This document describes a carbon nanotube sensor system for monitoring transformer insulation oil. It consists of 3 sentences:

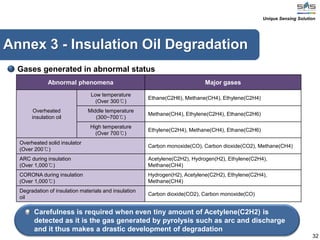

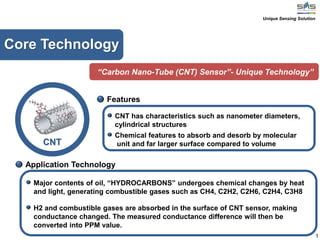

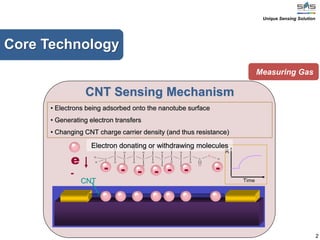

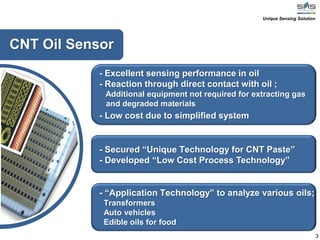

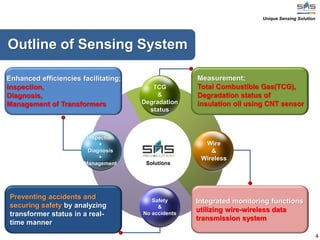

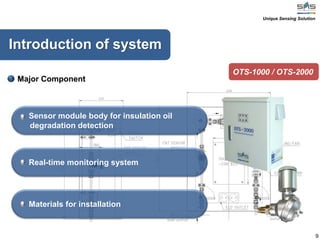

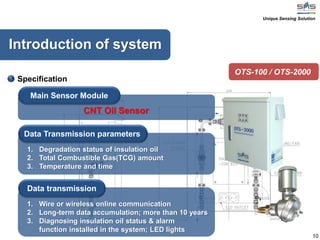

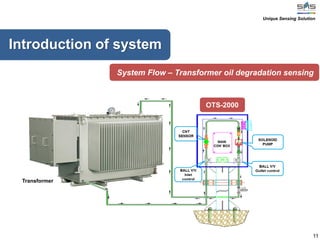

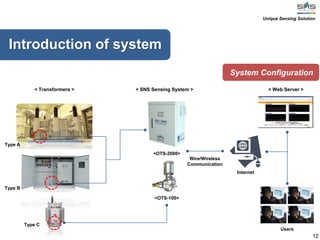

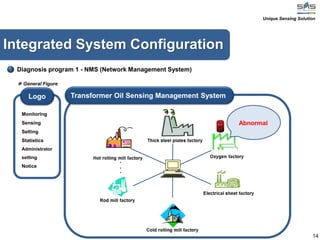

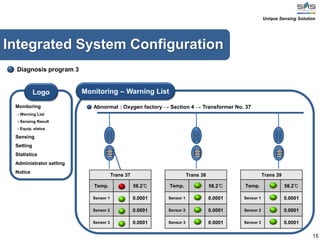

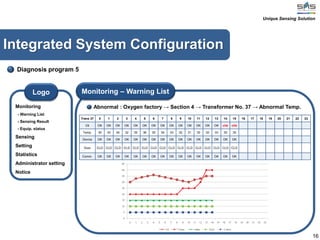

The system uses a carbon nanotube sensor to detect combustible gases produced from degradation of insulation oil. It can continuously monitor multiple transformers in real-time through a wireless network. Test results showed the carbon nanotube sensor accurately measured changes in combustible gases compared to gas chromatography analysis.

![28

Annex 2

Analysis data - Transformer insulation oil

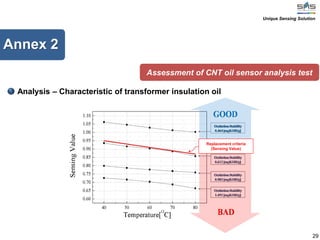

Assessment of CNT oil sensor analysis test

Sensing Rate of CNT Sensor

OxidationStability

[mgKOH/g]

DielectricStrength

[KV]

※ MICHANG OIL IND.CO.,LTD Analysis Data 2008.01

Unique Sensing Solution](https://image.slidesharecdn.com/t-1transformerinsulationoilsensingsystem-140805100840-phpapp02/85/T-1-transformer-insulation-oil-sensing-system-29-320.jpg)