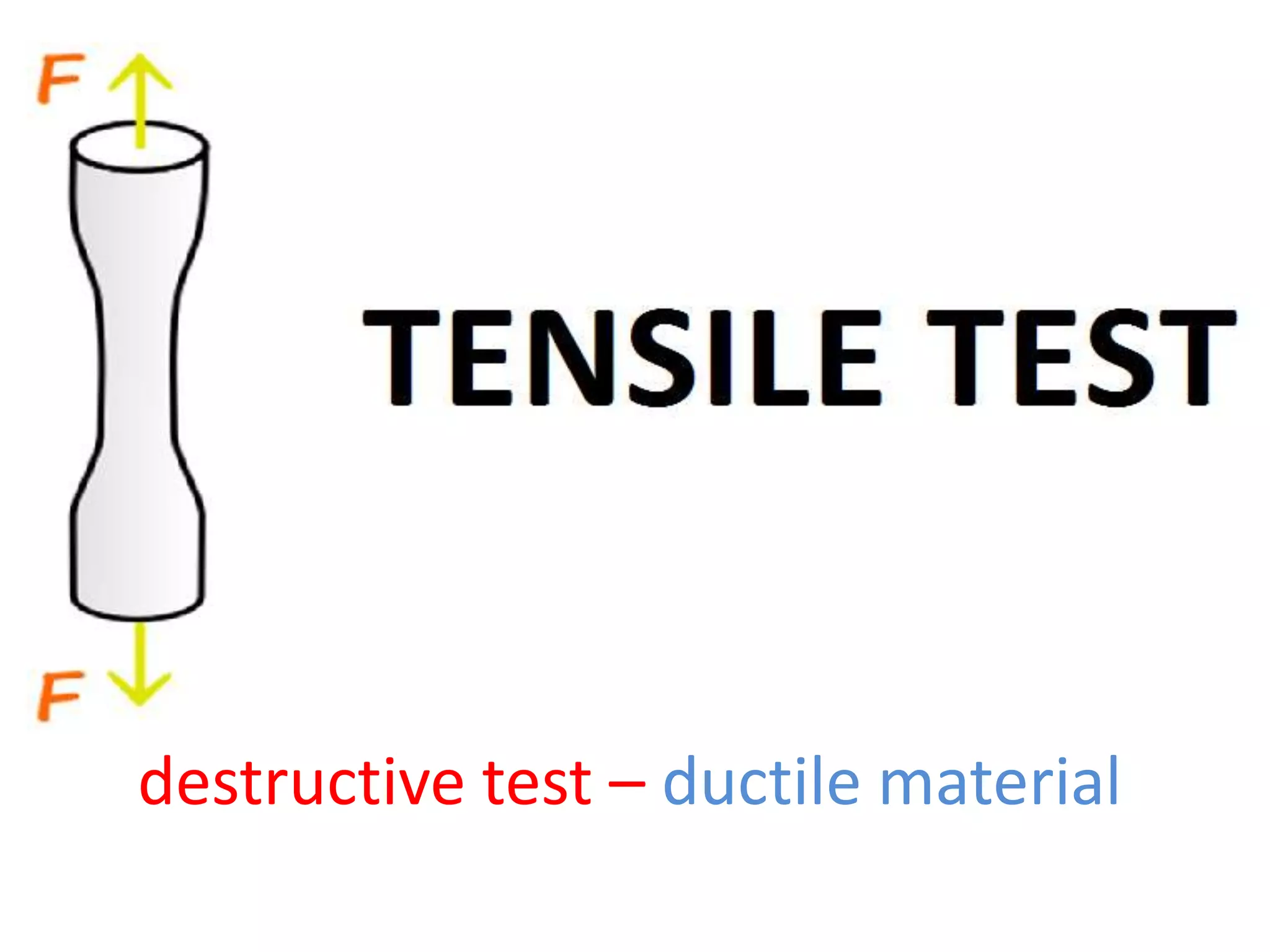

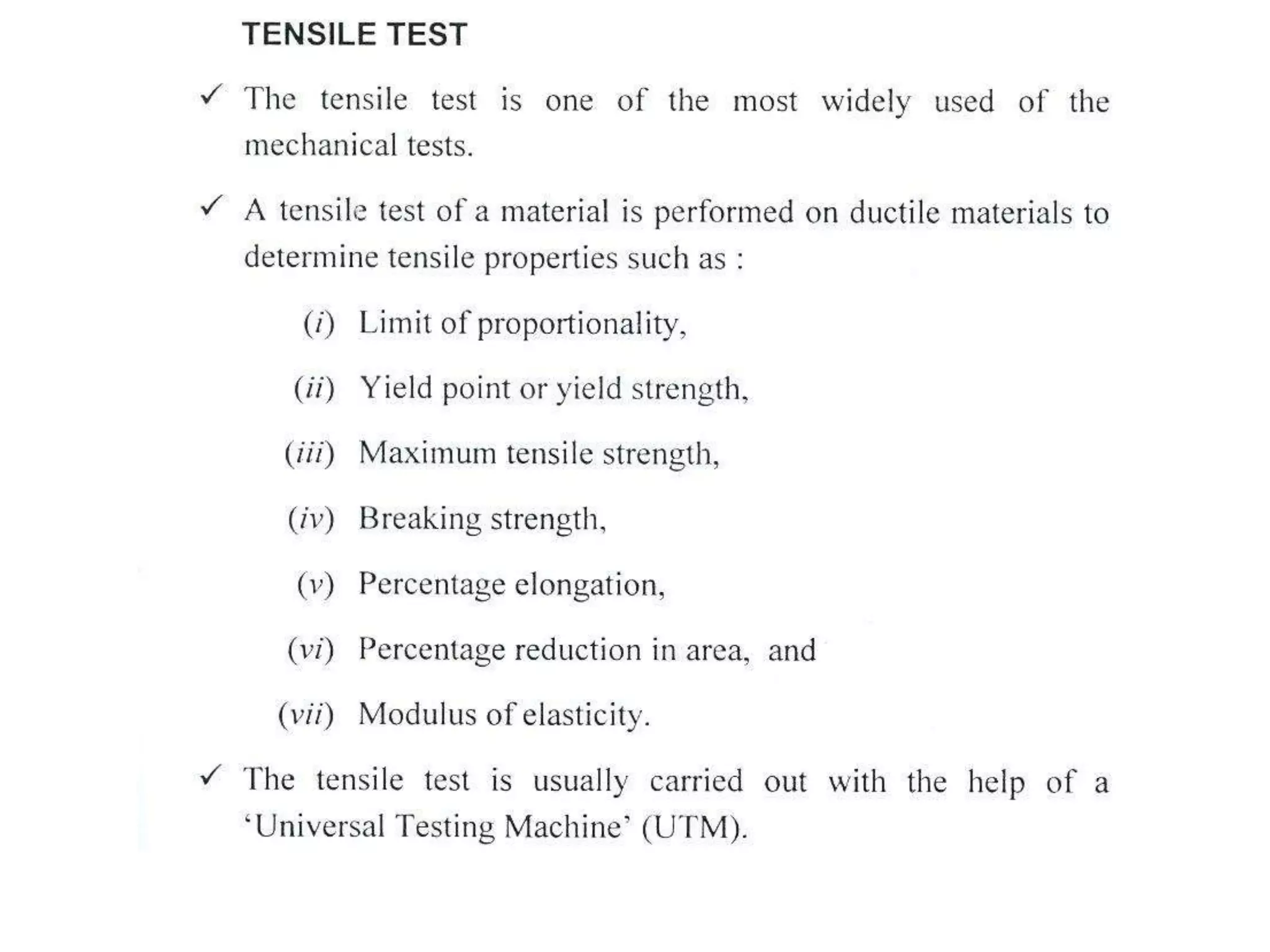

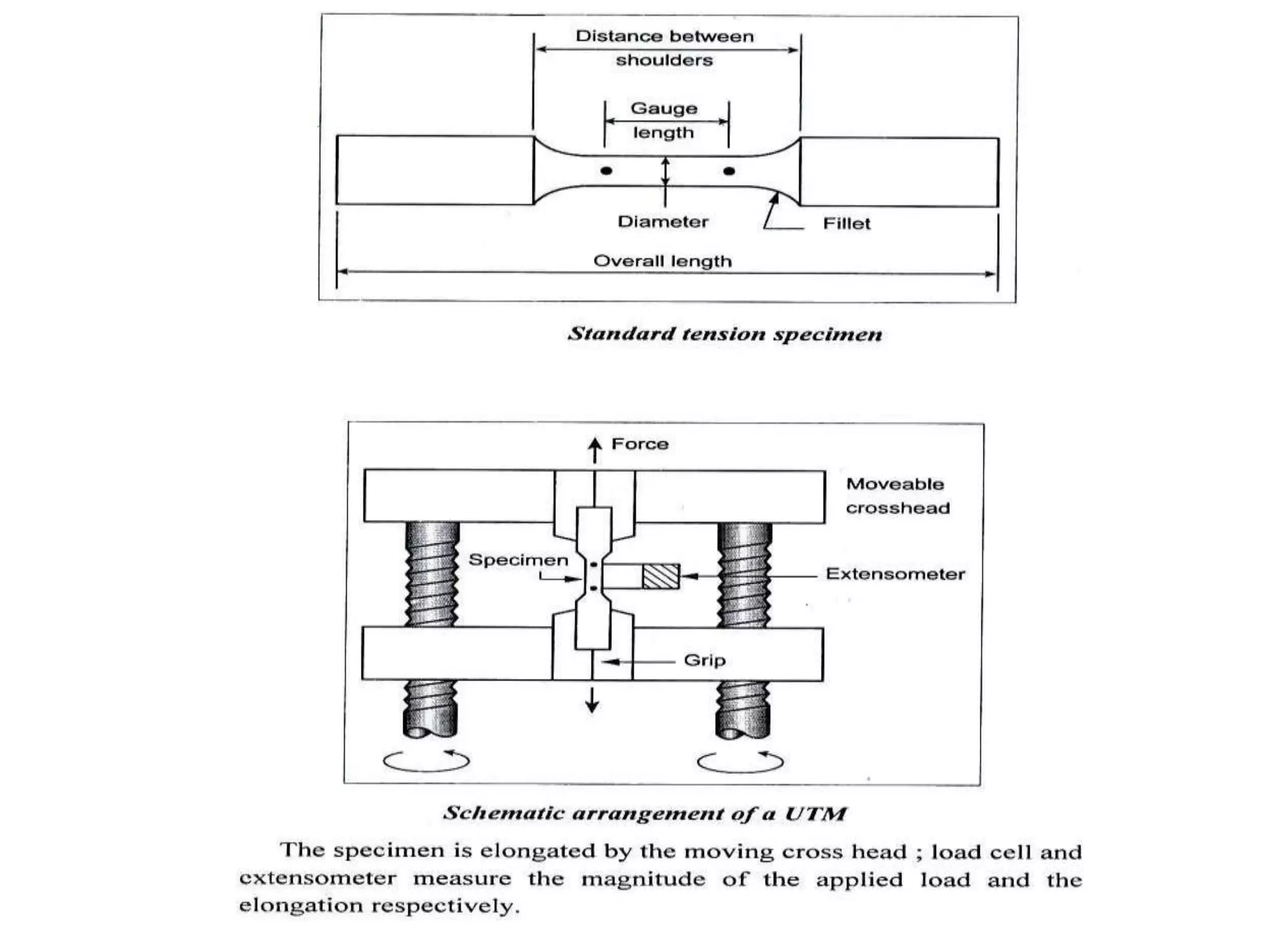

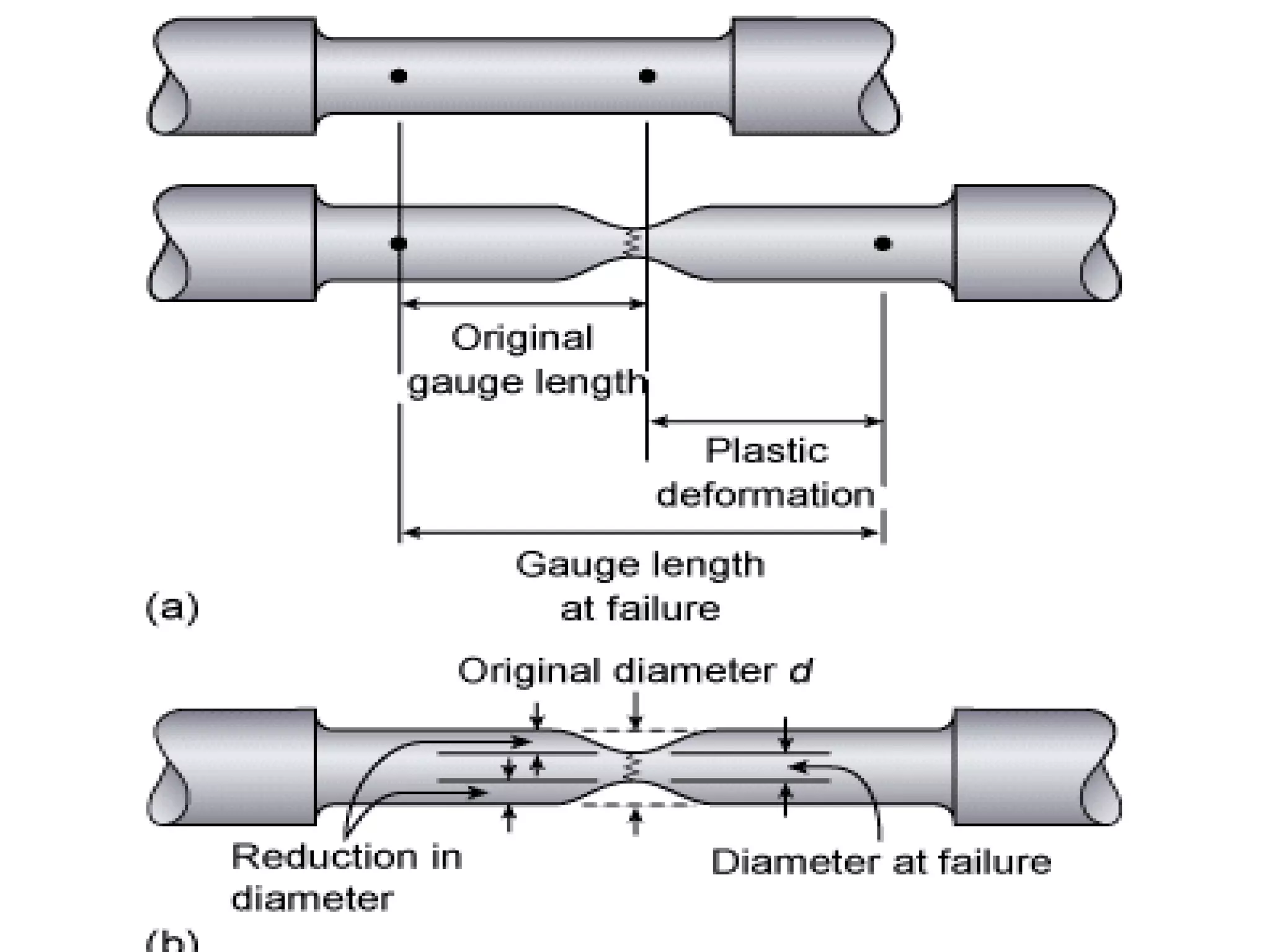

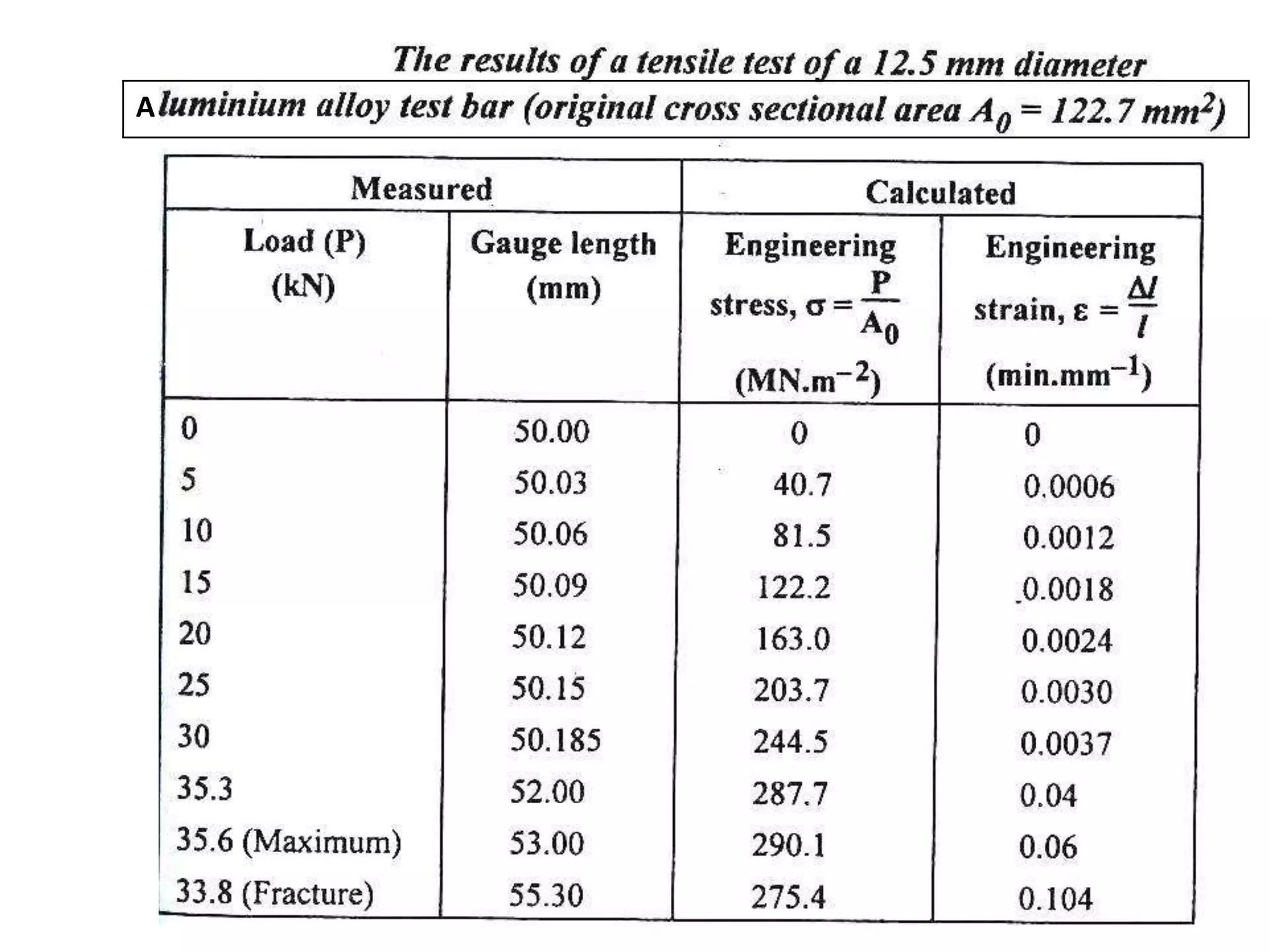

