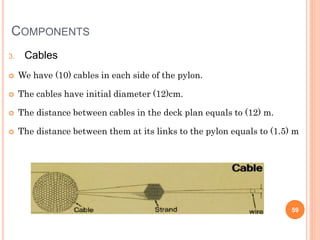

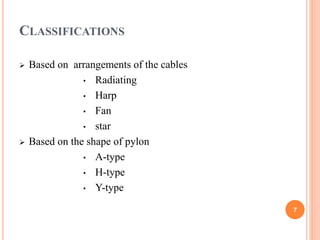

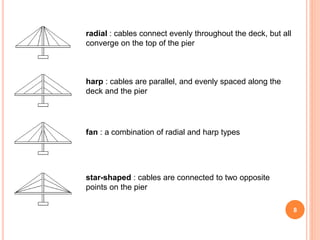

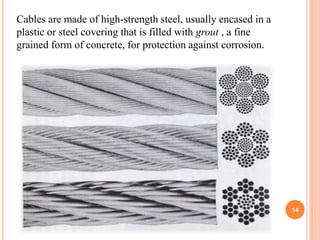

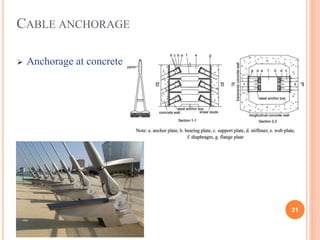

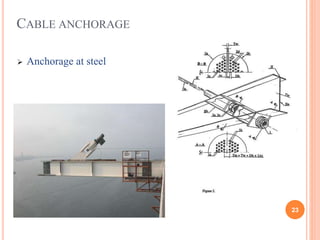

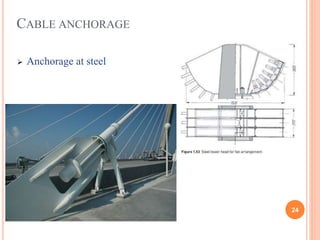

This document provides an analysis and design overview of a cable-stayed bridge project. It introduces cable-stayed bridges and their components, including pylons, decks, cables, and bearings. The project involves the design of a three-span cable-stayed bridge with two 130m pylons and an 80-cable system arranged in a double plane configuration. The bridge deck is 28m wide with 6 lanes and consists of I-girders, X-girders, and stringers. Cables are initially 12cm in diameter and spaced 12m apart. Bridge components and construction are further described. Tests on cable-stayed bridge models are also outlined.

![SLIDING BEARINGS

46

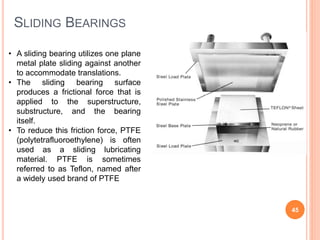

• Sliding Bearings be used alone

or more often used as a

component in other types of

bearings

• Pure sliding bearings can only

be used when the rotations

caused by the deflection at the

supports are negligible. They

are therefore limited to a span

length of 15 m or less by

ASHTTO [10.29.1.1]](https://image.slidesharecdn.com/cablestayedbridge-150719103331-lva1-app6892/85/Cable-stayed-bridge-46-320.jpg)