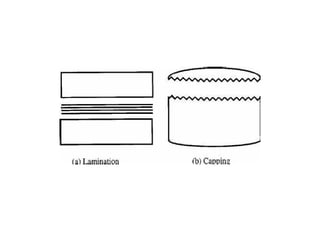

Tablet compression is the process of turning powdered pharmaceutical ingredients into solid dosage forms like tablets through pressure, aiming for precise dosage and stability. The process involves stages such as granulation, blending, feeding, compression, and ejection, utilizing methods like wet and dry granulation. Key challenges include maintaining tablet integrity, managing weight variation, and optimizing equipment settings for consistent quality.