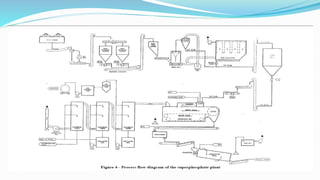

The document summarizes the production process of single super phosphate (SSP) fertilizer. SSP is produced using phosphate rock, which is ground and blended. It is then reacted with sulfuric acid in a horizontal mixer. The resulting slurry drops into a den to partially cure before granulation. The granulation process forms granules which are screened and stored to fully cure before use. Environmental controls monitor dust and gaseous emissions during production. SSP provides phosphorus and sulfur to crops while protecting soils.