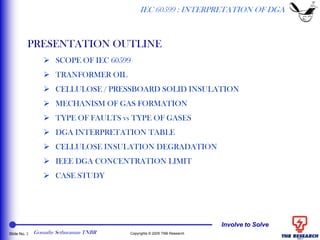

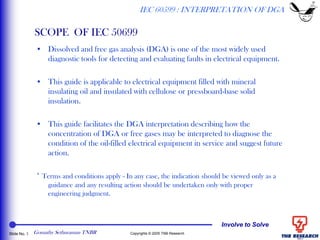

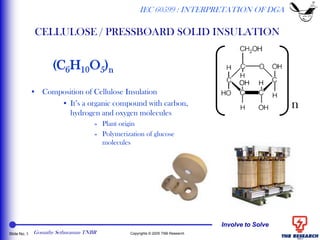

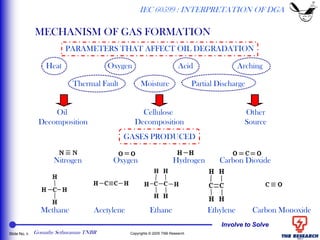

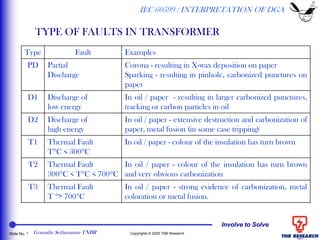

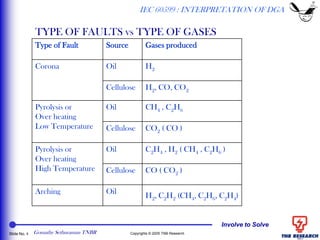

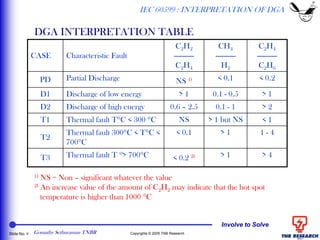

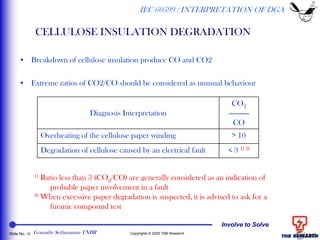

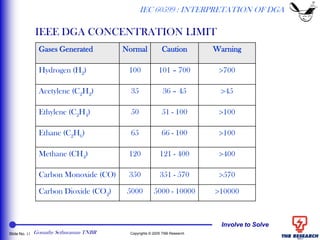

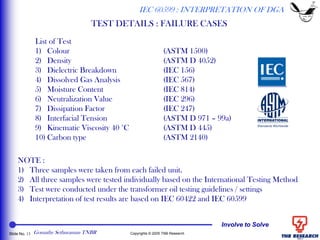

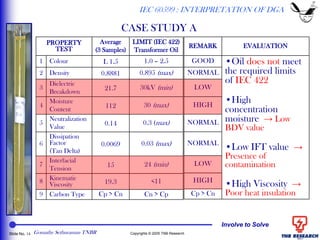

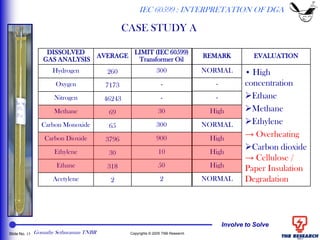

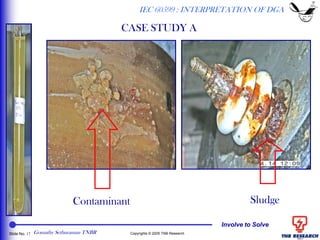

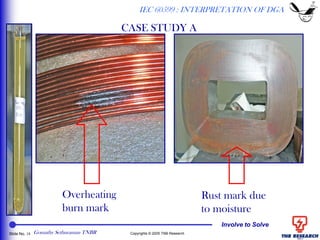

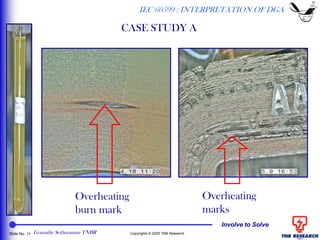

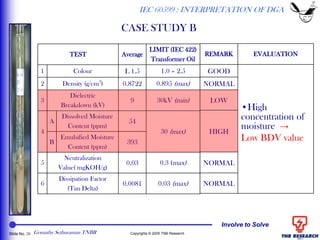

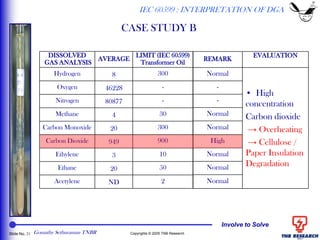

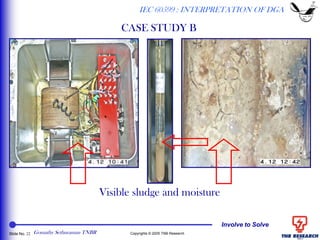

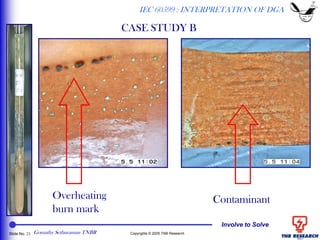

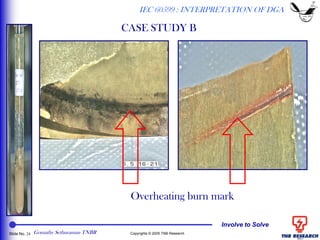

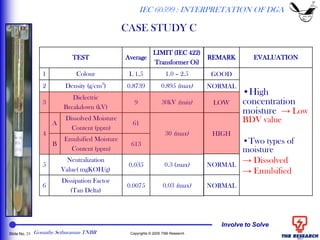

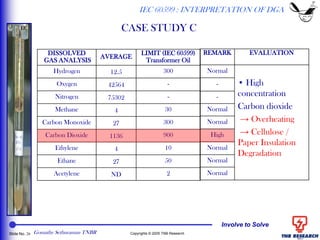

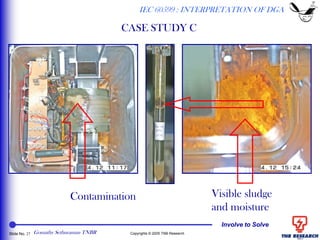

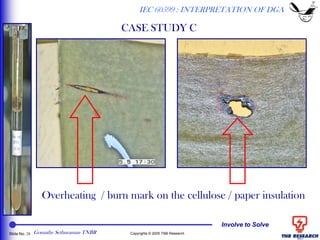

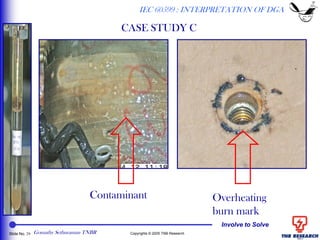

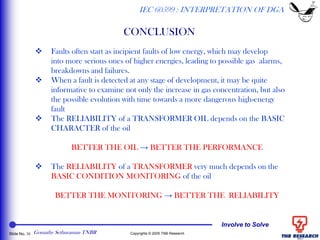

The document is a presentation on interpreting dissolved gas analysis (DGA) of transformer oil based on IEC 60599 guidelines. It discusses the scope of IEC 60599, components of transformer oil and cellulose insulation, mechanisms of gas formation, relationship between fault types and produced gases, DGA interpretation tables, indicators of cellulose degradation, IEEE gas concentration limits, and includes case studies of transformer oil analysis. The presentation provides information on using DGA to diagnose equipment condition and faults in electrical transformers.