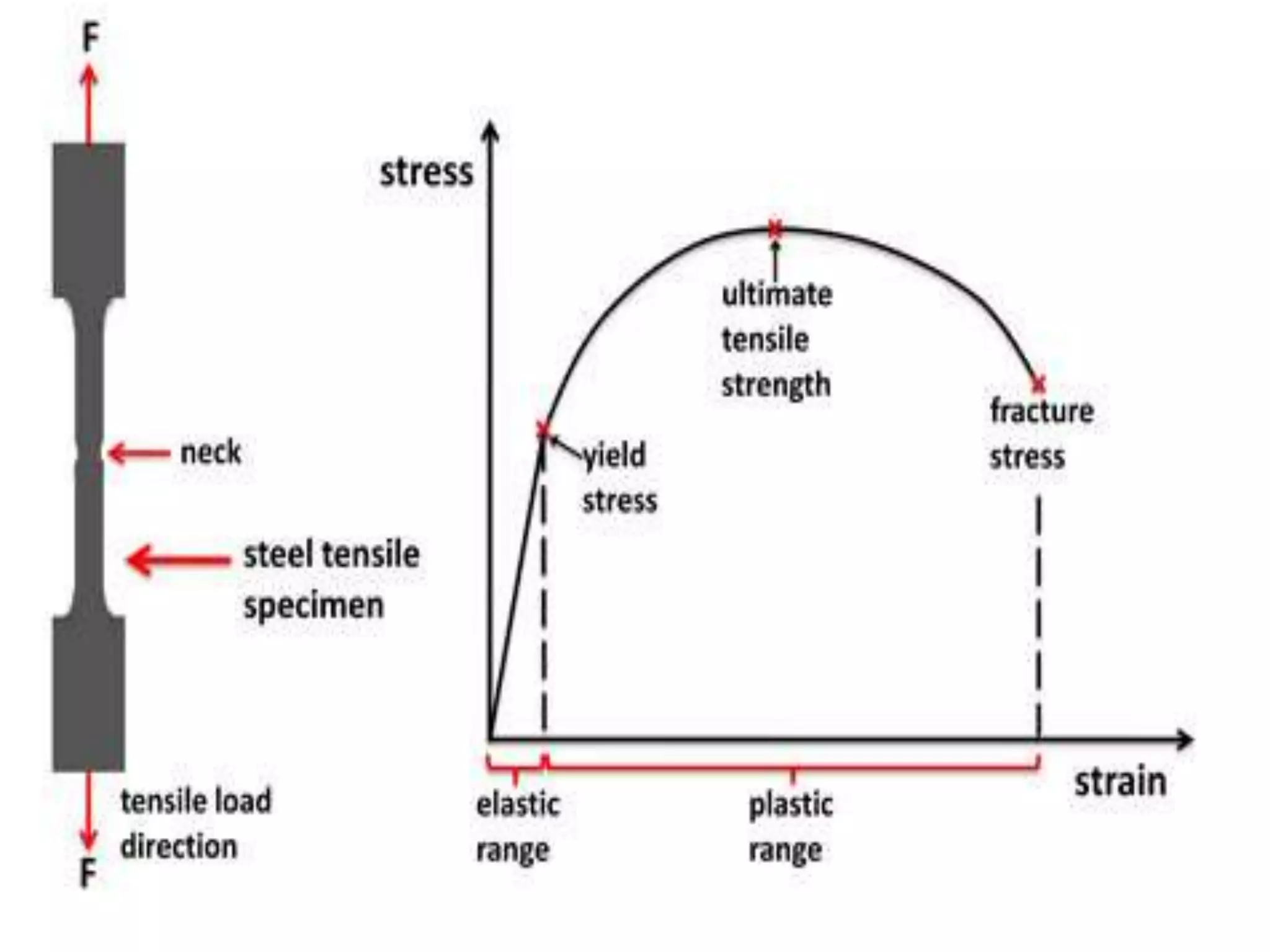

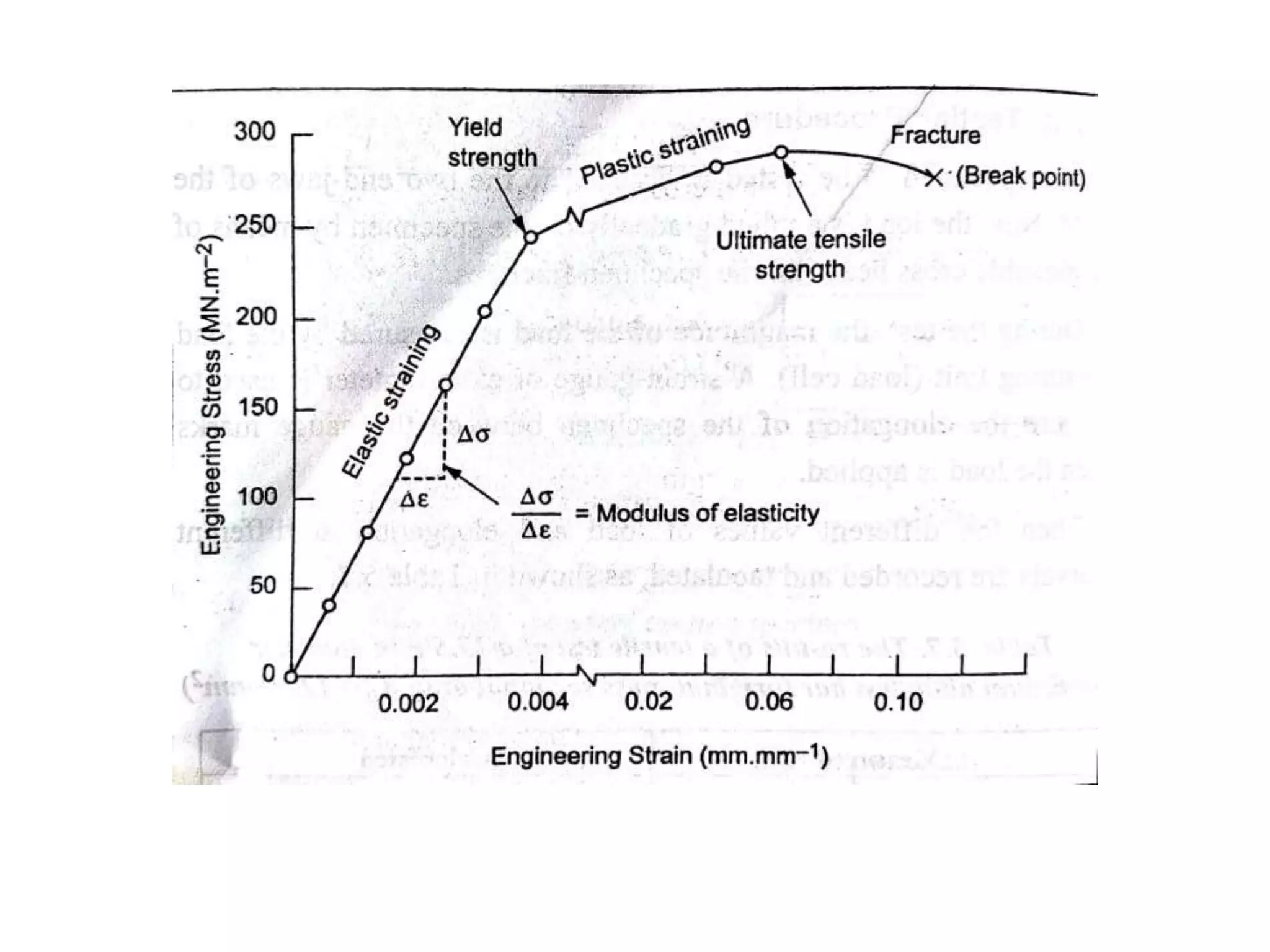

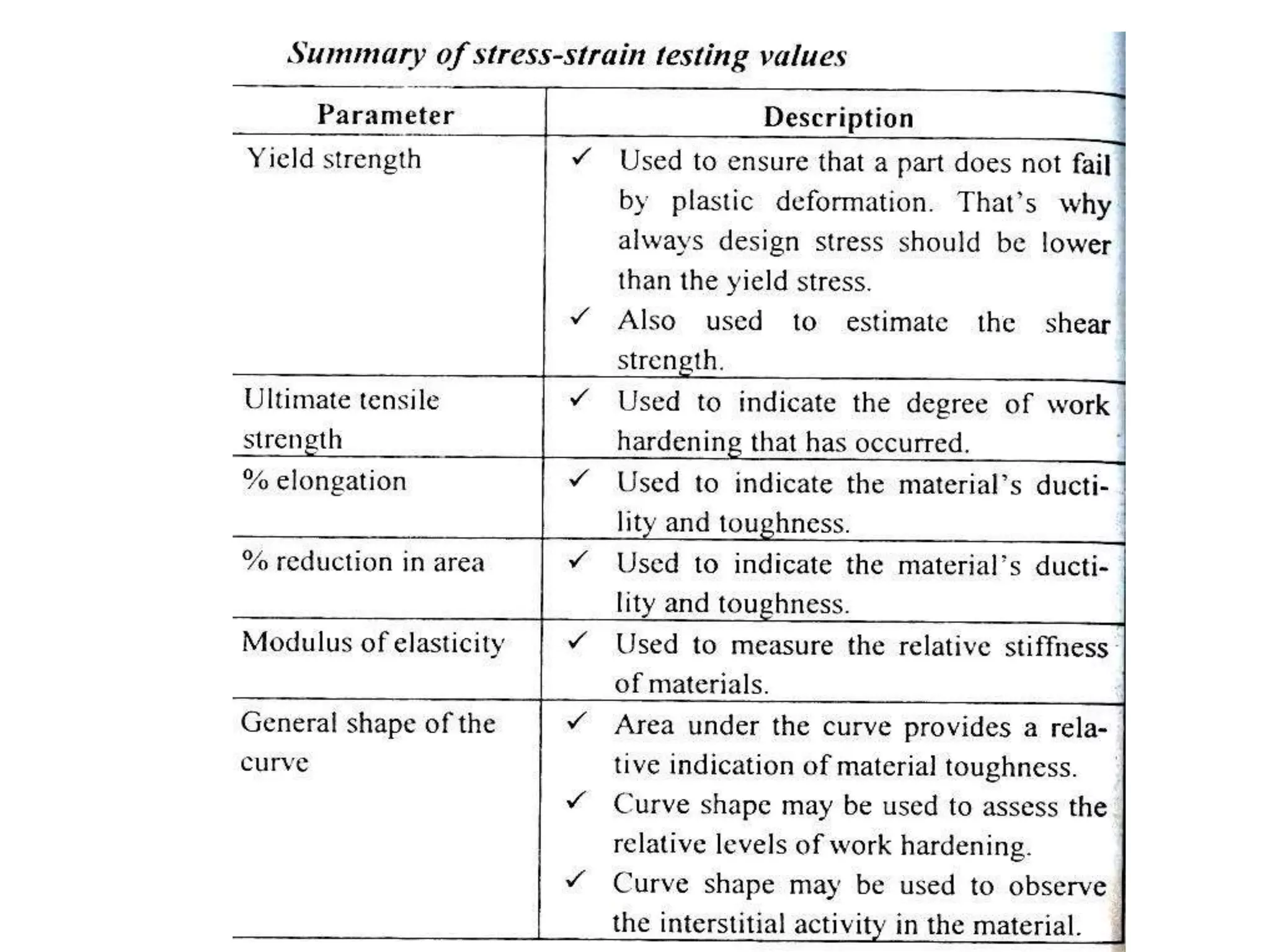

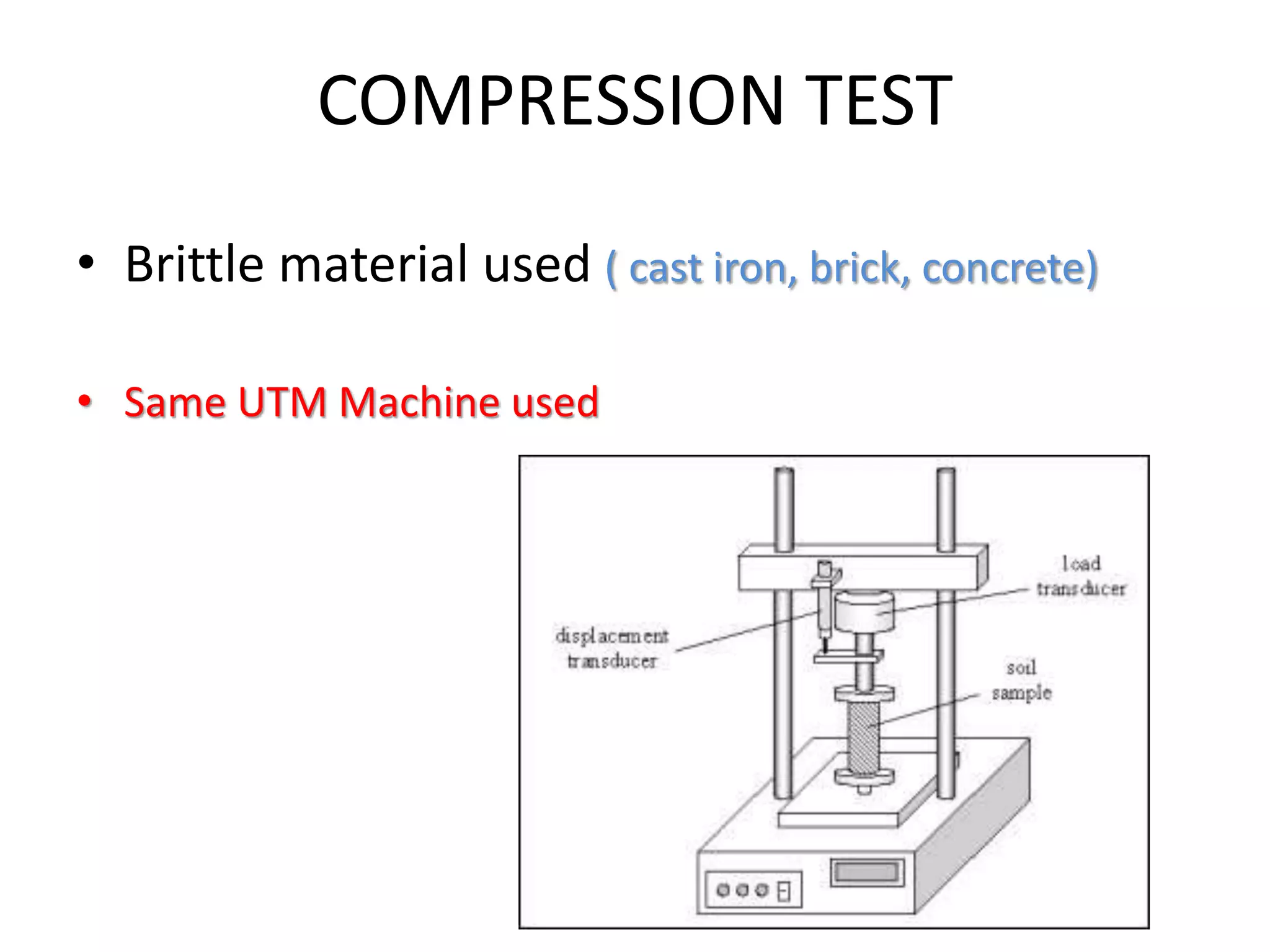

