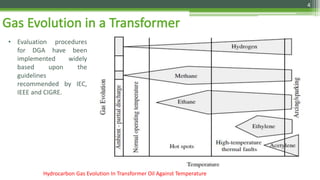

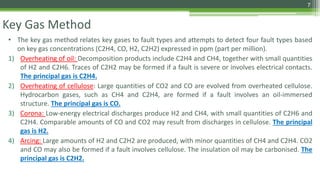

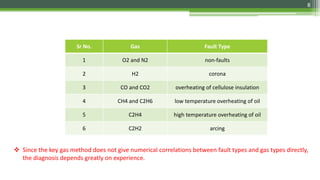

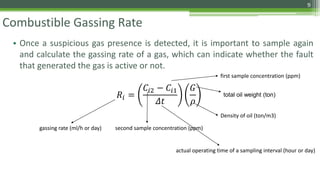

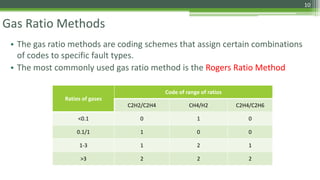

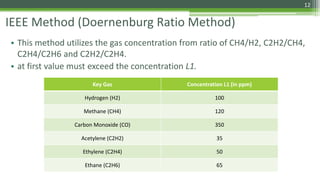

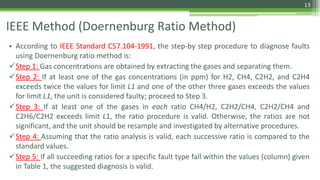

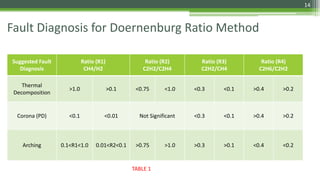

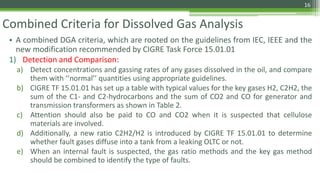

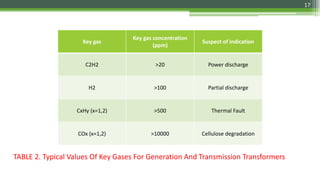

The document discusses dissolved gas analysis (DGA) in transformers, detailing how internal faults produce combustible gases that indicate specific fault types like overheating or arcing. It outlines various DGA methods, including the key gas method, gas ratio methods, and the IEEE Doernenburg ratio method for diagnosing faults based on gas concentrations. Additionally, it emphasizes the importance of monitoring gas concentrations and applying combined criteria for assessing transformer health and taking appropriate actions.