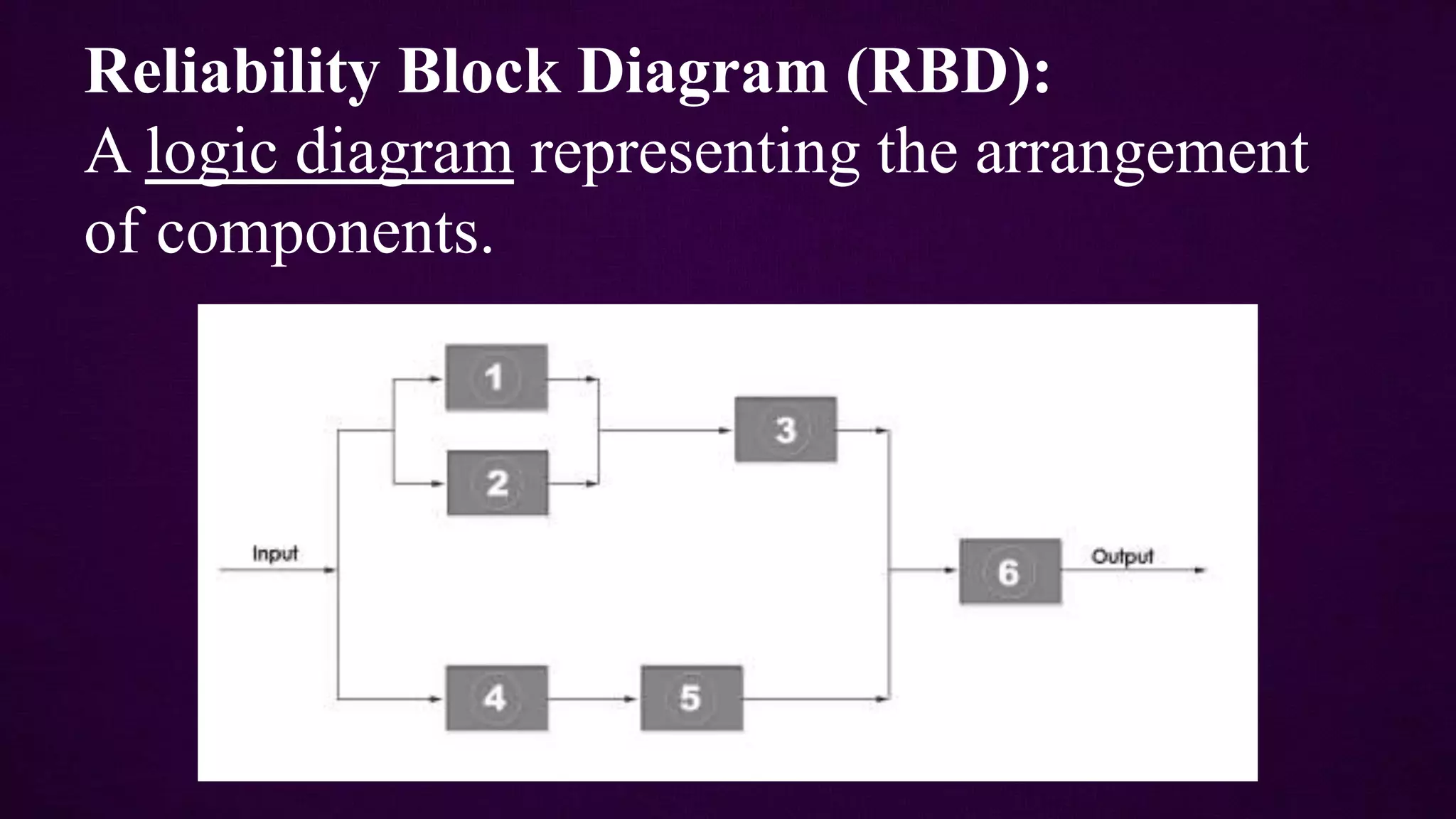

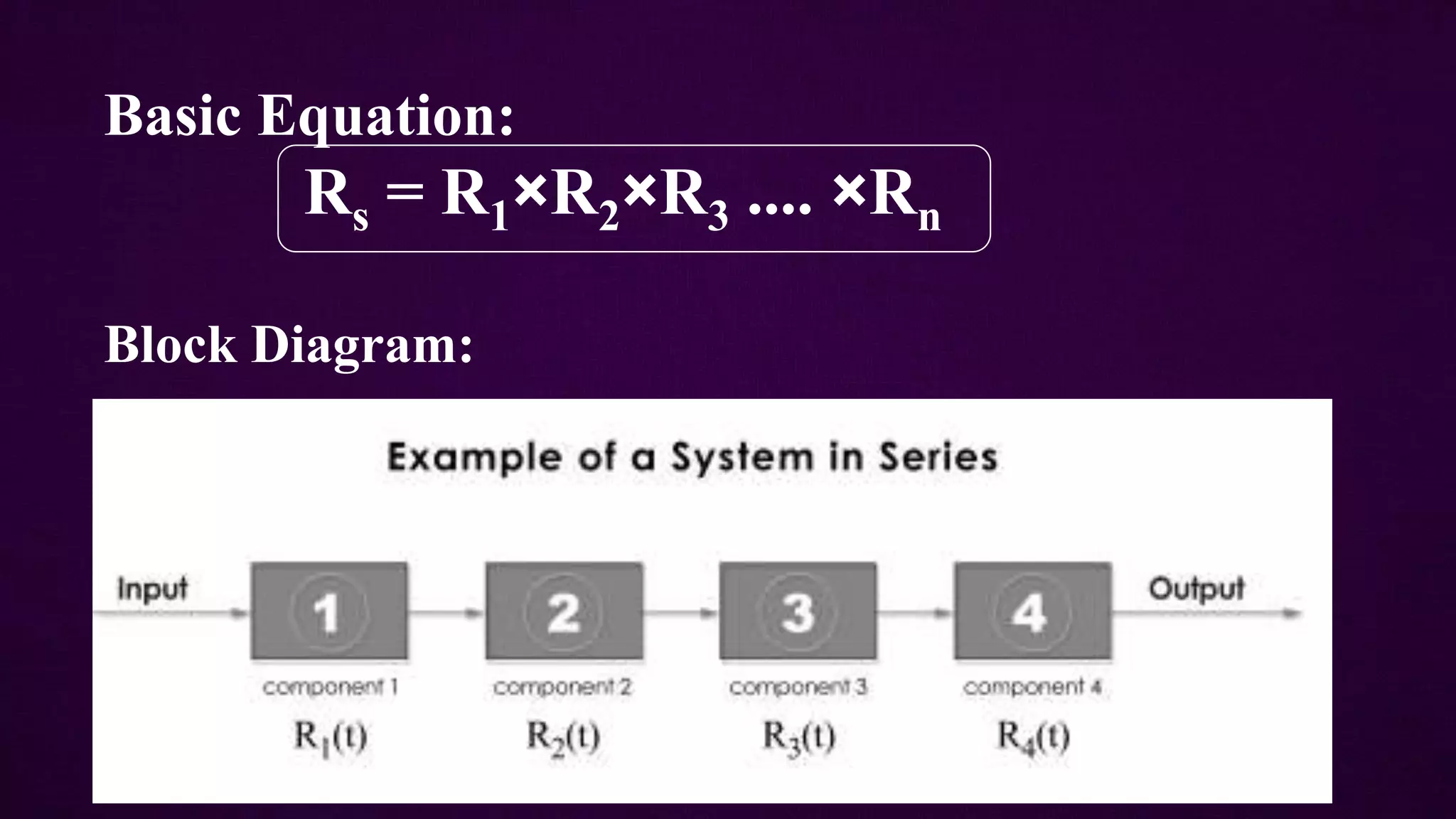

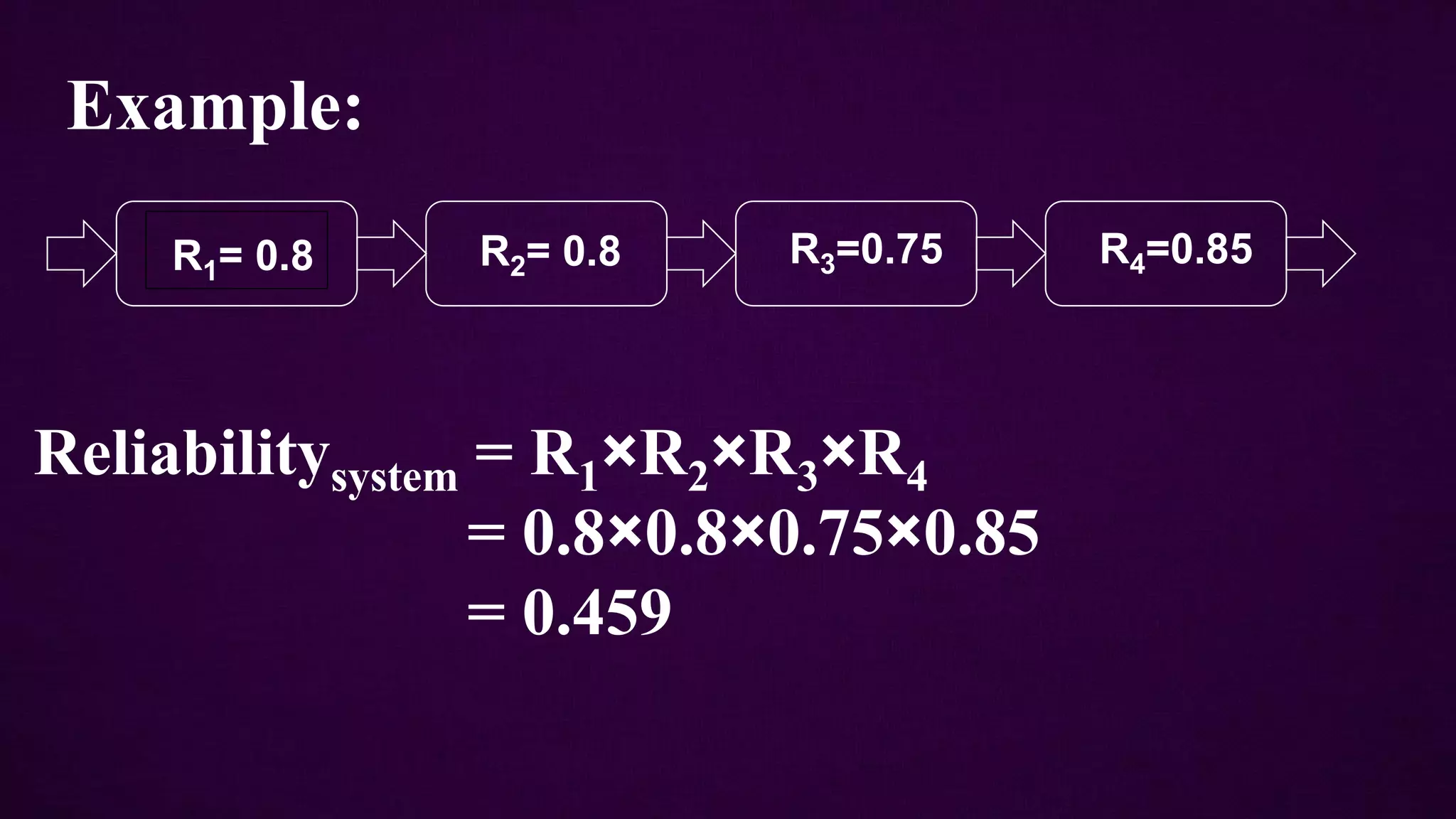