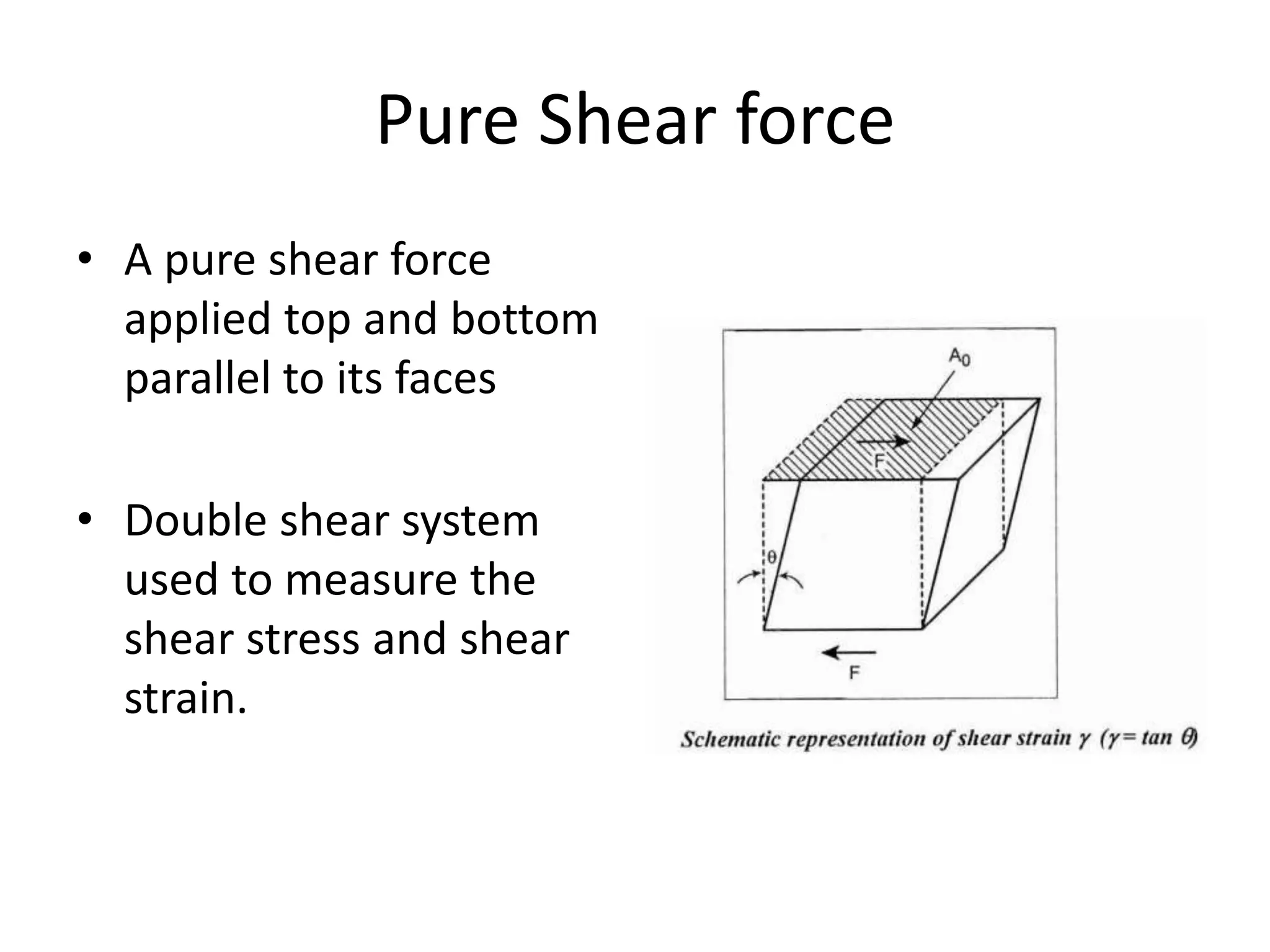

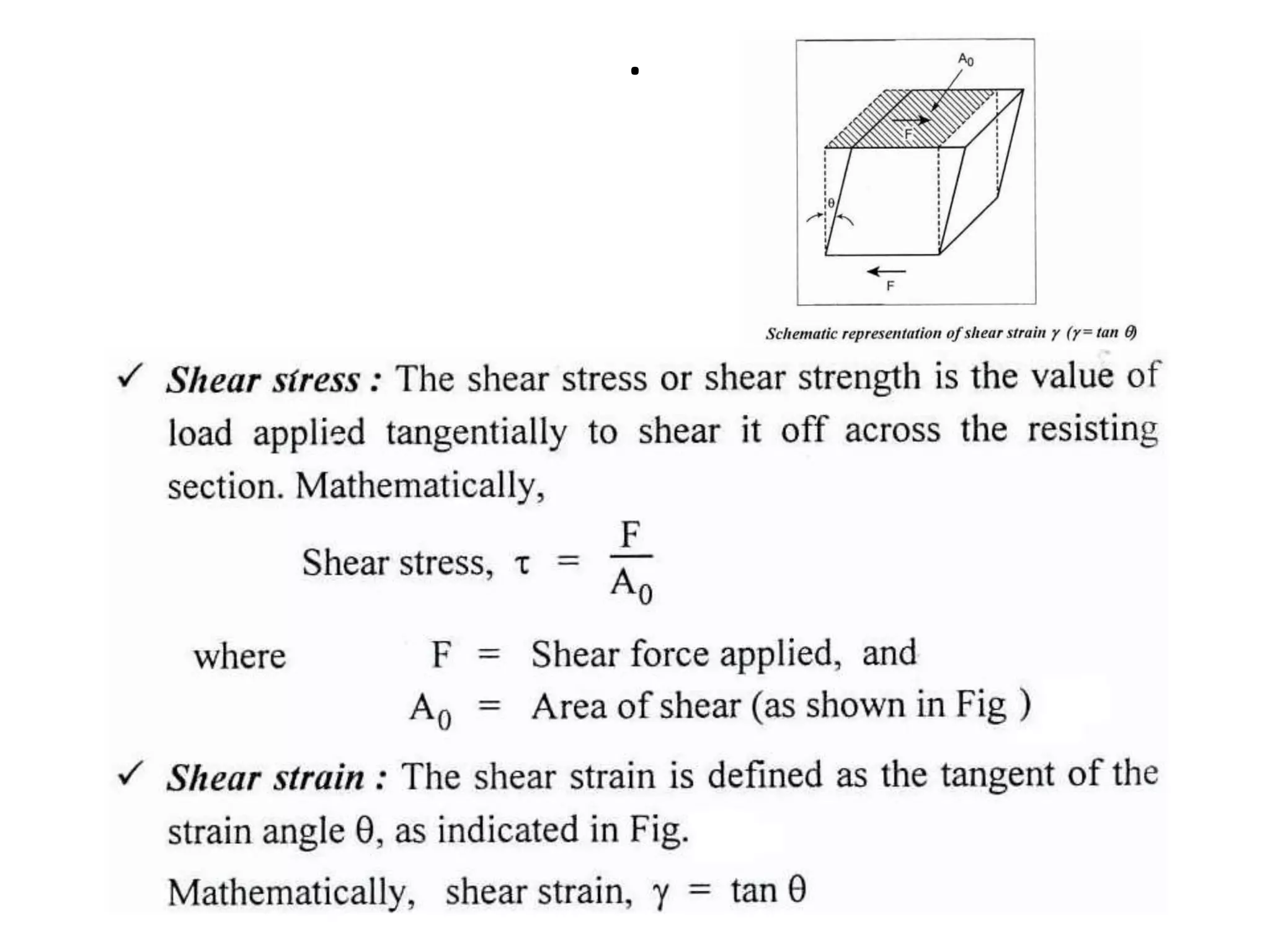

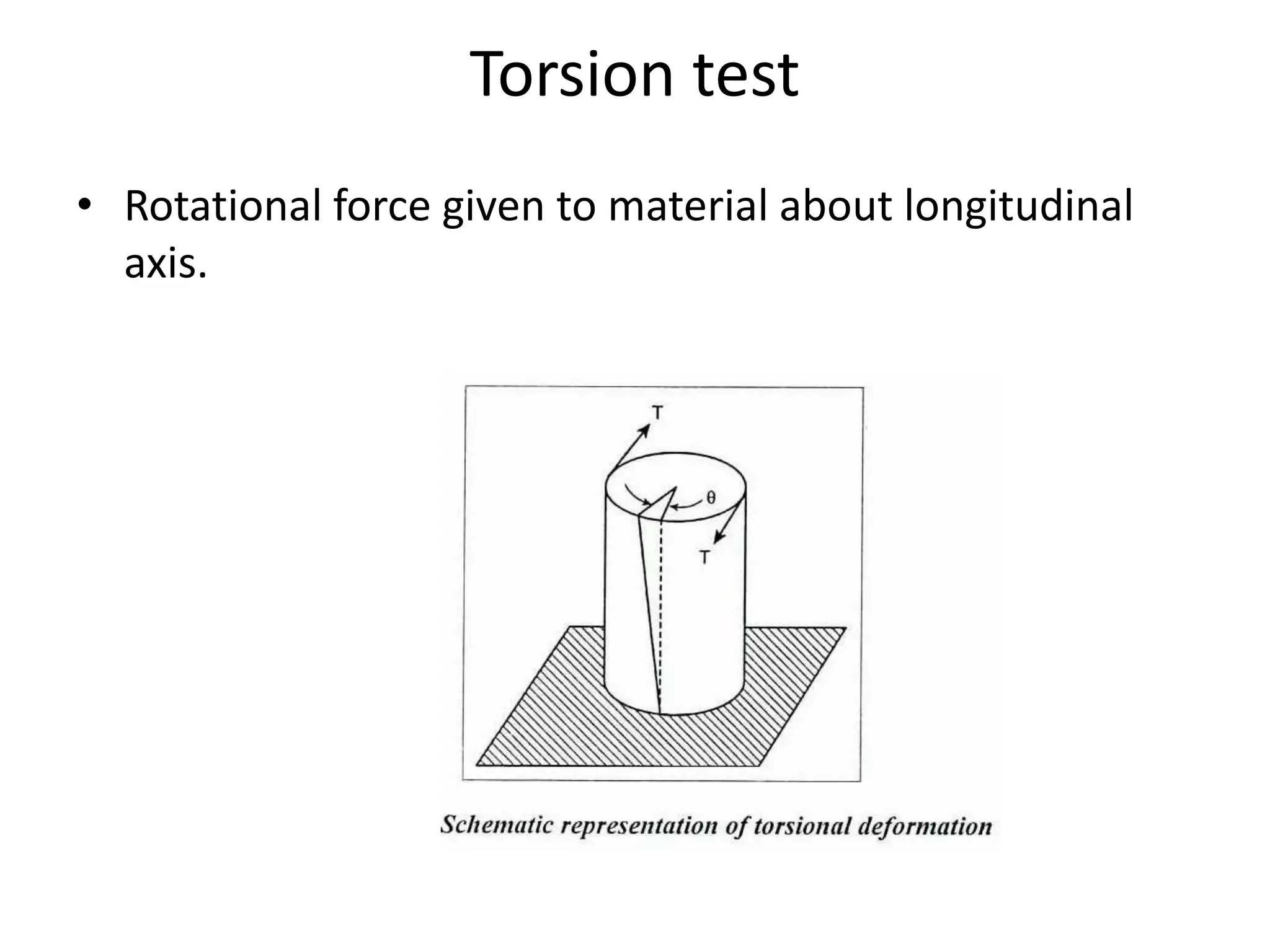

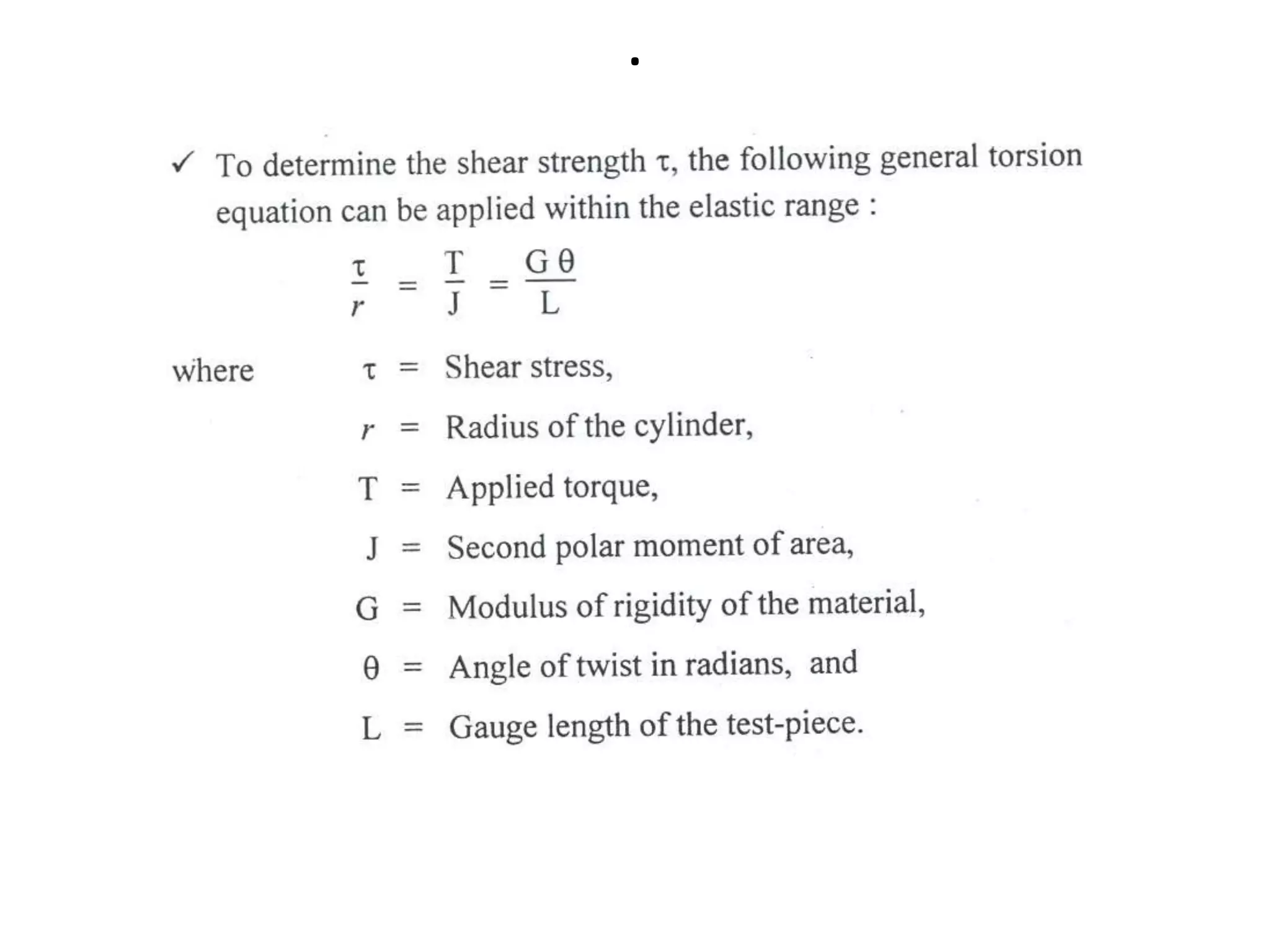

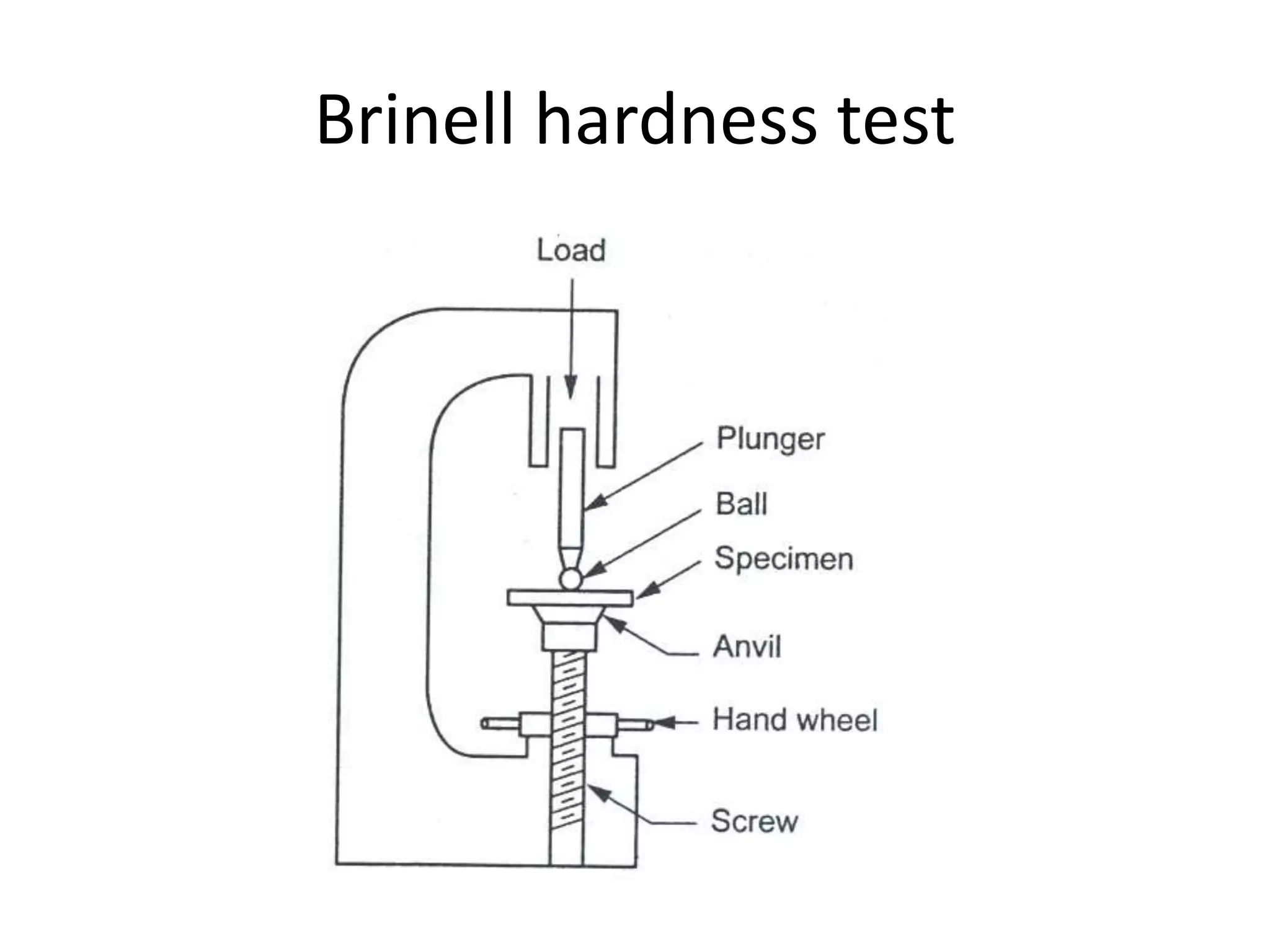

