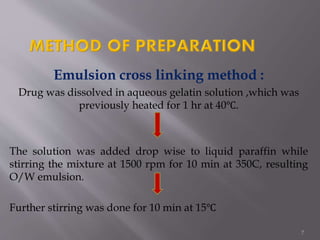

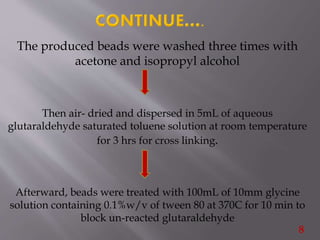

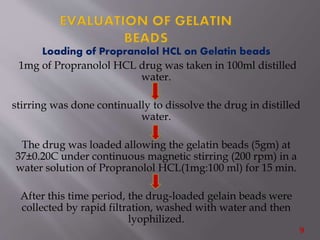

This document discusses using gelatin beads as a sustained release drug delivery system. Gelatin beads can provide sustained release of drugs over time by taking advantage of their large surface area and diffusion properties. The document describes preparing and evaluating propranolol HCl loaded gelatin beads using natural polymers gelatin and fish gelatin crosslinked with glutaraldehyde. The beads were evaluated for loading efficiency, yield, in vitro drug release, and stability over 3 months of accelerated conditions. Overall, the document proposes that gelatin beads can serve as a biocompatible drug delivery system for sustained drug release.