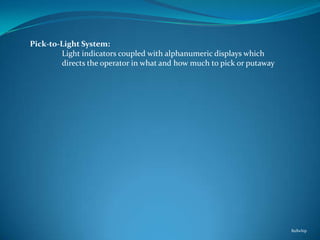

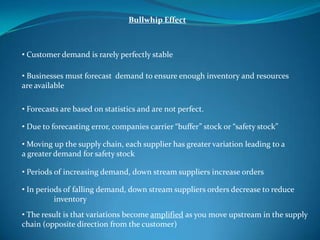

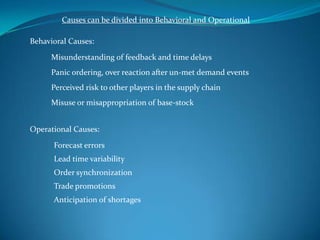

The document discusses technologies used in computerizing warehouse operations to streamline processes and minimize errors. It describes how identification technologies like barcodes, RFID, and smart cards work with communication systems using radio frequency, synthesized voice, displays, and pick-to-light systems to provide operators real-time information paperlessly. The bullwhip effect is explained as variations in customer demand amplifying as orders move up the supply chain due to forecasting errors and companies carrying buffer stock.