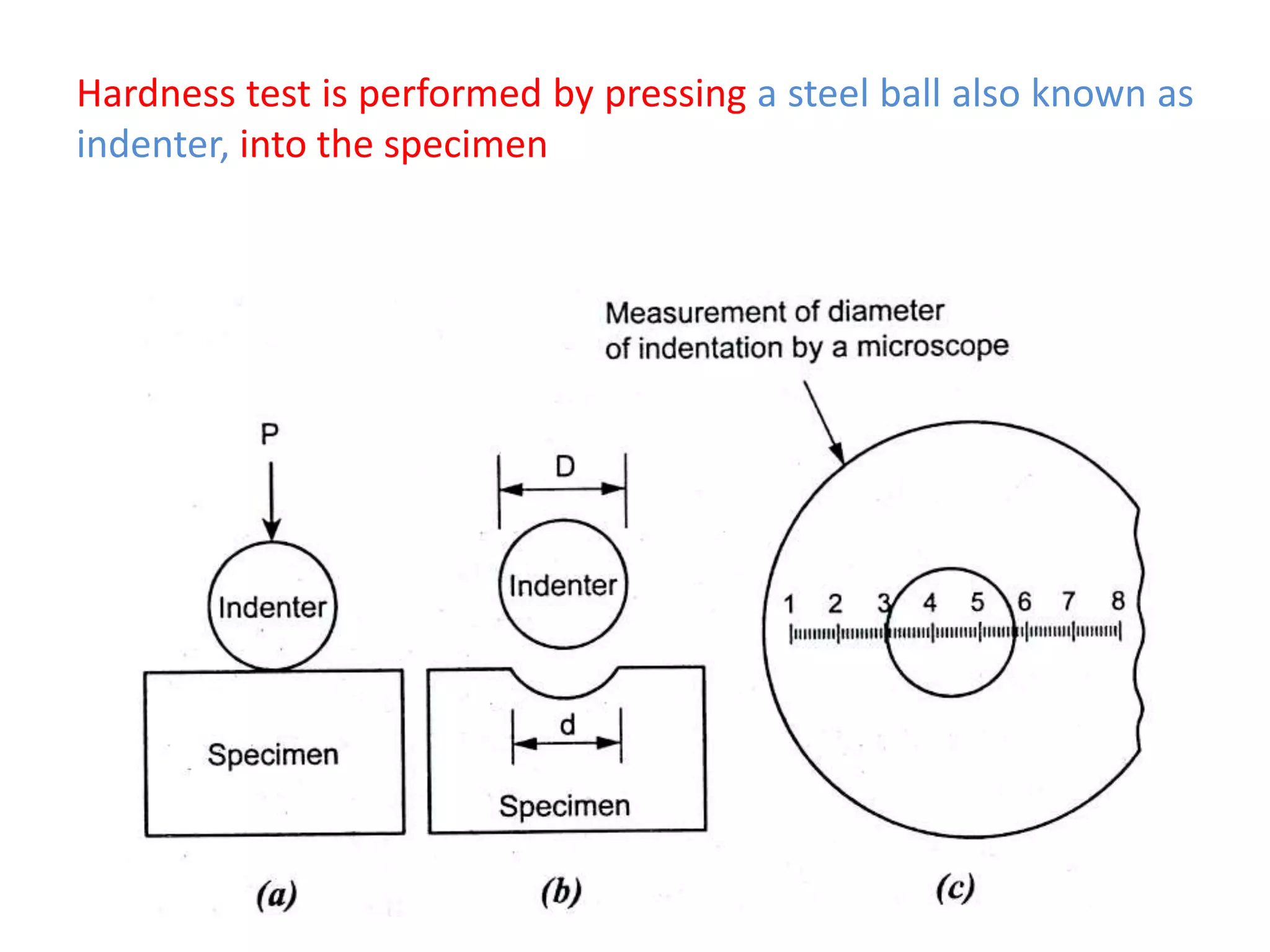

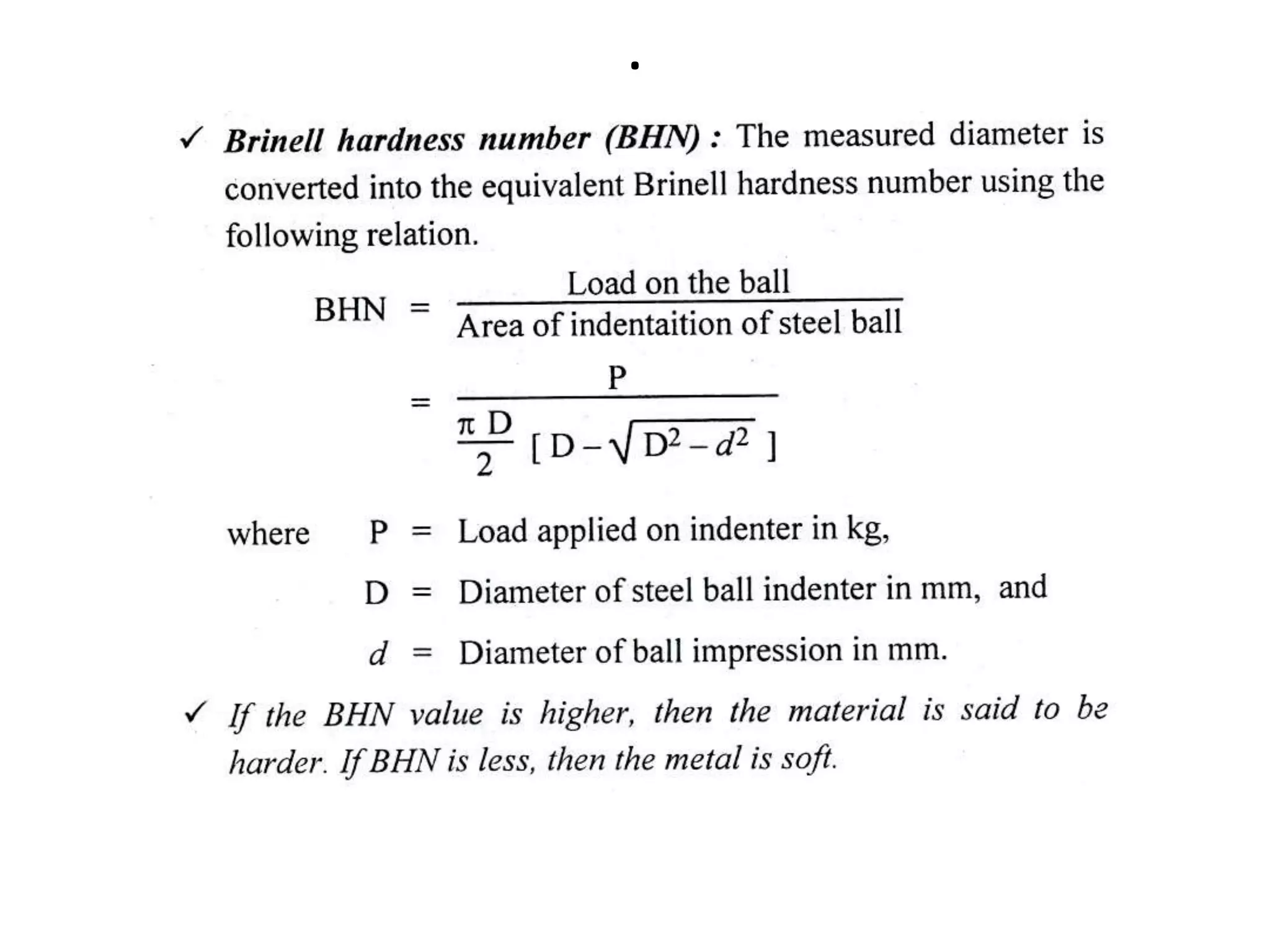

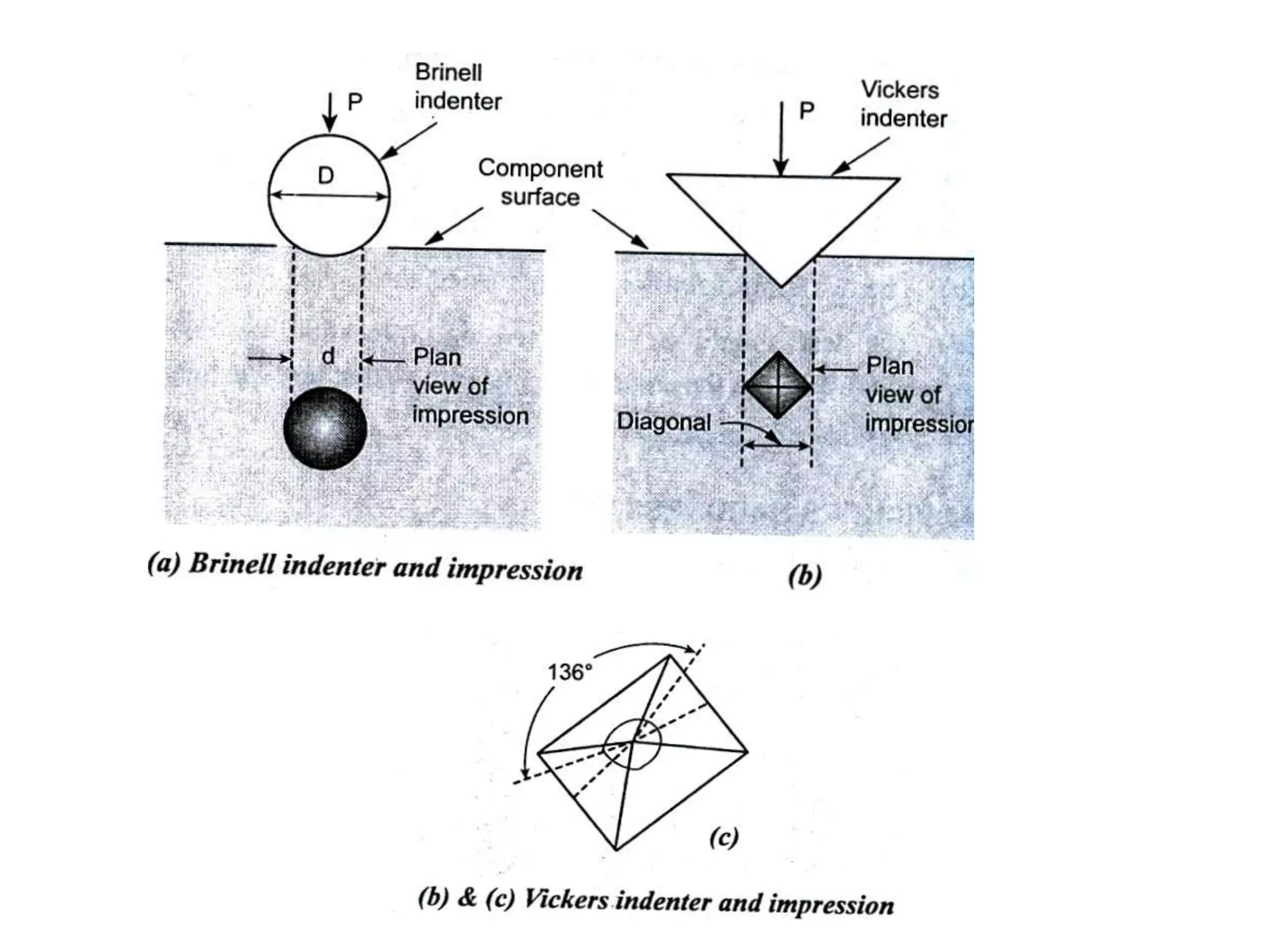

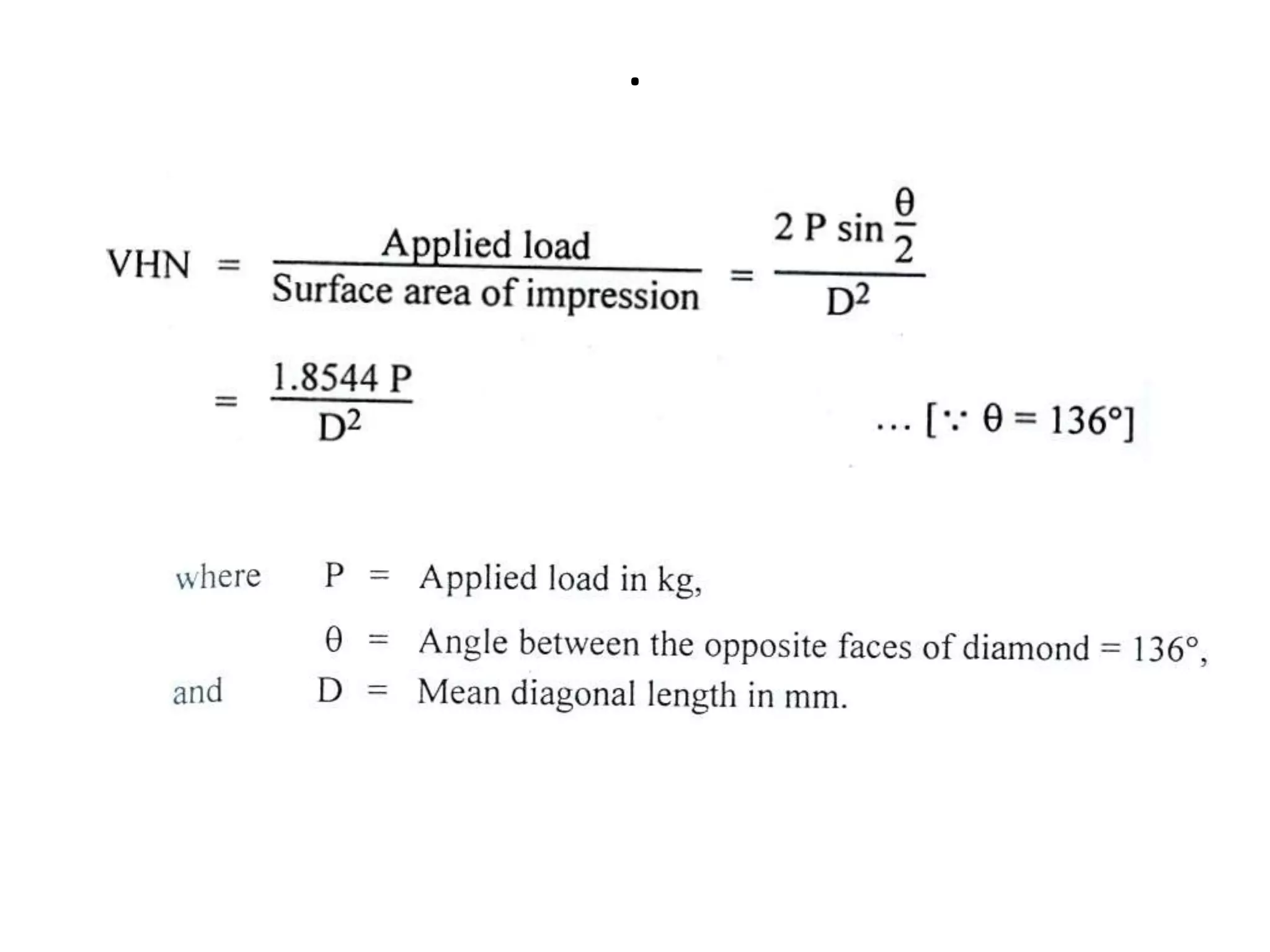

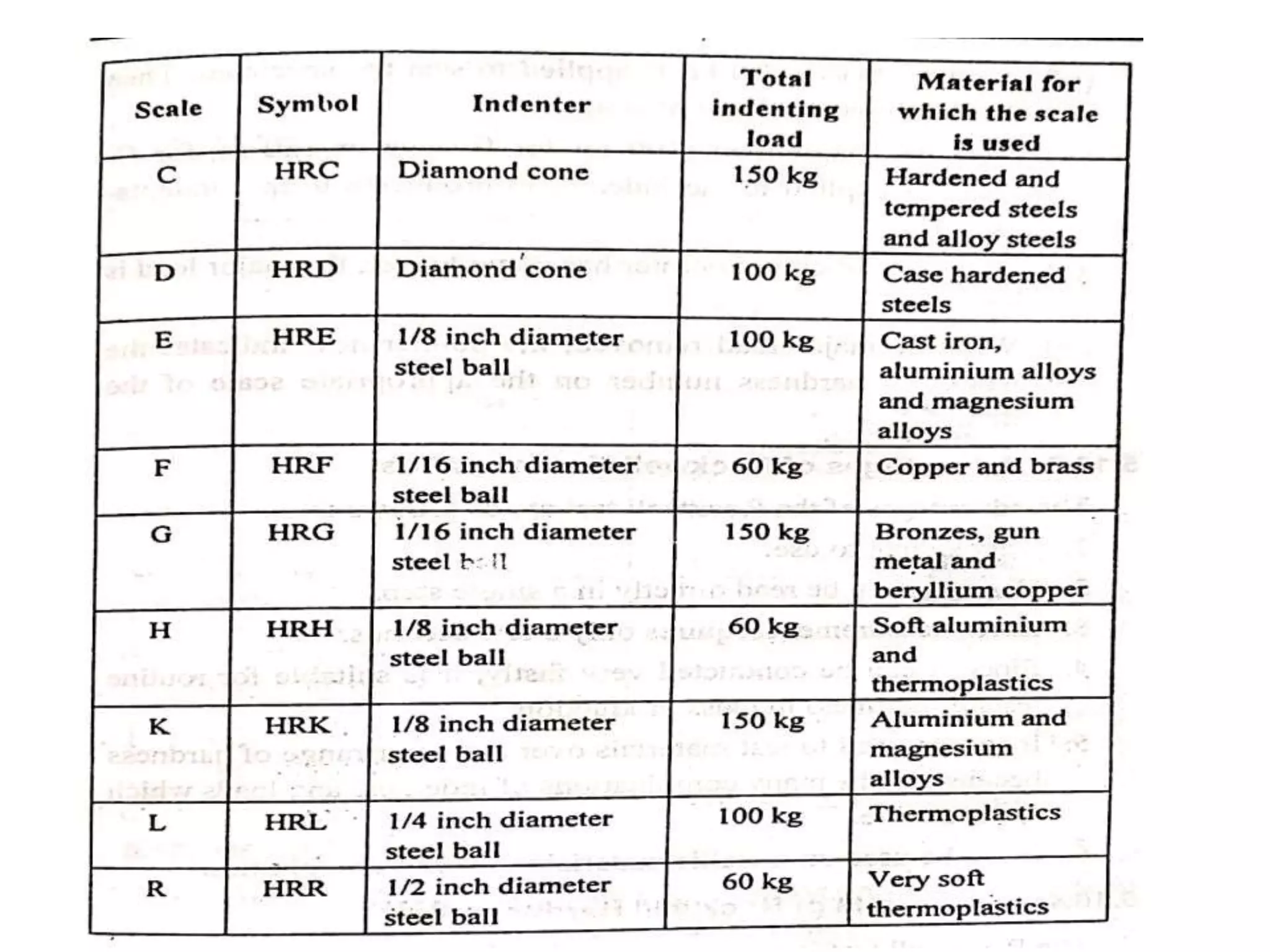

