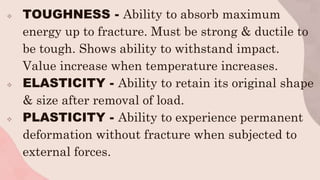

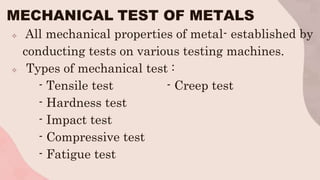

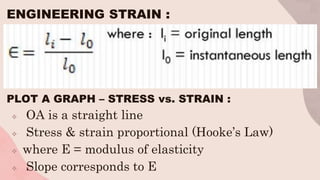

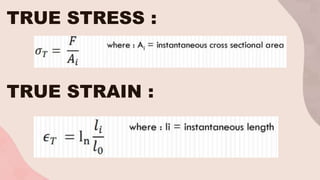

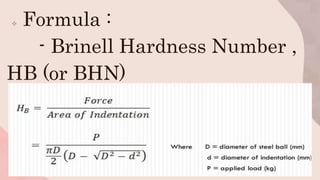

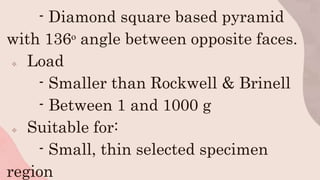

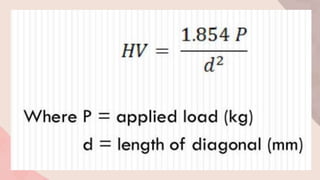

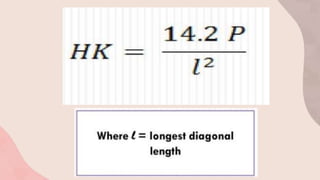

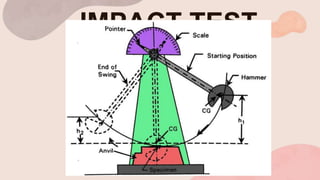

The document discusses mechanical properties of metals and testing methods. It covers various mechanical properties including strength, hardness, ductility, brittleness, toughness, elasticity, and plasticity. Common mechanical tests are also summarized such as tensile testing, hardness testing, impact testing, and fatigue testing. Standard specimens and procedures for tensile and hardness tests are described. True stress and strain are defined in relation to engineering stress and strain. The document also briefly mentions alloys and provides an example of Damascus steel.