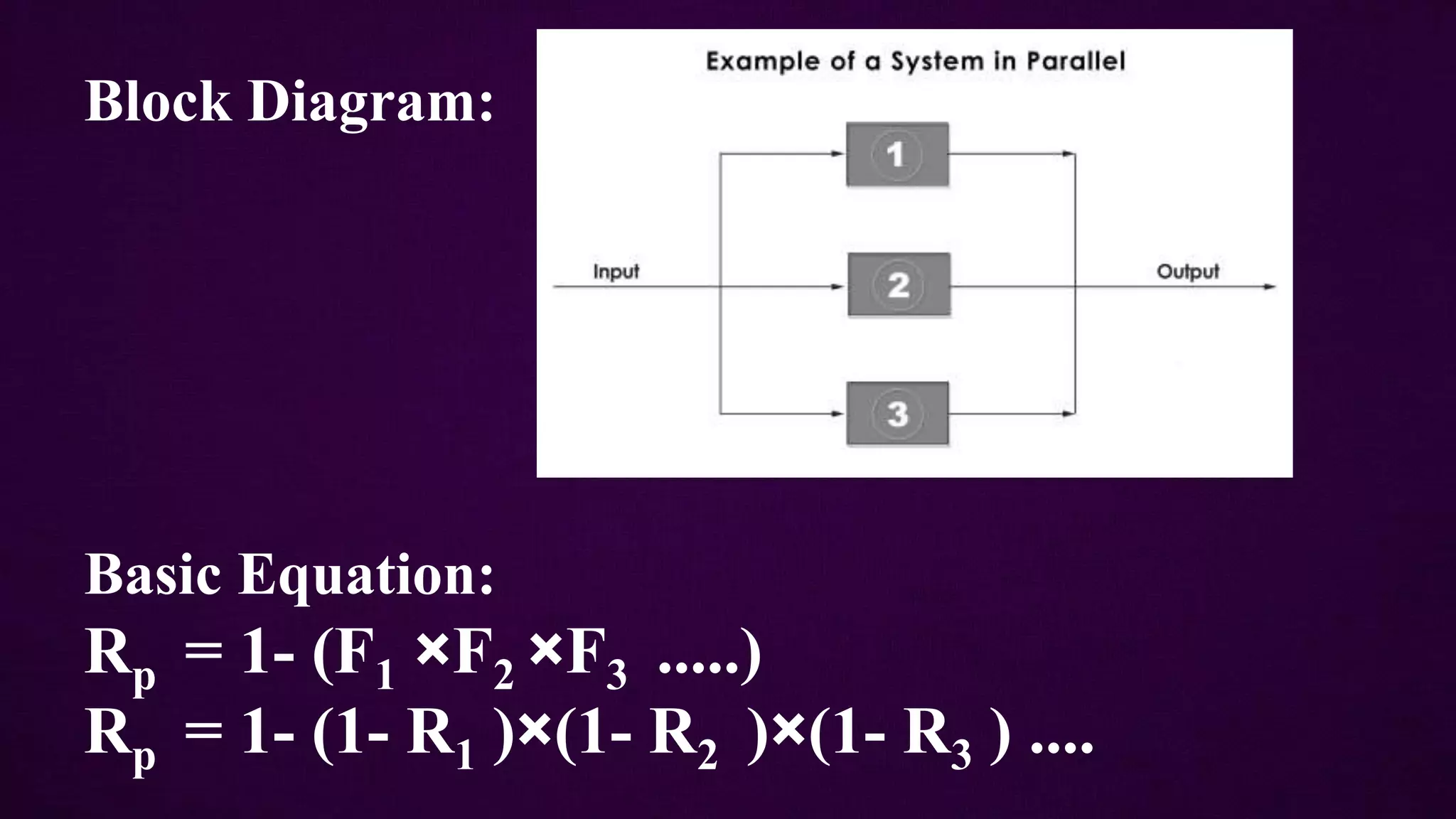

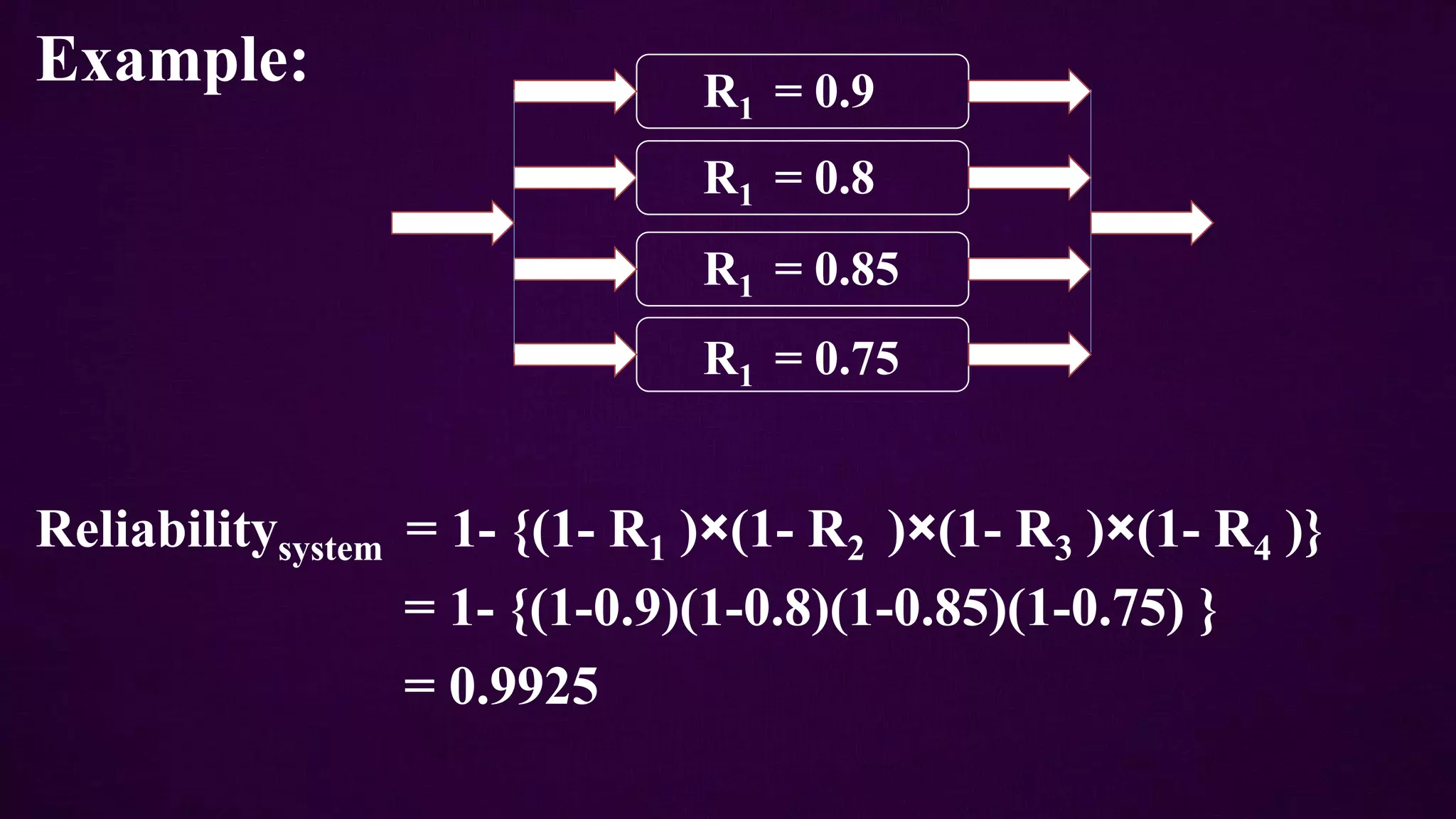