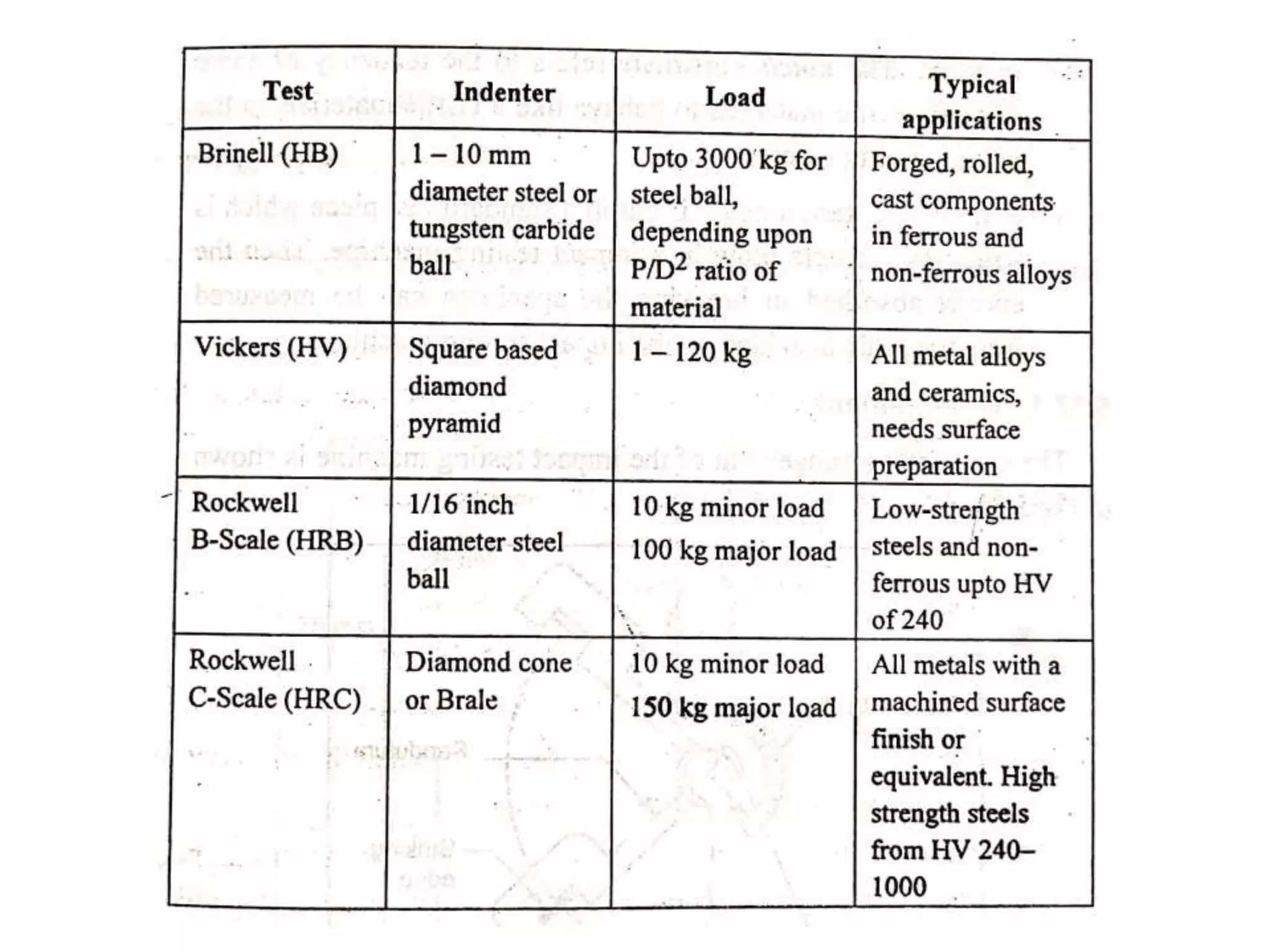

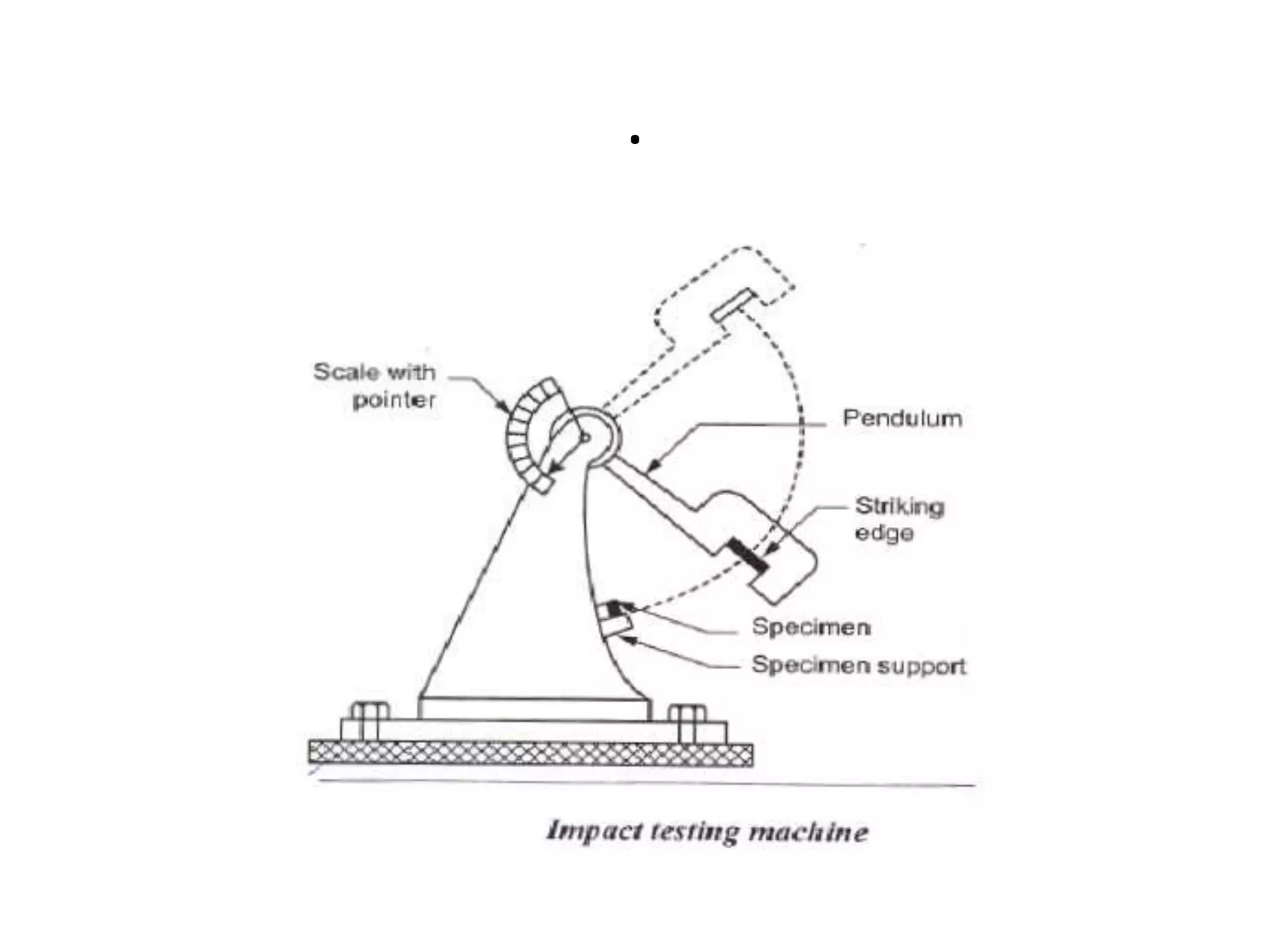

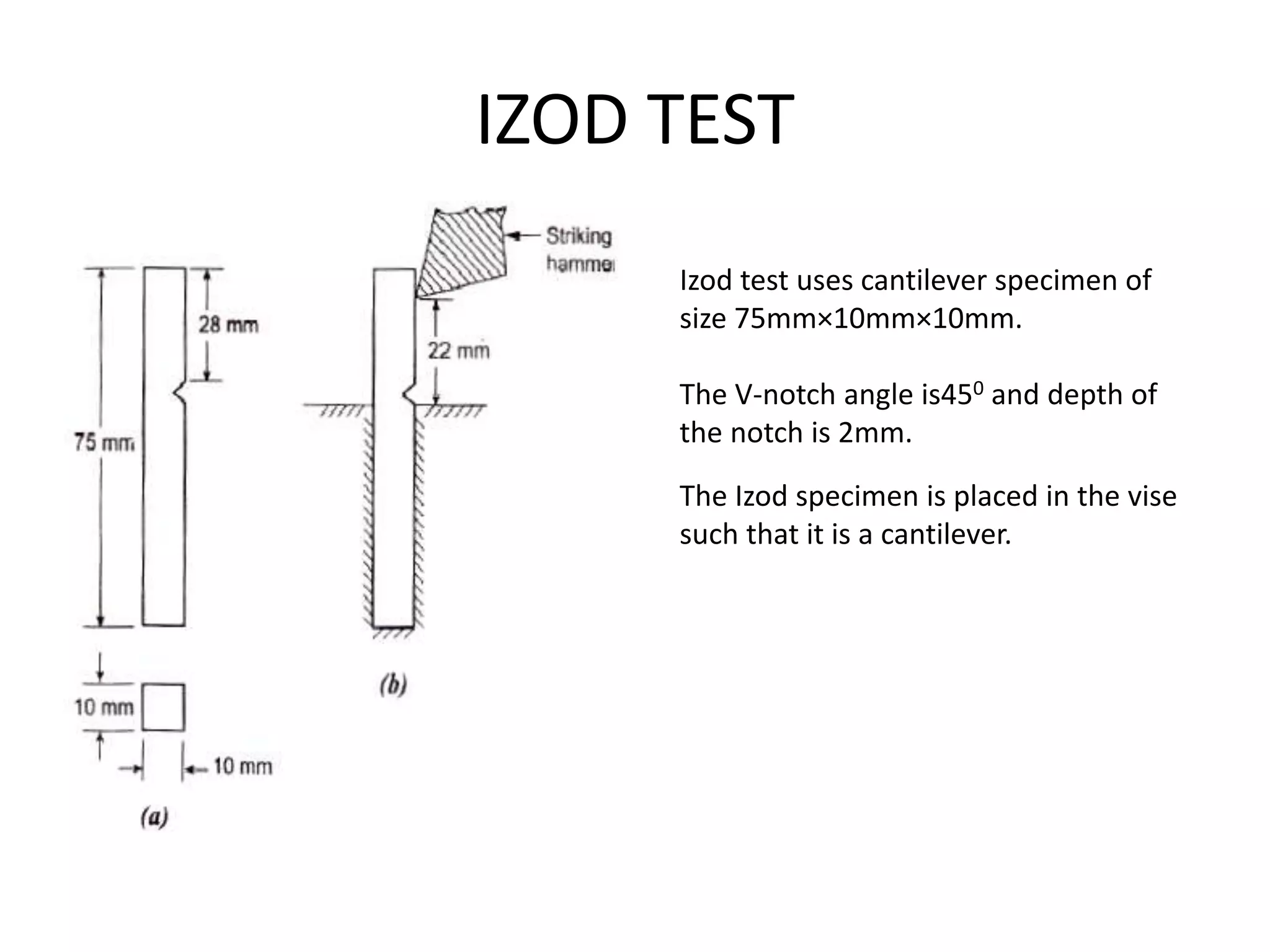

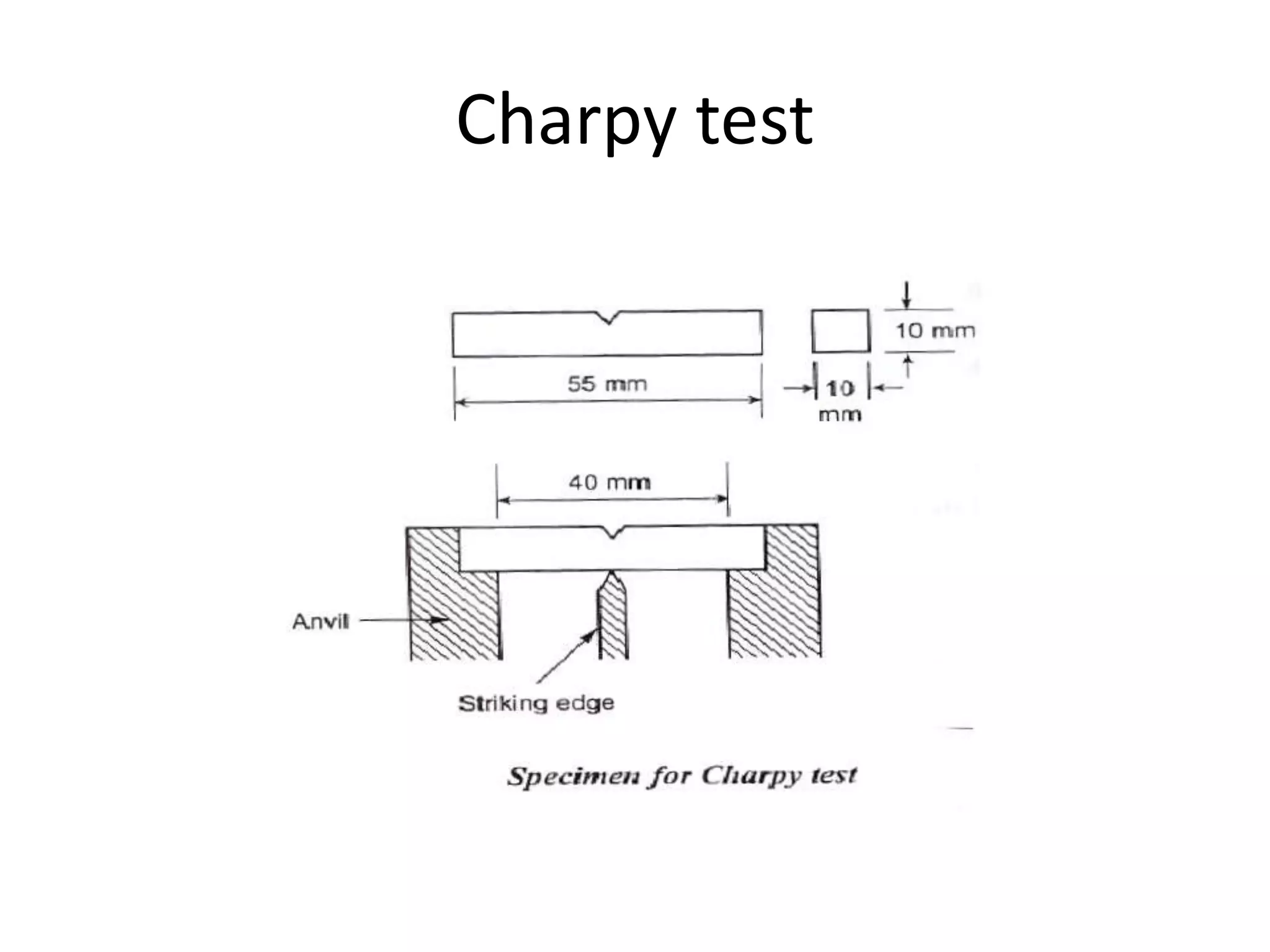

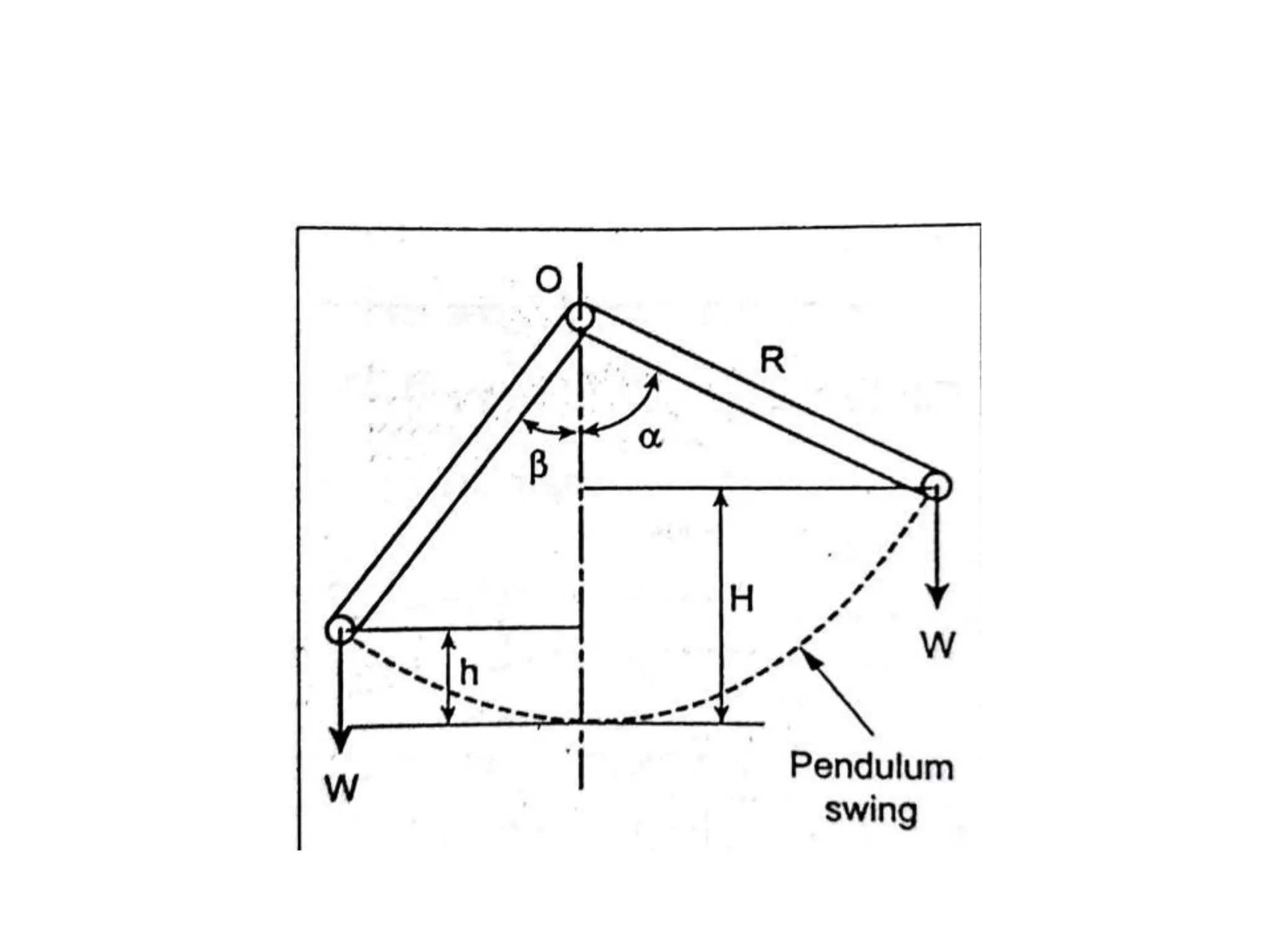

