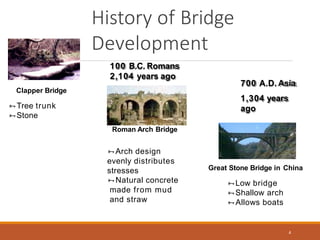

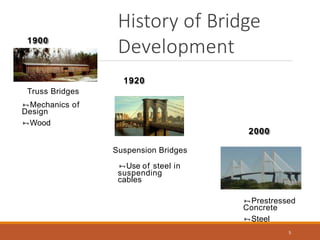

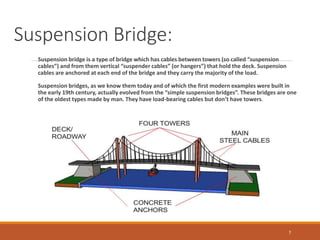

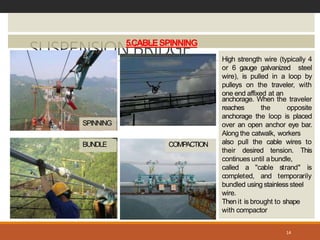

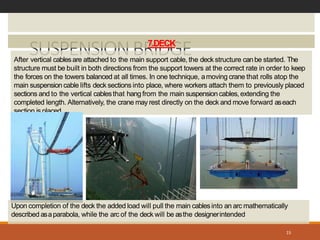

This document provides information about a presentation on suspension bridges given by five students. The presentation covers the history and development of bridges, defines the key components of suspension bridges, and describes the construction process. It discusses different types of suspension bridges and highlights advantages like achieving long spans with less material, as well as disadvantages like needing to prevent wind vibrations. The presentation aims to educate about structural analysis of suspension bridges.