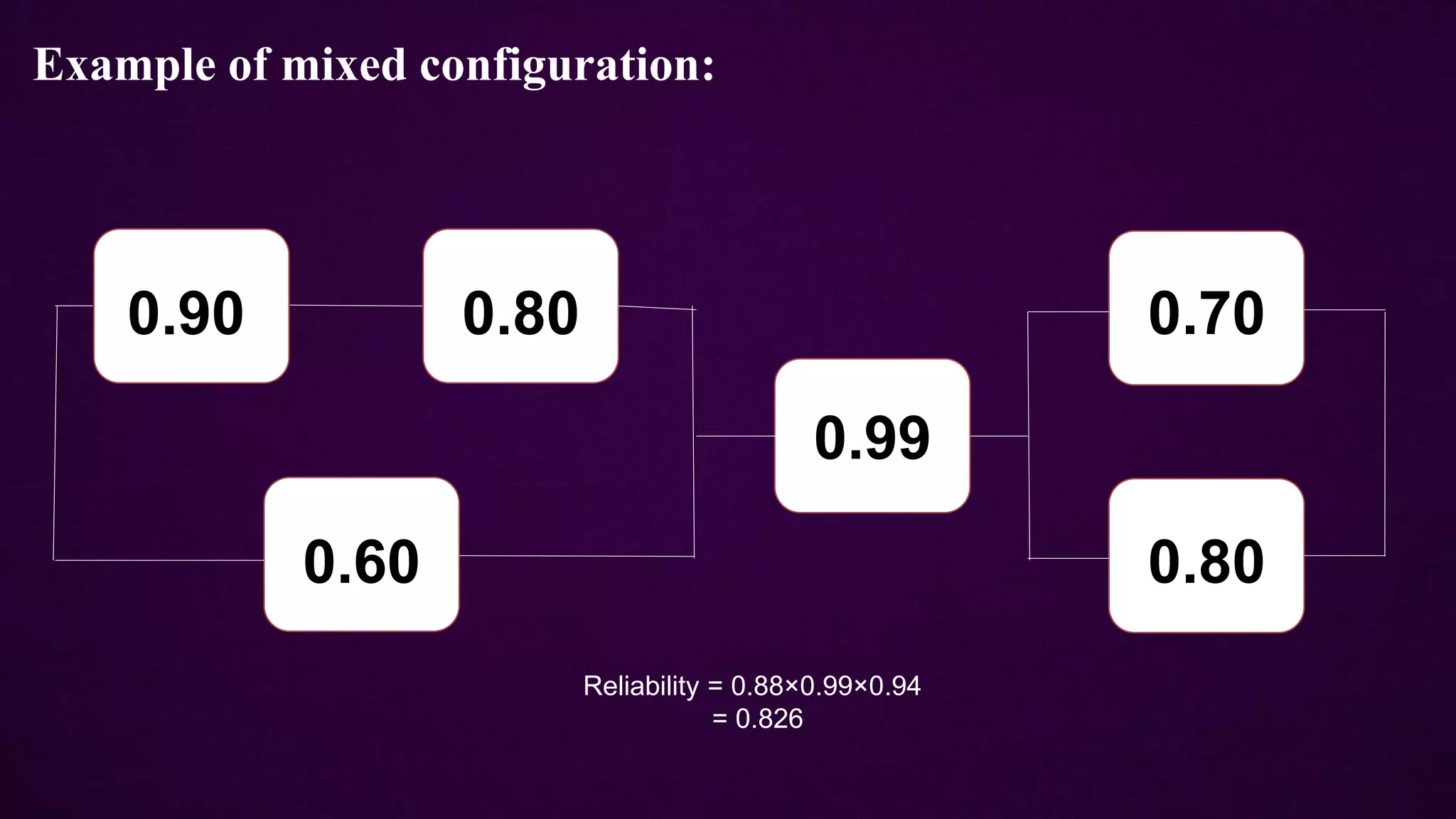

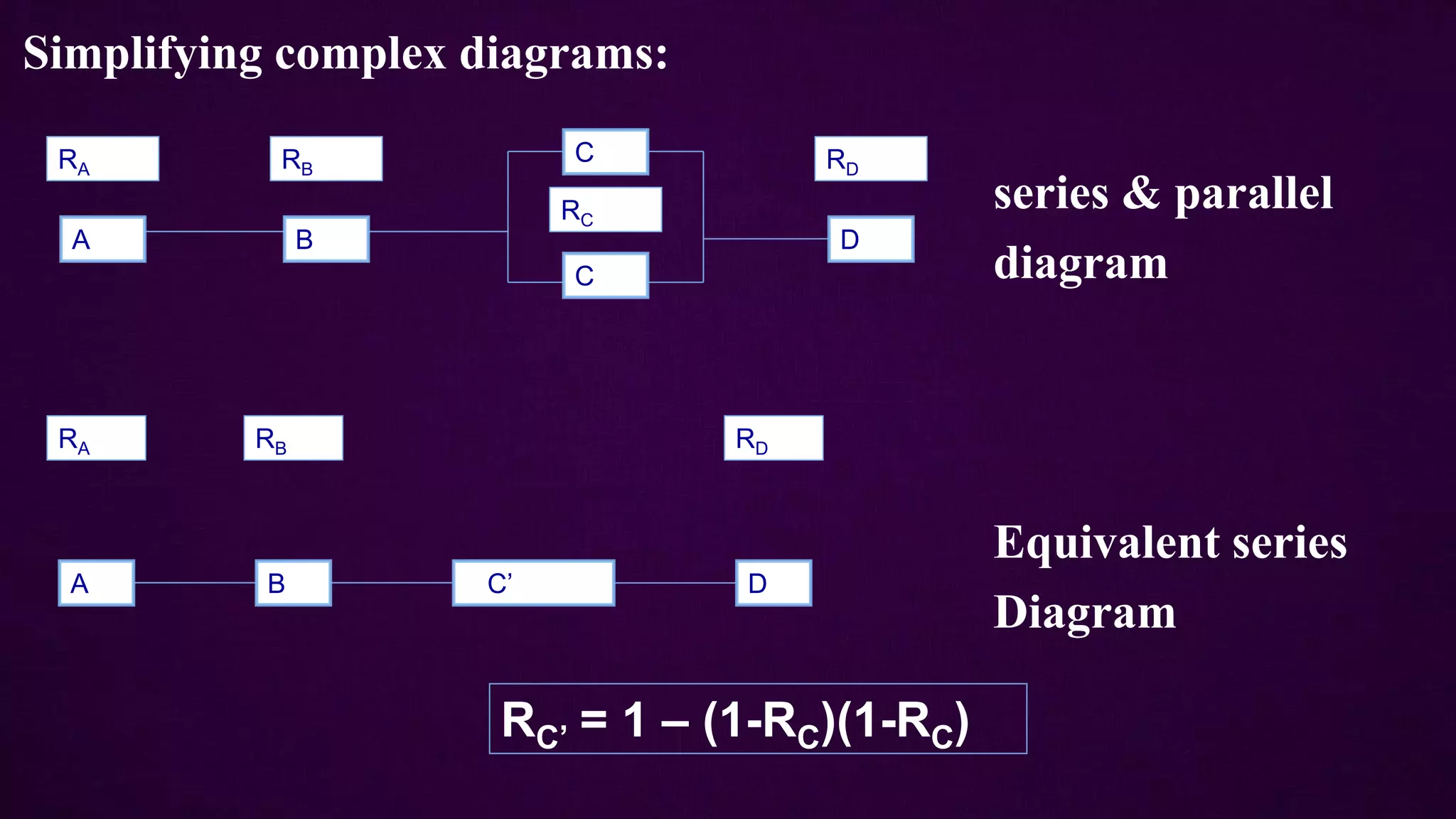

The document discusses system reliability, defining it as the performance of a system made up of various components configured in series, parallel, or mixed arrangements. It provides methods for calculating reliability factors, emphasizing the importance of component quality and arrangement on overall system performance. Key concepts include the behaviors of series and parallel configurations, their advantages and disadvantages, and the basic equations used for determining reliability in different set-ups.