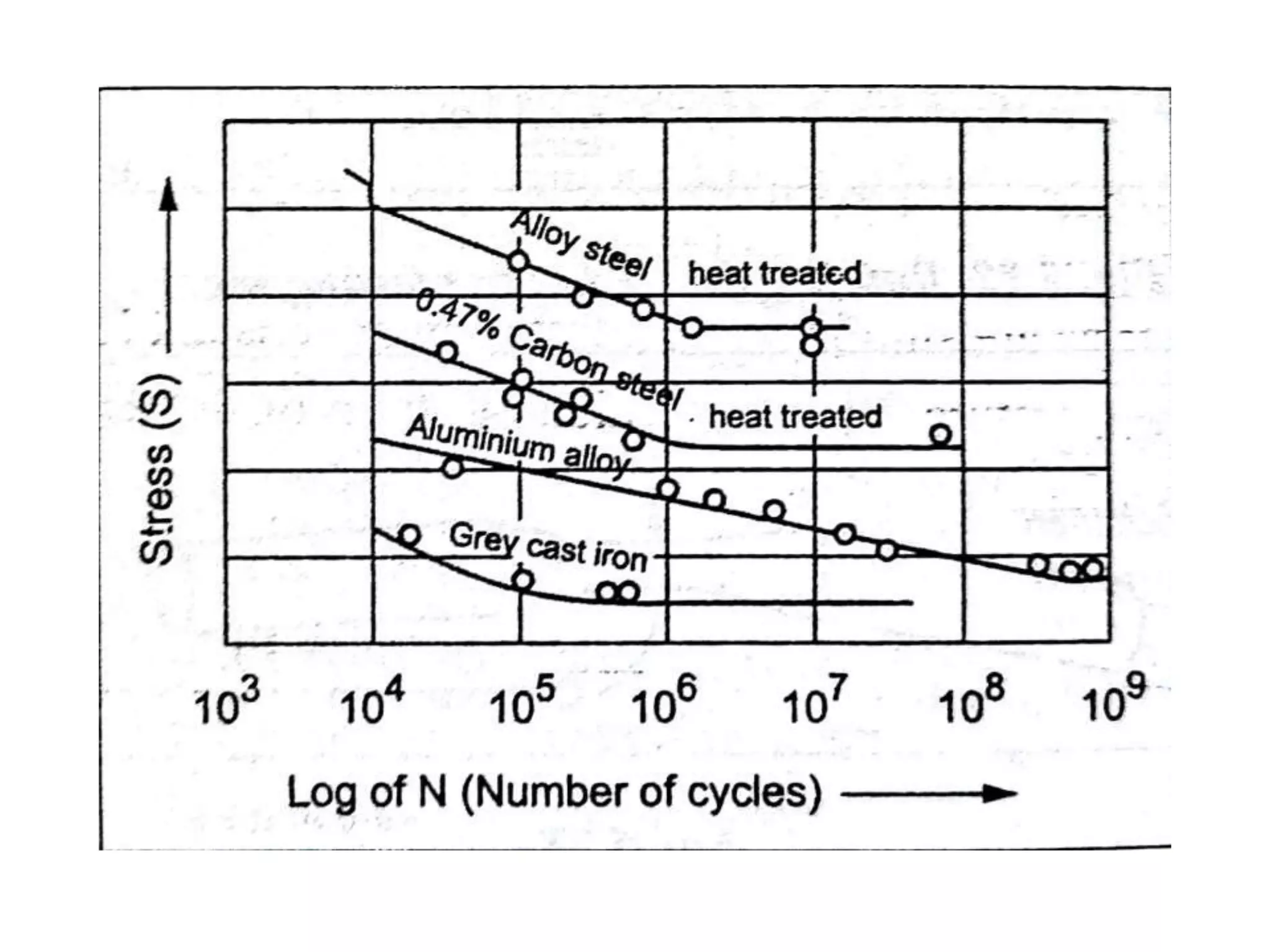

Mechanical tests of metals can be classified as either destructive or non-destructive. Destructive tests include tensile tests, used on ductile materials to measure strength and elongation; compression tests, used on brittle materials; and shear, torsion, impact, fatigue, and creep tests. Common non-destructive tests include hardness tests such as Brinell, Vickers, and Rockwell tests, which measure the hardness of a material. Mechanical tests are important to characterize the mechanical properties and behavior of engineering materials.