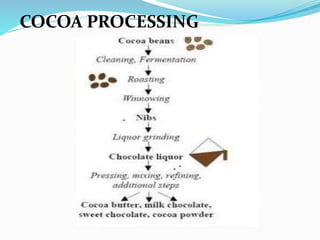

The document discusses the cocoa plant and cocoa processing. It describes the three main types of cocoa pods - Forastero, Criollo, and Trinitario. It then outlines the various steps involved in processing cocoa beans into products like cocoa butter, cocoa powder, and chocolate, including fermentation, drying, roasting, grinding, and pressing. The key steps are fermenting the beans to develop flavor, drying them, roasting to further develop flavor, and grinding to produce cocoa mass, butter, and powder.