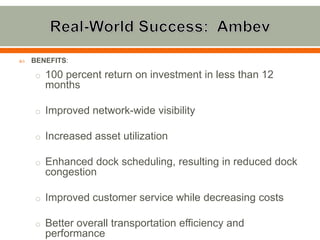

Demand for advanced transportation management systems is rising as businesses seek to reduce costs, address capacity constraints, and streamline operations. While optimization is key, not all optimization strategies are equal, and focusing on only one factor can do more harm than good. Companies need transportation management systems that use both heuristic and deterministic approaches concurrently to consider all elements like strategies, details, granularity, and constraints to find the best solution. Ambev saw significant benefits like a 100% ROI in under a year by replacing legacy systems with new transportation management technology.