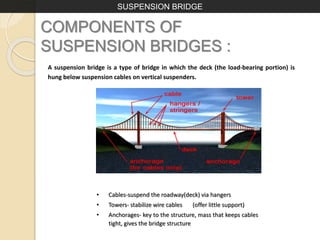

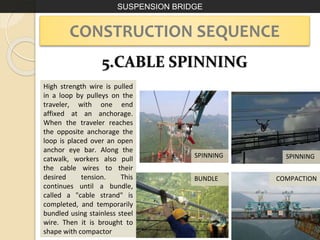

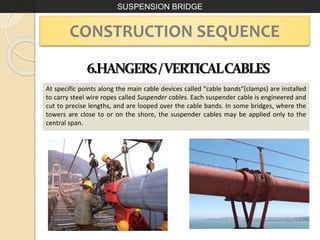

The document provides an overview of suspension bridges and cable-stayed bridges, detailing their components, construction methods, and historical development. It discusses the design features, forces acting on the bridges, and the various stages of construction for both types. Additionally, it highlights notable suspension bridges around the world and their respective spans.