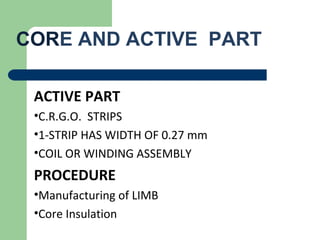

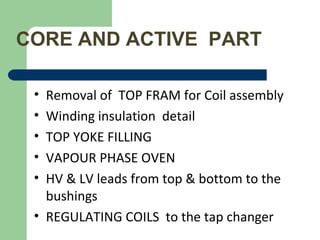

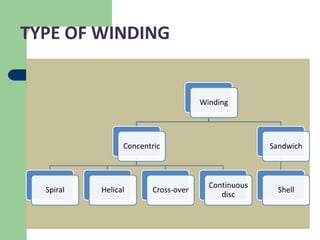

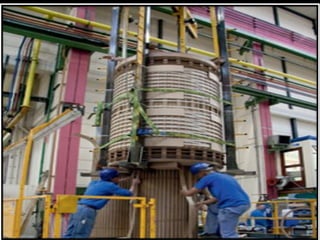

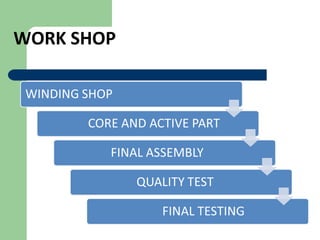

This document summarizes the key components and manufacturing process of a power transformer. It discusses the core materials used, including cold rolled grain oriented silicon steel which has excellent magnetic properties and reduces hysteresis losses. It describes the winding assembly process and different types of windings like spiral, helical, and sandwich windings. It also covers the different insulation materials and methods used, as well as testing procedures to ensure quality.