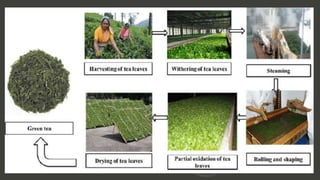

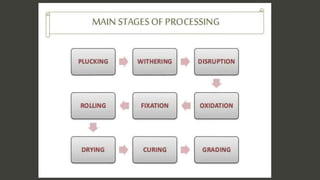

Tea processing transforms leaves from the Camellia sinensis plant into dried leaves for brewing, involving various methods of oxidation and other treatments. The process includes stages like plucking, withering, oxidation, drying, and curing, which influence the distinct types of tea, such as green, yellow, white, oolong, and black. The history of tea processing is closely linked to its cultural significance in Chinese society and has evolved with different techniques over time.

![Rolling / shaping

● The damp tea leaves are

then rolled to be formed

into wrinkled strips, by

hand[9] or using a rolling

machine which causes the

tea to wrap around itself.

● The strips of tea can then

be formed into other

shapes, such as being rolled

into spirals, kneaded and

rolled into pellets, or tied

into balls, cones and other

elaborate shapes.](https://image.slidesharecdn.com/processingofteabytanyathakuea43126180241-220922100710-5b73f90b/85/Processing-Of-Tea-12-320.jpg)