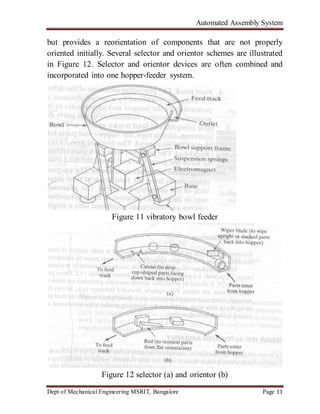

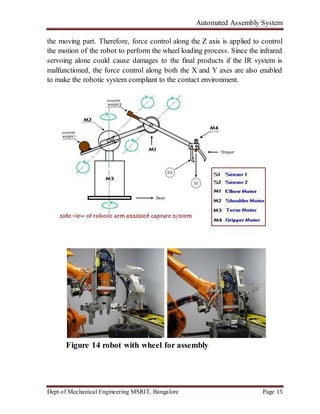

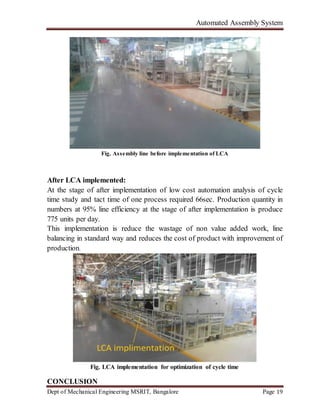

The document discusses the automated assembly systems used in manufacturing, emphasizing the principles of design that facilitate automation, such as modular design, reducing the number of fasteners, and ensuring high quality components. It outlines various types of assembly systems and the importance of optimization for cycle time in automotive manufacturing, highlighting a case study that successfully increased production efficiency. Additionally, advancements such as robotic systems for wheel loading and the application of visual servoing and force control are explored as vital to improving assembly processes.

![Automated Assembly System

Dept of Mechanical Engineering MSRIT, Bangalore Page 21

1. Artun Torenli [2009], “Assembly line design and optimization”, Master of

science thesis in the International Masters programme automotive engineering,

Chalmers university Of Technology Goteborg, Sweden.

2. Dr. Jay Baron, Brett C. Smith [2006], “Low-Volume Vehicle

Production by Manufacturing, Engineering and Technology”,Center for

Automotive Research, USA.

3. G Reinhart, J Werner [2009], “Flexible Automation for the

Assembly in Motion”, Institute for Machine Tools.](https://image.slidesharecdn.com/automatedassemblysystems-180529084831/85/Automated-assembly-systems-21-320.jpg)